A kind of tungsten bronze type single-phase multiferroic ceramic material and preparation method thereof

A technology of multiferroic ceramics and tungsten bronze, which is applied in the field of functional ceramic materials, can solve the problems of harsh reaction conditions, complex product phases, long reaction cycles, etc., and achieve improved application value, simple preparation process, and multiferroic properties. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A kind of preparation method of tungsten bronze type single-phase multiferroic ceramic material, the chemical formula of this material is Ba 4- 2x Ca 2x SM 2 Fe 2 Nb 8 o 30 , x=0.2, 0.4, 0.6 or 0.8, which includes the following steps:

[0031] (1) Weigh the corresponding mass of BaCO according to the molar ratio 3 , CaCO 3 、Sm 2 o 3 , Fe 2 o 3 and Nb 2 o 5 , to synthesize Ba 4- 2x Ca 2x SM 2 Fe 2 Nb 8 o 30 (x=0.2, 0.4, 0.6, 0.8), mix all weighed powders evenly to form a full batch;

[0032]Mix all the ingredients with zirconia balls and deionized water, then perform ball milling, drying and sieving in sequence to form a pure-phase ceramic powder after sieving;

[0033] (2) The pure-phase ceramic powder is made into a sample by cold isostatic pressing, and the prepared sample is sintered at high temperature to obtain a sintered sample;

[0034] (3) Grinding and cleaning the sintered sample obtained in step (2), uniformly coat the silver electrode sl...

example 1

[0041] (1) First mix raw materials according to molar ratio to form mixture A, wherein BaCO 3 and CaCO 3 The stoichiometric ratio is 9:1, respectively, Sm 2 o 3 , Fe 2 o 3 , Nb 2 o 5 The stoichiometric ratio is 1:1:4. Take the mixture A, zirconia balls and deionized water, mix them according to the mass ratio of 1:4:0.8, use a planetary ball mill for 20 hours, then dry them at 80°C for 14 hours, briquette them, and place them in a box furnace Incubate at 1200°C for 2 hours respectively, and set aside;

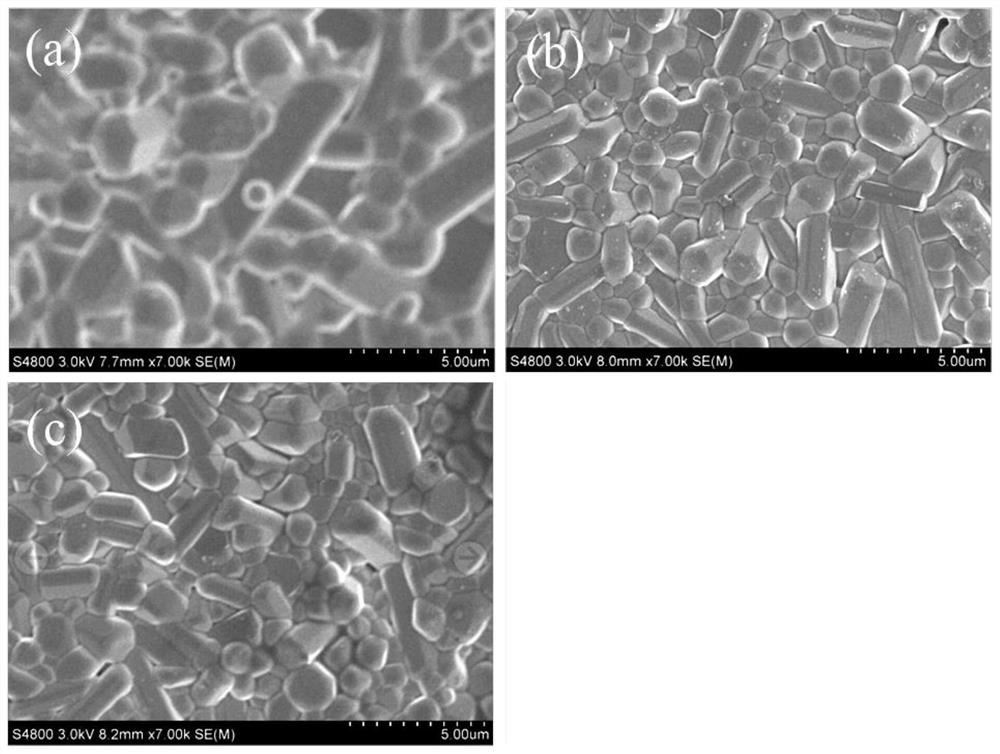

[0042] Grind the dried briquette through a 120 mesh sieve to form a sieve to obtain a pure phase of Ba 3.6 Ca 0.4 SM 2 Fe 2 Nb 8 o 30 Ceramic powder, the scanning electron microscope image of which is shown in figure 2 As shown in (a), short rod-shaped tungsten bronze grains can be obtained, and the compactness is good, so that the multiferroic properties of ceramics are greatly improved;

[0043] (2) The sieved material obtained in step (3) is pressed into a sa...

example 2

[0046] (1) First mix raw materials according to molar ratio to form mixture A, wherein BaCO 3 and CaCO 3 The stoichiometric ratio is 4:1, respectively, Sm 2 o 3 , Fe 2 o 3 , Nb 2 o 5 The stoichiometric ratio is 1:1:4. Take the mixture A, zirconia ball stone and deionized water, mix according to the mass ratio of 1:4:0.9, use planetary ball mill for 21h, then dry at 70°C for 15h, briquette, and place in a box furnace Incubate at 1200°C for 2 hours respectively, and set aside;

[0047] Grind the dried briquettes through a 200-mesh sieve to form a sieve to obtain a pure phase of Ba 3.2 Ca 0.8 SM 2 Fe 2 Nb 8 o 30 Ceramic powder, the scanning electron microscope image of which is shown in figure 2 As shown in (b), the steps of examples can be used to obtain short rod-shaped tungsten bronze grains, which greatly improves the multiferroic properties of ceramics;

[0048] (2) Press the sieved material obtained in step (1) into a sample by cold isostatic pressing under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com