Harmless refrigerating storage device

A kind of equipment and cold storage technology, which is applied in the field of harmless cold storage storage equipment, can solve hidden dangers, inconvenience and safety problems, and achieve the effects of ensuring cleanliness, improving the air environment, and preventing livestock corpses from slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

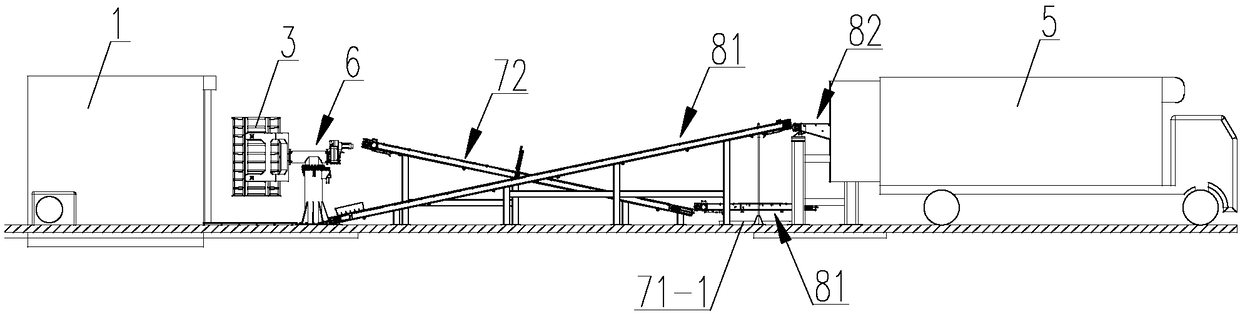

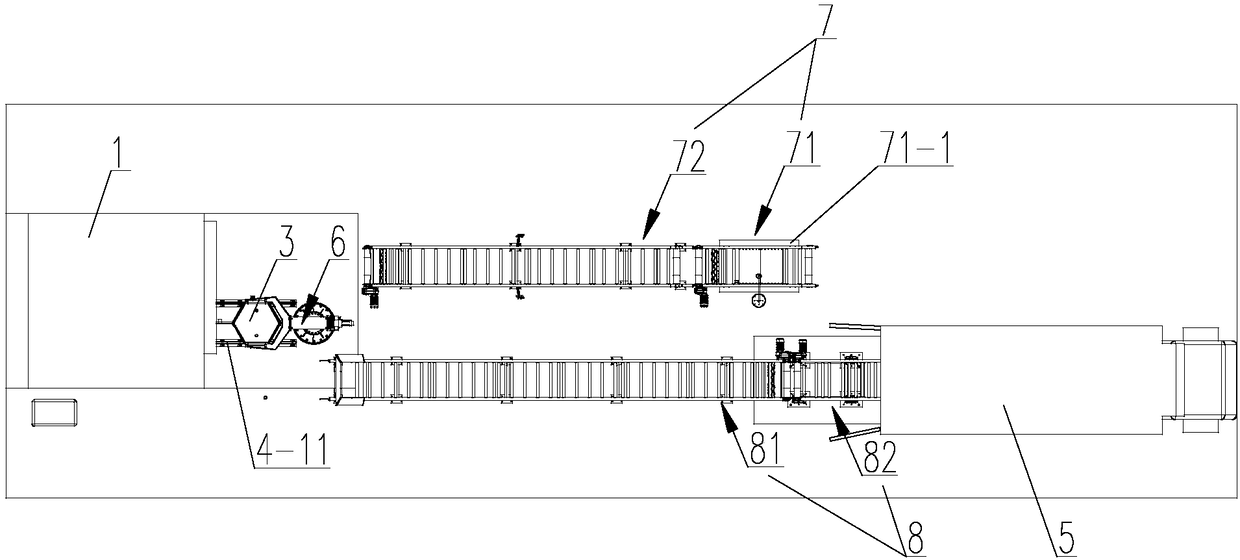

[0088] like figure 1 and 2 As shown, a harmless cold storage storage equipment is characterized in that: the cold storage storage equipment includes:

[0089] Cold storage 1, used for cold storage of livestock carcasses;

