Preparation method of hydrogen tungsten bronze/ultra-microporous flexible carbon cloth, and products and applications

A hydrogen tungsten bronze and ultra-microporous technology is applied in the preparation of hydrogen tungsten bronze/ultra-microporous flexible carbon cloth, which can solve the problems of large difference in theoretical capacitance, limited application, poor conductivity of metal oxides, etc. The effect of increasing active specific surface area and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1: Preparation of ultra-microporous flexible carbon cloth

[0042] Commercial carbon cloth (Shanghai Hesen Carbon Cloth Co., Ltd., HCCP330) was washed with deionized water, calcined in an atmosphere with a volume ratio of nitrogen to oxygen of 100:2, and maintained at 1000 °C for 2 hours to obtain ultra-microporous flexible carbon cloth.

Embodiment 2

[0043] Embodiment 2: the preparation of hydrogen tungsten bronze / ultramicroporous flexible carbon cloth

[0044] Wash the ultra-microporous flexible carbon cloth prepared in Example 1 with alcohol and water, configure a 0.1M ammonium metatungstate solution, impregnate the ultra-microporous flexible carbon cloth in it, and ultrasonicate it for a reaction time of 2 hours. Calcined in nitrogen at 800°C and stayed for 4 hours to obtain H X WO 3 / Ultra-microporous flexible carbon cloth.

[0045] SEM of the resulting product see figure 1 , showing that H X WO 3 With the morphology of nanowires, the scanning electron microscope under high magnification can see figure 2 , indicating that the nanowires grow uniformly around the carbon fibers.

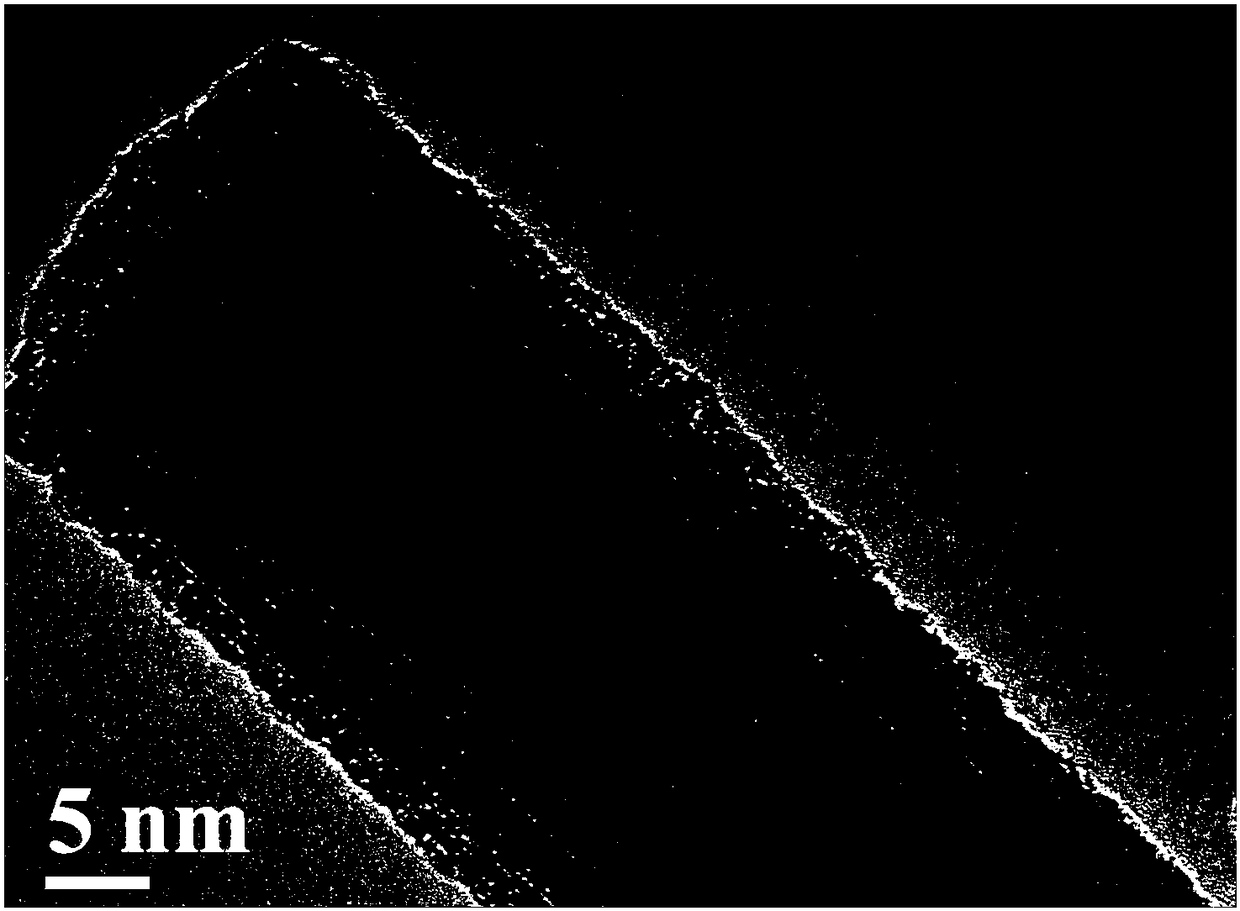

[0046] See HRTEM image 3 , indicating that the nanowires have surface and internal oxygen vacancies.

[0047] XRD characterization see Figure 4 , the card number is pdf: 42-1260, and the description is H 0.23 WO 3 , H 0.23 WO 3Th...

Embodiment 3

[0050] Example 3: Preparation of hydrogen tungsten bronze / ultramicroporous flexible carbon cloth

[0051] Wash the ultra-microporous flexible carbon cloth prepared in Example 1 with alcohol, wash it with water, configure a 5M ammonium metatungstate solution, impregnate the ultra-microporous flexible carbon cloth in it, and ultrasonicate the reaction time for 2 hours. Calcined in nitrogen at 700°C and stayed for 2 hours to obtain H X WO 3 / Ultra-microporous flexible carbon cloth.

[0052] The SEM morphology of the resulting product is as Figure 8 Shown, H X WO 3 is the shape of the nanowire, H X WO 3 The load is uniform, and the load can be as high as 8mg / cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com