paper cutter

A paper cutter and cutting mechanism technology, applied in metal processing, etc., can solve the problems of cumbersome operation, low efficiency, and low degree of automation, and achieve the effect of simplifying operation steps and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

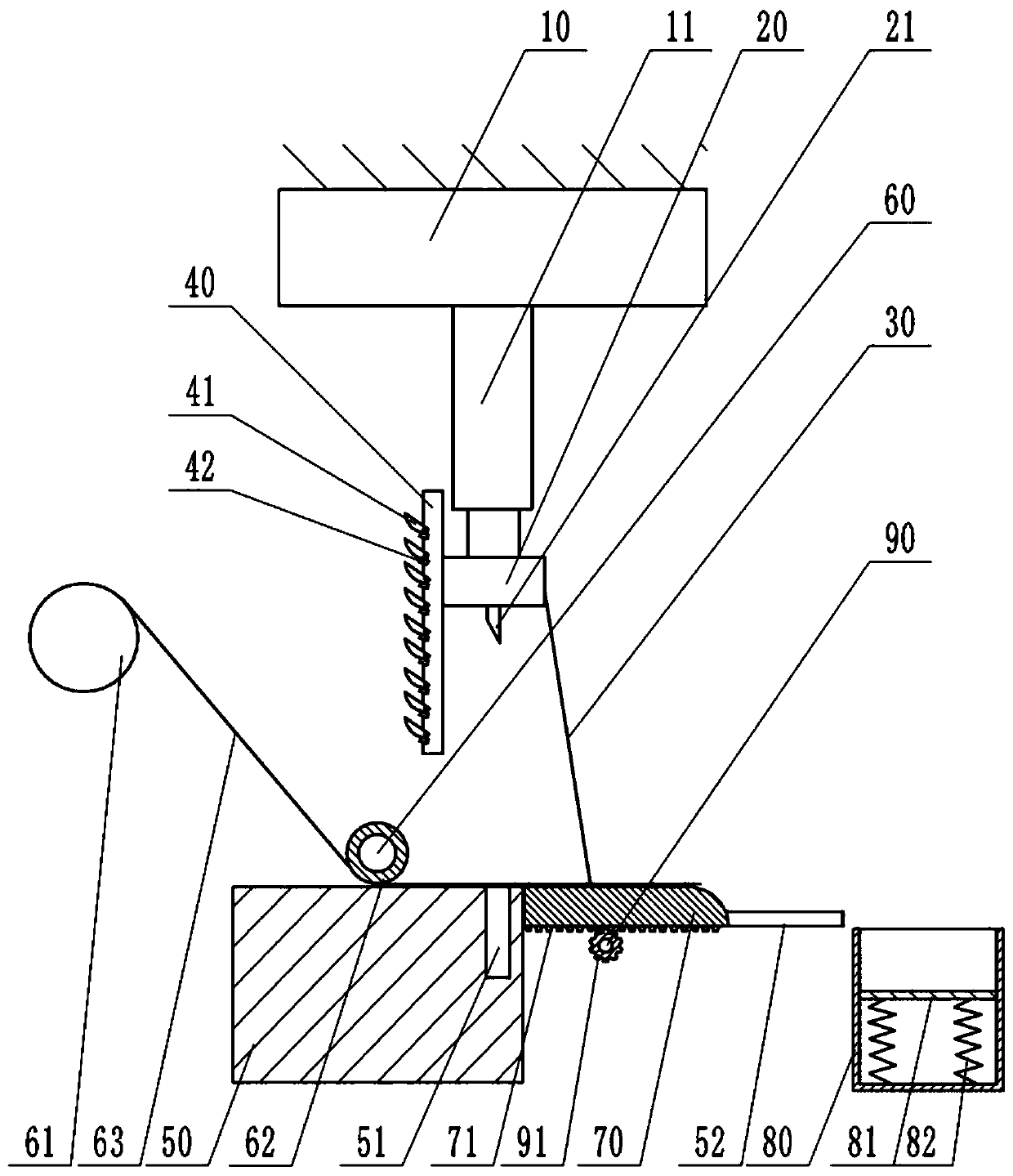

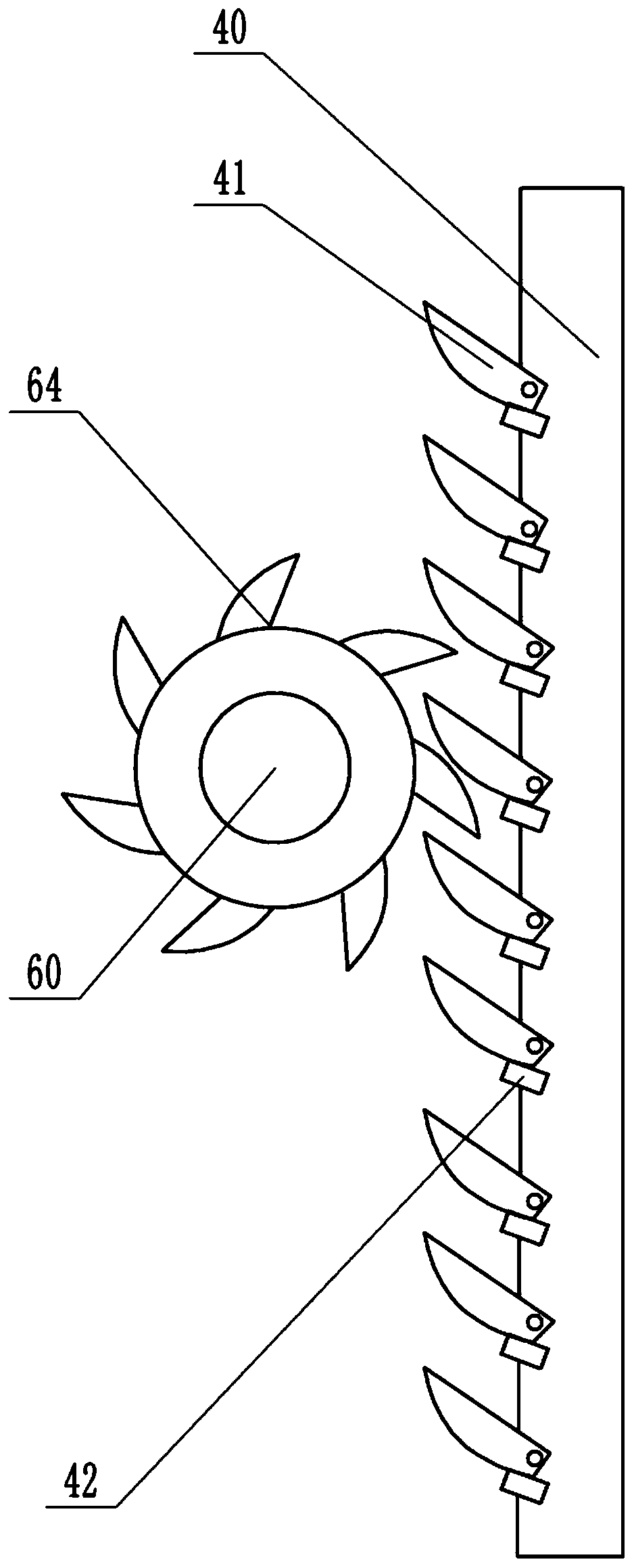

[0020] Instructions attached figure 1 The reference signs in include: frame 10, hydraulic cylinder 11, mounting seat 20, cutting knife 21, pull cord 30, mounting bar 40, claw 41, block 42, workbench 50, cutting groove 51, slide rail 52 , Rotating shaft 60, paper feed roller 61, unwinding roller 62, paper 63, ratchet 64, transmission plate 70, rack 71, collection tank 80, support plate 81, spring 82, transmission shaft 90, gear 91.

[0021] like figure 1 As shown, the paper cutter includes a paper feeding mechanism, a cutting mechanism and a collecting mechanism for collecting the cut paper 63 . The cutting mechanism includes a workbench 50, a frame 10, a mounting seat 20 and a power unit installed on the frame 10. In this embodiment, the power unit is a hydraulic cylinder 11, and the mounting seat 20 is fixed on the piston rod of the hydraulic cylinder 11. Mounting str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com