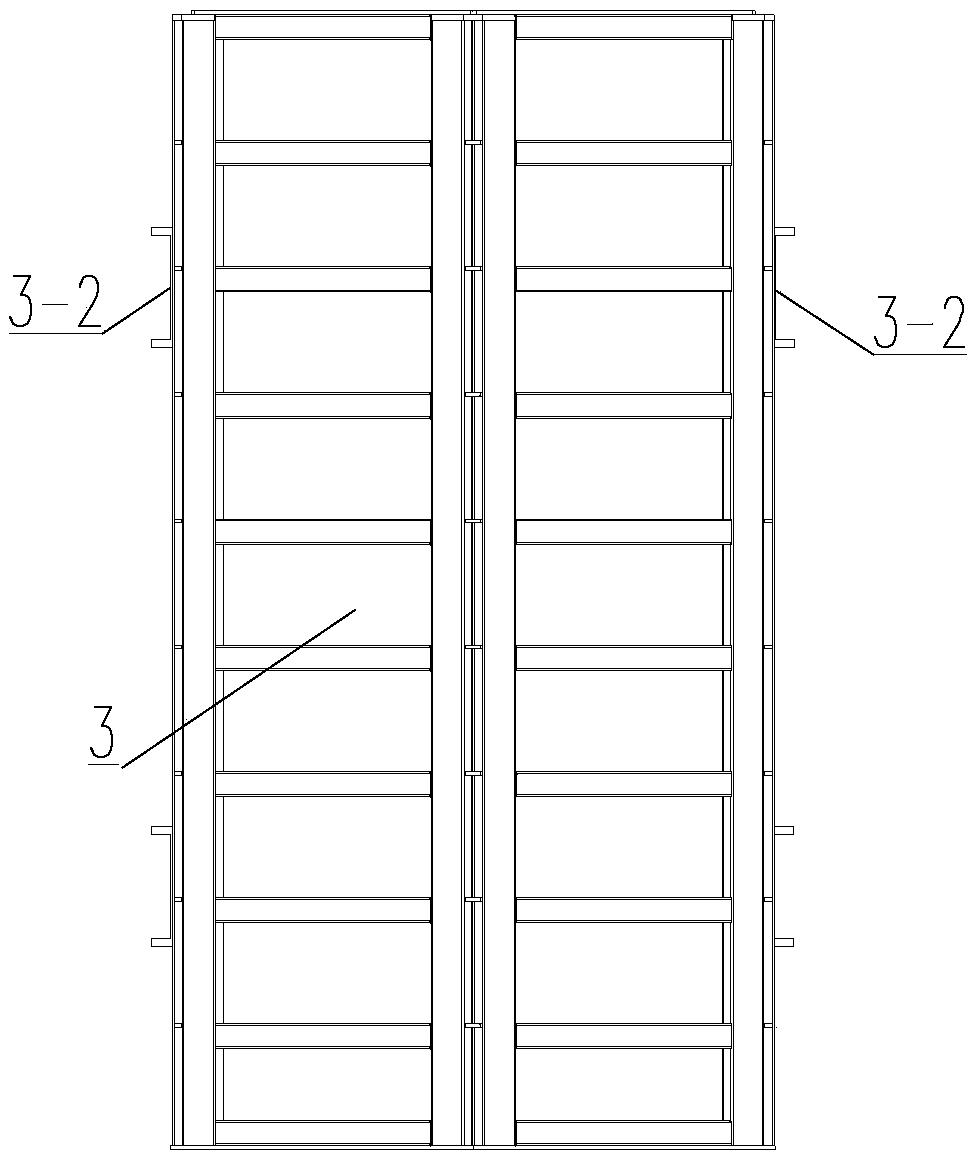

[0090] Feed bucket 3, is used for loading livestock carcass;

[0091] The rotary storage device is arranged in the cold storage 1, and the rotary storage device includes a turntable 2-1 for placing the material barrel 3 and a power assembly for driving the turntable 2-1 to rotate;

[0092] The self-running trolley 4 is used to transport the material barrel 3 into and out of the cold storage 1. The self-running trolley 4 has a fork 4-1 and a lifting assembly for placing the material barrel 3. The lifting assembly is used to drive the fork 4-1 to rise or fall. To realize taking out or placing the barrel 3 on the turntable 2-1;

[0093] The guide rail 4-11 is used to guide the self-running trolley 4, and one end of the guide rail 4-11 extends from the outsi...

Embodiment 2

[0129] The difference between embodiment 2 and embodiment 1 is: as Figure 5 and 6 As shown, the cross section of the material barrel 3 is hexagonal, and the upper surface of the turntable 2-1 is divided into several storage areas 2-11 for placing the material barrel 3 at equal intervals along its circumferential direction, and the upper surface of the turntable 2-1 It is divided into several storage areas 2-11 at equal intervals along its circumferential direction, and one end of the guide rail 4-11 located in the cold storage 1 is provided with a storage station. During the station, the cargo fork 4-1 on the self-running trolley 4 is located at a storage area 2-11 closest to the entrance and exit of the cold storage 1 on the turntable 2-1, and the position of the guide rail 4-11 relative to the turntable 2-1 is set as When the self-running trolley 4 moves to the storage station, the innermost outer surface of the barrel 3 on the self-running trolley 4 faces the center of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com