A kind of flexible polyaniline-based composite film and its preparation method, supercapacitor

A polyaniline-based, composite film technology, applied in the field of composite materials, can solve the problems of low area-specific capacitance, limited mass load, high cost of carbon fiber paper, and achieve the effect of simple preparation method, enhanced rate performance, and high area capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below with reference to the accompanying drawings and in combination with preferred embodiments.

[0041] Materials used in the following examples Unless otherwise specified, the chemical substances used in the experiment were purchased from Sigma-Aldrich Co., USA, and the "ambient temperature" described herein is Refers to 18-26°C.

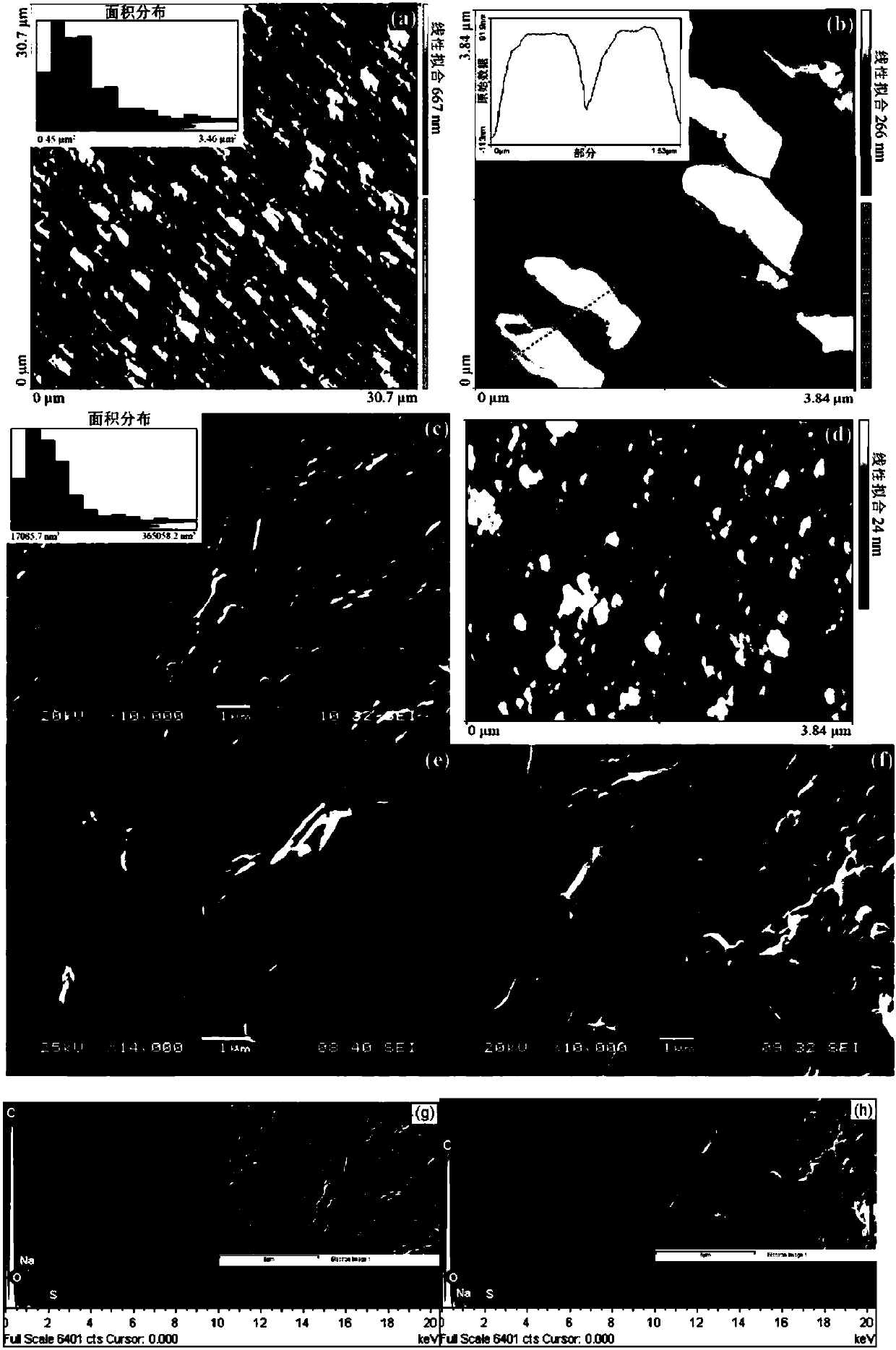

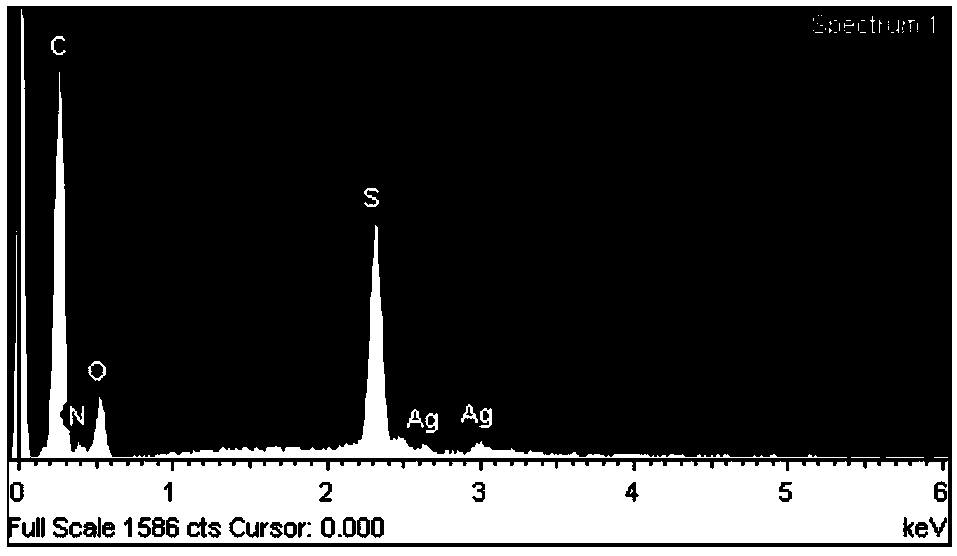

[0042] The preparation method of the flexible polyaniline-based composite membrane in the specific embodiment of the present invention and the performance test of the obtained flexible polyaniline-based composite membrane etc. include the following process:

[0043] 1. Preparation of exfoliated graphite (exfoliated graphite, ExG, exfoliated graphite can also be called graphene)

[0044] In a fume hood, two graphite rods (diameter 6.3 mm) were placed in a 0.1 M sodium sulfate aqueous solution as an anode and a cathode, respectively, with a distance of 1 cm. A voltage (12V) was applied for el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com