Polyamine inhibitor for water-based drilling fluid and preparation method of polyamine inhibitor

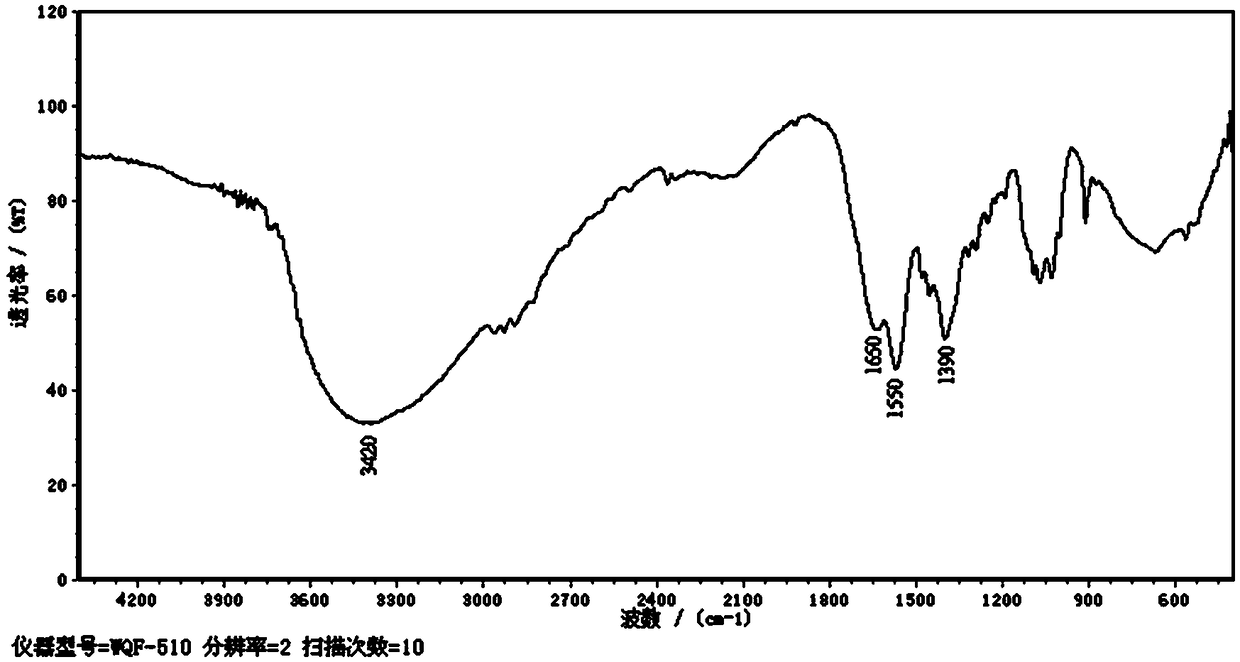

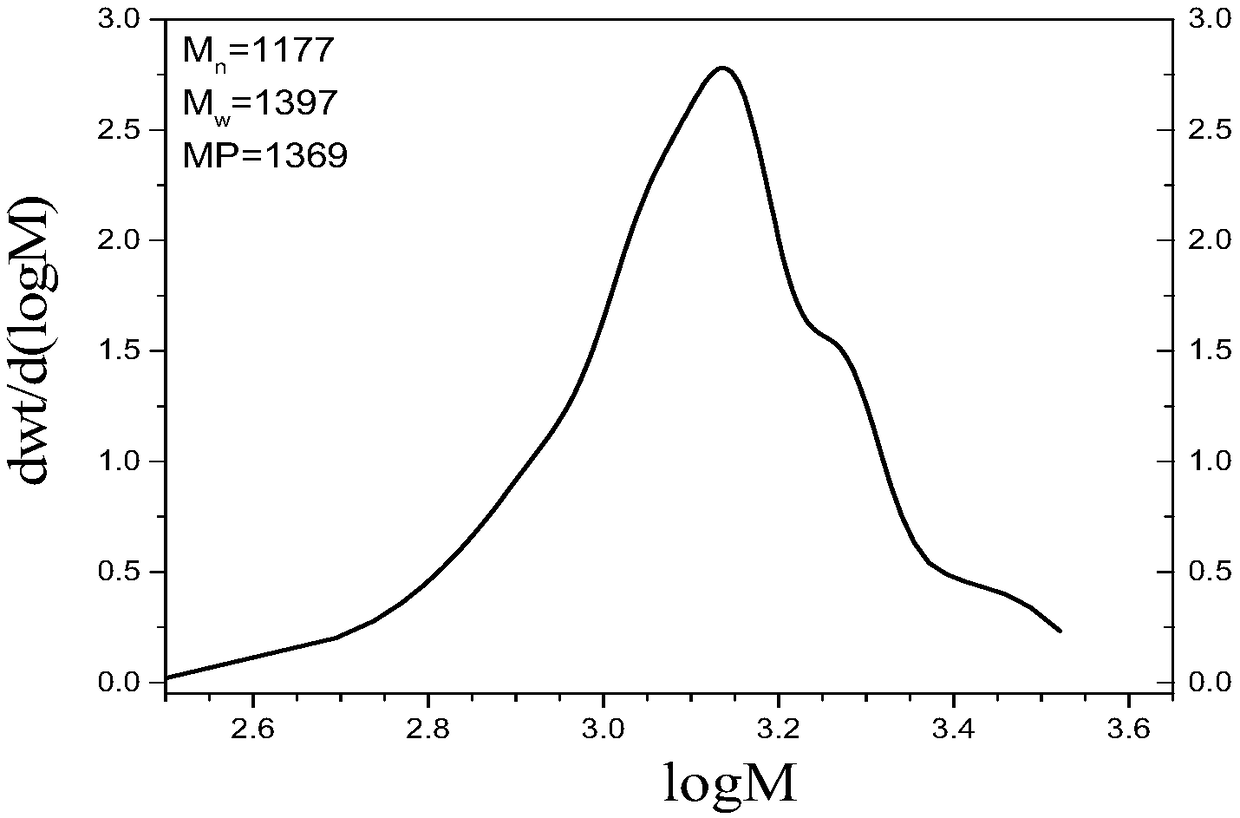

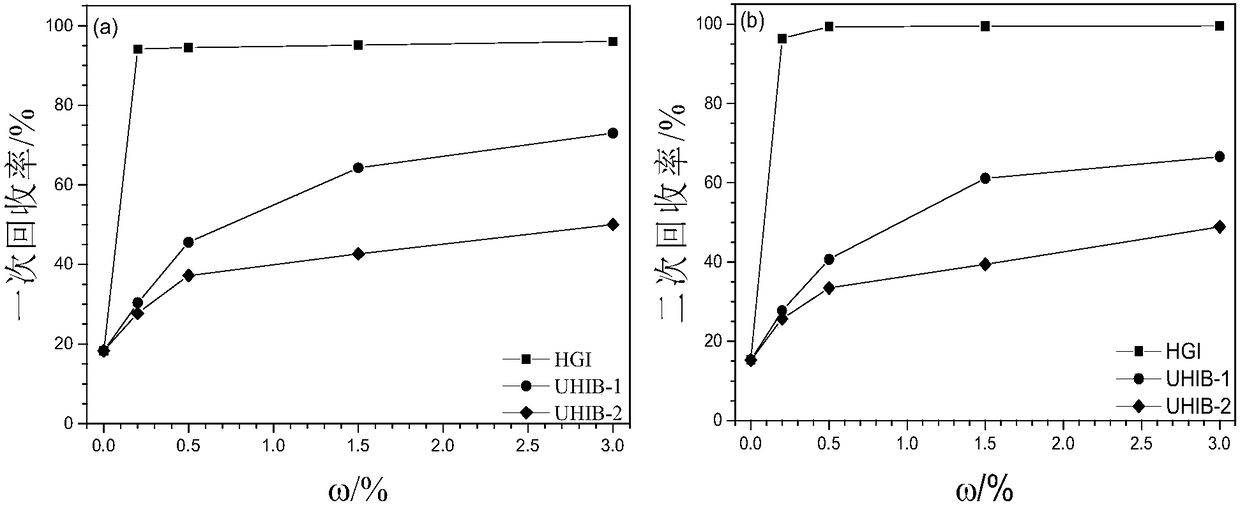

A technology of polyamine inhibitor and water-based drilling fluid, which is applied in the field of oil drilling, can solve the problems of high cost and poor environmental protection performance, and achieve the effect of inhibiting hydration dispersion and inhibiting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1: Weigh the following components by mass, maleic anhydride 78g, triethanolamine 213g, glacial acetic acid 10g, tap water 350g;

[0034] Step 2: place the weighed maleic anhydride and triethanolamine in the reactor at normal temperature;

[0035] Step 3: Raise the temperature in the reactor to 85°C within 40 minutes, and keep the temperature for 30 minutes;

[0036] Step 4: Continue to heat up to 180°C after the insulation, while keeping the pressure in the reactor at 20mm mercury column state with a vacuum pump, and react for 4 hours;

[0037] Step 5: After the reaction, the pressure was released by cooling and the temperature was lowered to 90°C.

[0038] Step 6: After reaching the required temperature, add glacial acetic acid and tap water, and prepare the polyamine inhibitor after 2 hours of reaction.

Embodiment 2

[0040] Step 1: Weigh the following components by mass, maleic anhydride 75g, triethanolamine 210g, glacial acetic acid 8g, tap water 348g;

