Concrete construction method for engineering

A construction method and concrete technology, which is applied in the construction of engineering concrete and the field of engineering mixture, can solve problems such as changes in concrete quality and affect the quality of engineering construction, and achieve high space utilization, reduce the center of gravity of the car body, and ensure quality requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below through specific implementation manners in conjunction with the accompanying drawings.

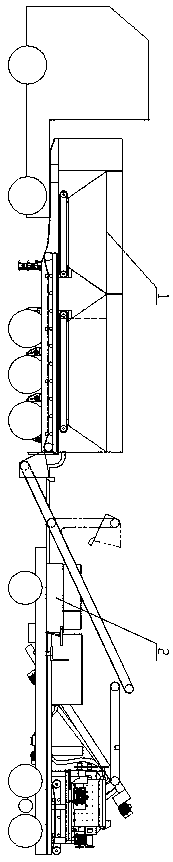

[0028] A concrete construction method for engineering, the method involves a multi-material supply feeder 1 and a self-driven mixing train 2, to facilitate a better understanding of the present invention, first of all, the specific details of the multi-material supply feeder 1 and the self-driven mixing train 2 The structure is introduced separately.

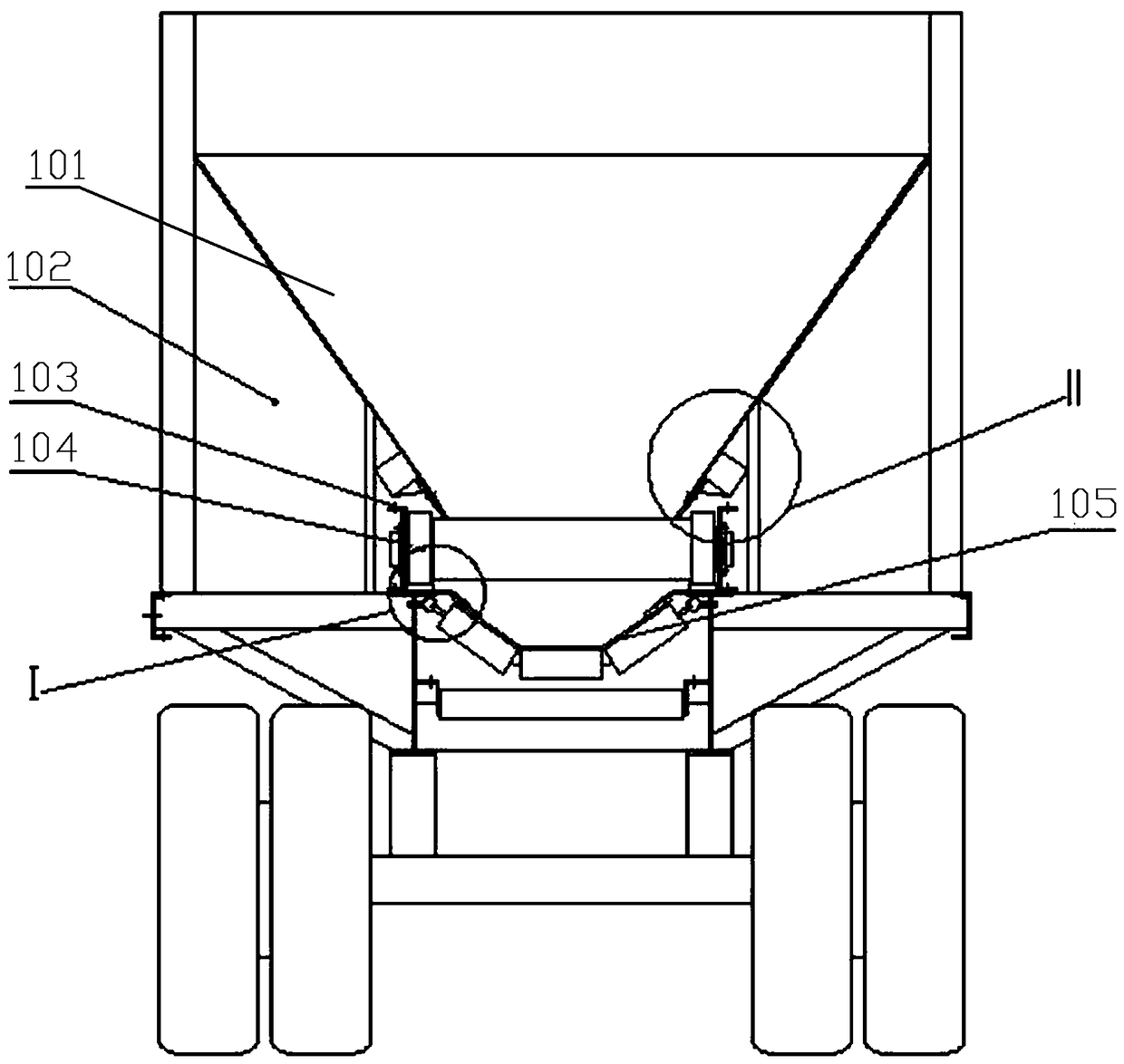

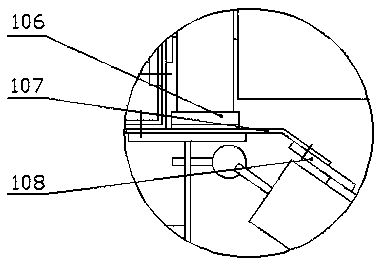

[0029] like figure 2 As shown, the multi-material supply truck 1 includes a chassis and a plurality of material bins 101 arranged along the length direction of the chassis. A material guide device I is installed at the bottom of the material bin 101 and a primary conveying device is provided at the outlet of the material bin 101. , a material guide II and a secondary conveying device are provided below the primary conveying device, the secondary conveyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com