Modeling system of desktop type three-dimensional virtual maintenance model

A three-dimensional virtual and virtual maintenance technology, applied in 3D modeling, image data processing, special data processing applications, etc., can solve problems such as equipment loss, large equipment consumption, and difficult visual perception, so as to save costs and improve Quality, effect of shortening time for training

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The so-called desktop three-dimensional virtual maintenance is the use of computer graphics, virtual reality and other technologies. The modeling system of the desktop three-dimensional virtual maintenance model of the present invention uses a computer to combine related equipment hardware and virtual software to realize real-time maintenance of entities in a virtual environment. Simulation of equipment, system for maintenance training of actual installation. It can provide an intuitive simulation environment for equipment operation training, maintenance operation training, etc., thereby effectively shortening the training time, greatly improving the quality of training, and saving training costs.

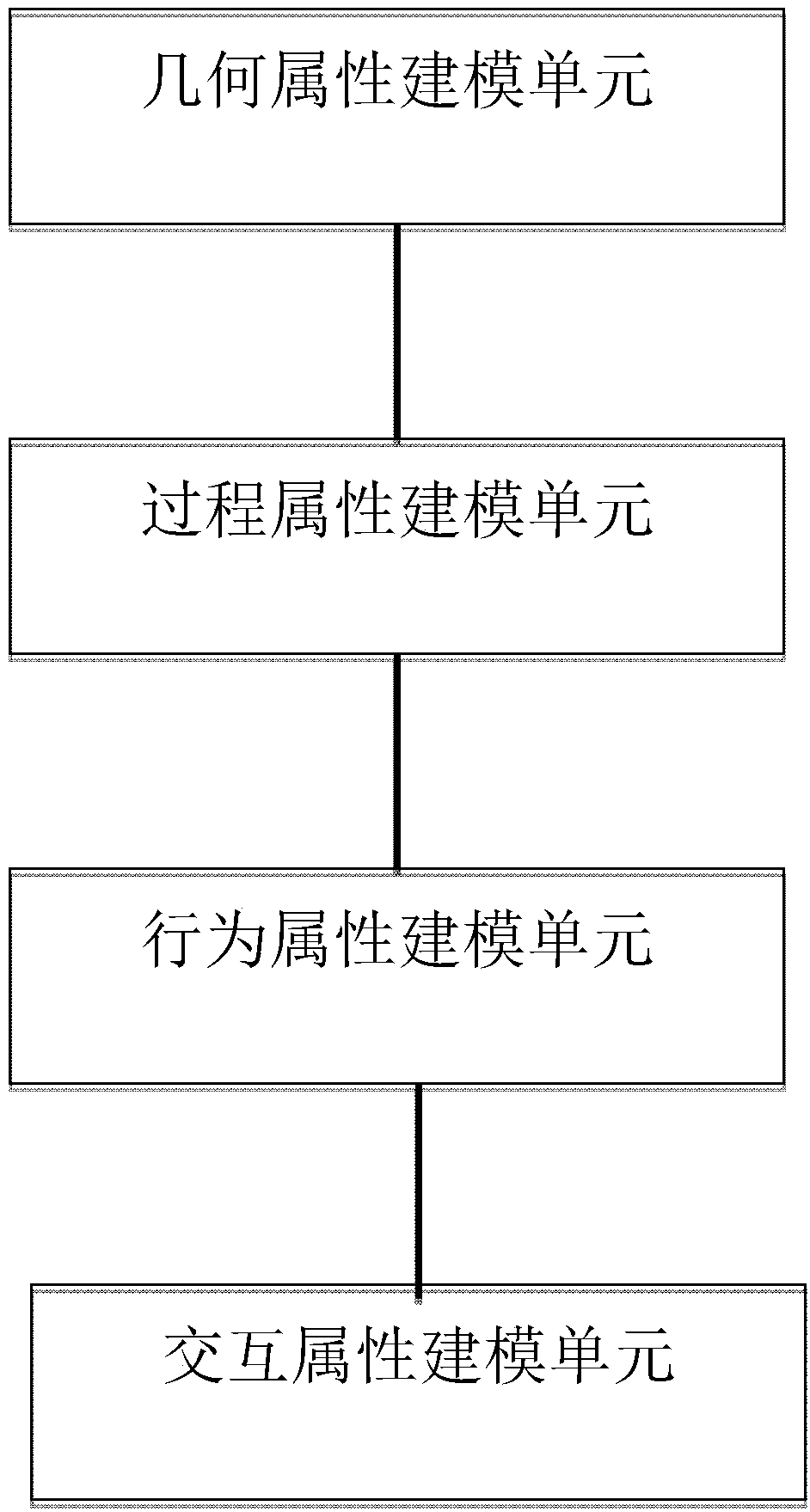

[0031] Specifically, the present invention provides a desktop three-dimensional virtual maintenance model modeling system, including:

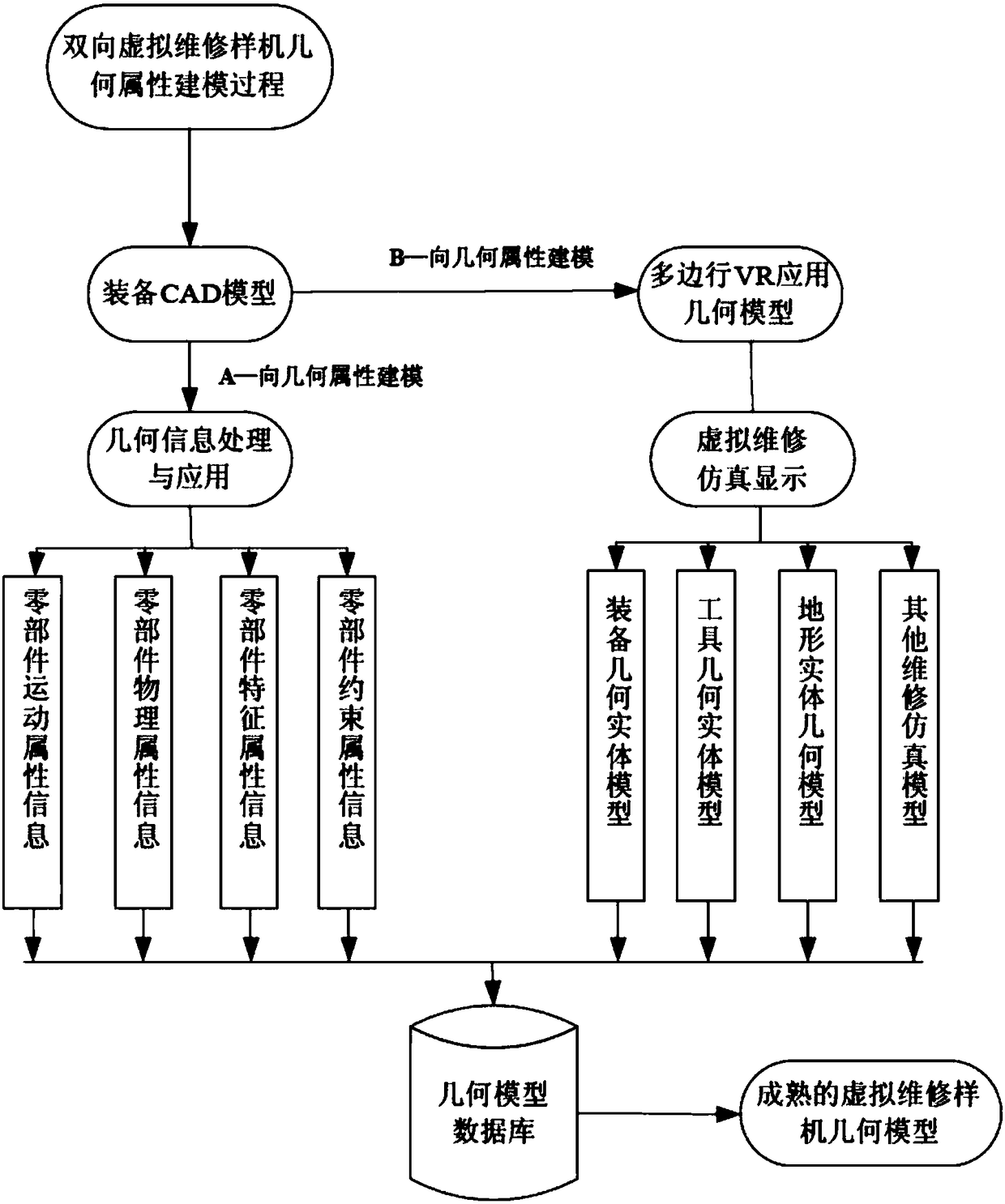

[0032] The geometric attribute modeling unit is used to draw the shape structure of the virtual maintenance object and establish the constr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com