Gaseous water molecule trapping and electrolyzing device, manufacturing method and application in electrochemical dehumidification

A technology for capturing electrolyzed and gaseous water, applied in applications, household heating, household appliances, etc., can solve the problems of atmospheric ozone layer destruction, difficult maintenance, long dehumidification time, etc. The effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

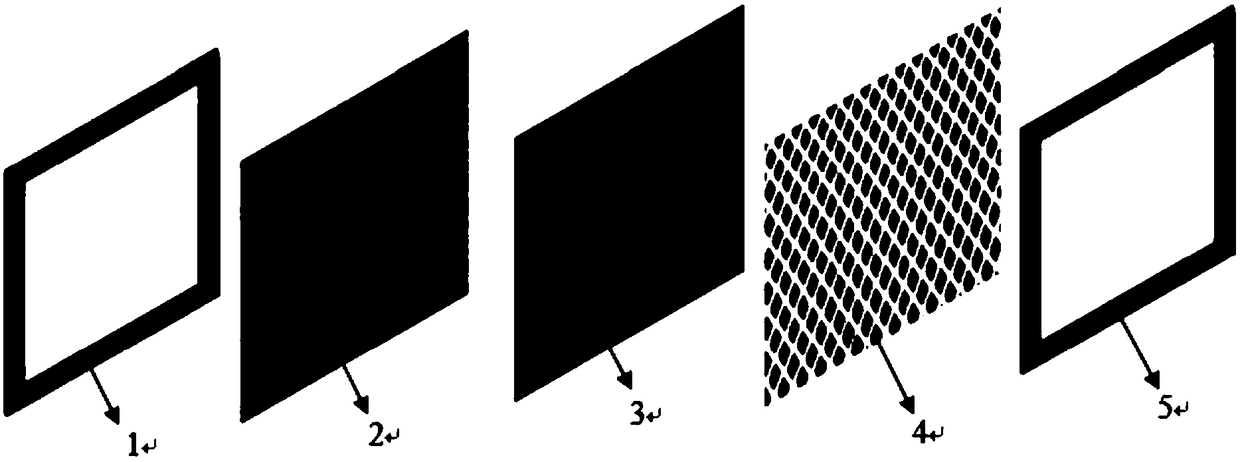

[0026] Such as figure 1 As shown, a gaseous water molecule trapping electrolysis device includes a cathode collector frame 1, a hydrogen diffusion layer 2, a hydrogen catalytic layer, a solid polymer proton exchange membrane 3, a water molecule trapping and catalytic oxidation layer, Anode mesh 4 and anode current collecting frame 5, the anode current collecting frame 5 is made of platinum-plated metal titanium, and the shape is square; the anode mesh 4 is made of 80-mesh flat titanium mesh; the water molecule capture and catalytic oxidation layer pass through The nano-iridium oxygen evolution catalyst is mixed with a binder with proton exchange function and coated on one side of the solid polymer proton exchange membrane 3. The mass ratio of nano-iridium to binder is 1:0.2; the solid polymer proton The loading capacity of nano-iridium on the exchange membrane 3 unit area is 0.5mg / cm 2 The hydrogen diffusion layer 2 is carbon paper, and the hydrogen catalytic layer is formed ...

Embodiment 2

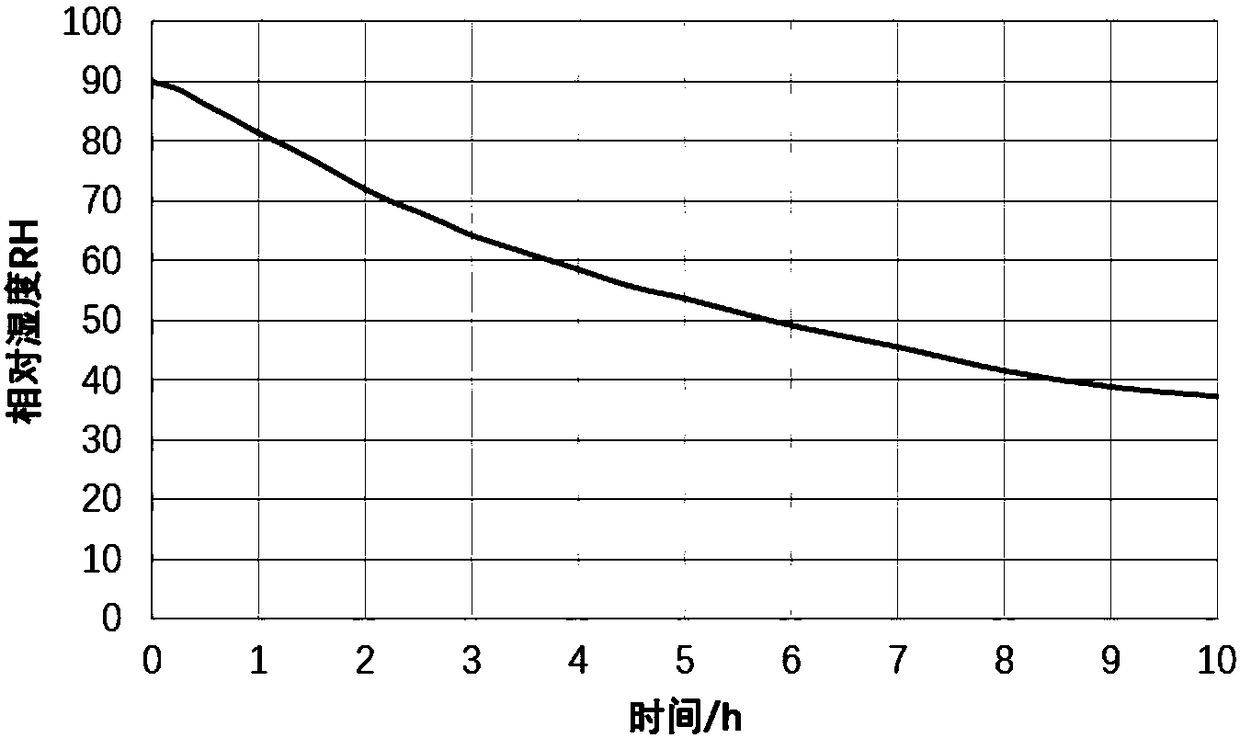

[0030] The difference between embodiment 2 and embodiment 1 is that the mass ratio of nano-iridium and binder is 1: 0.5; the loading capacity of nano-iridium on the solid polymer proton exchange membrane 3 unit area is 4mg / cm 2 , the mass ratio of nano-platinum black to adhesive is 1:0.5, and the loading amount of nano-platinum black on carbon paper is 3mg / cm 2, when the gaseous water molecule trapping electrolysis device of Example 2 was applied to electrochemical dehumidification, within 10 hours, the humidity in the test box dropped from 90% to 48%, and its average power consumption was 0.55 watts.

Embodiment 3

[0032] The difference between embodiment 3 and embodiment 1 is that the mass ratio of nano-iridium and binder is 1: 0.8; the loading capacity of nano-iridium on the solid polymer proton exchange membrane 3 unit area is 8mg / cm 2 , the mass ratio of nano-platinum black to adhesive is 1:0.8, and the loading amount of nano-platinum black on carbon paper is 6mg / cm 2 , when the gaseous water molecule trapping electrolysis device of Example 3 was applied to electrochemical dehumidification, within 10 hours, the humidity in the test box dropped from 90% to 43%, and its average power consumption was 0.6 watts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com