[0041] Step 2: place the weighed maleic anhydride and triethanolamine in the reactor at normal temperature;

[0042] Step 3: Raise the temperature in the reactor to 80°C within 40 minutes, and keep the temperature for 30 minutes;

[0043] Step 4: Continue to heat up to 180°C after the insulation, while keeping the pressure in the reactor at 20mm mercury column state with a vacuum pump, and react for 4 hours;

[0044] Step 5: After the reaction, the pressure was released by cooling and the temperature was lowered to 90°C.

Embodiment 3

[0046] Step 6: After reaching the required temperature, add glacial acetic acid and tap water, and prepare the polyamine inhibitor after 2 hours of reaction.

[0047] Step 1: Weigh the following components by mass, maleic anhydride 80g, triethanolamine 215g, glacial acetic acid 12g, tap water 352g;

[0048] Step 2: place the weighed maleic anhydride and triethanolamine in the reactor at normal temperature;

[0049] Step 3: Raise the temperature in the reactor to 90°C within 40 minutes, and keep the temperature for 30 minutes;

[0050] Step 4: Continue to heat up to 180°C after the insulation, while keeping the pressure in the reactor at 20mm mercury column state with a vacuum pump, and react for 4 hours;

[0051] Step 5: After the reaction, the pressure was released by cooling and the temperature was lowered to 90°C.

[0052] Step 6: After reaching the required temperature, add glacial acetic acid and tap water, and prepare the polyamine inhibitor after 2 hours of reaction. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com