Molding tool of aluminum profile three-dimensional bent beam and process

A technology for forming tooling and aluminum profiles, applied to beams, transportation and packaging, and long-strip structural members for load-bearing, etc., can solve problems such as lack of theory or experience, to ensure product quality, avoid welding joints, and improve production Effects on efficiency and yield quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

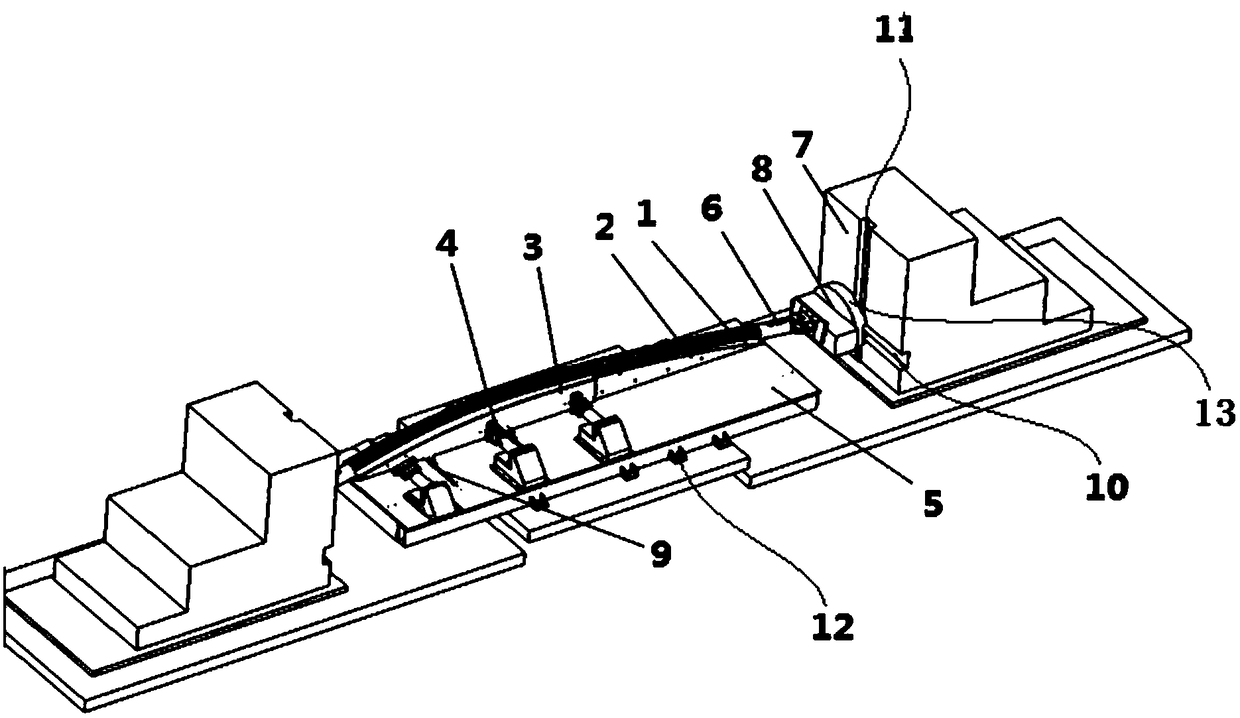

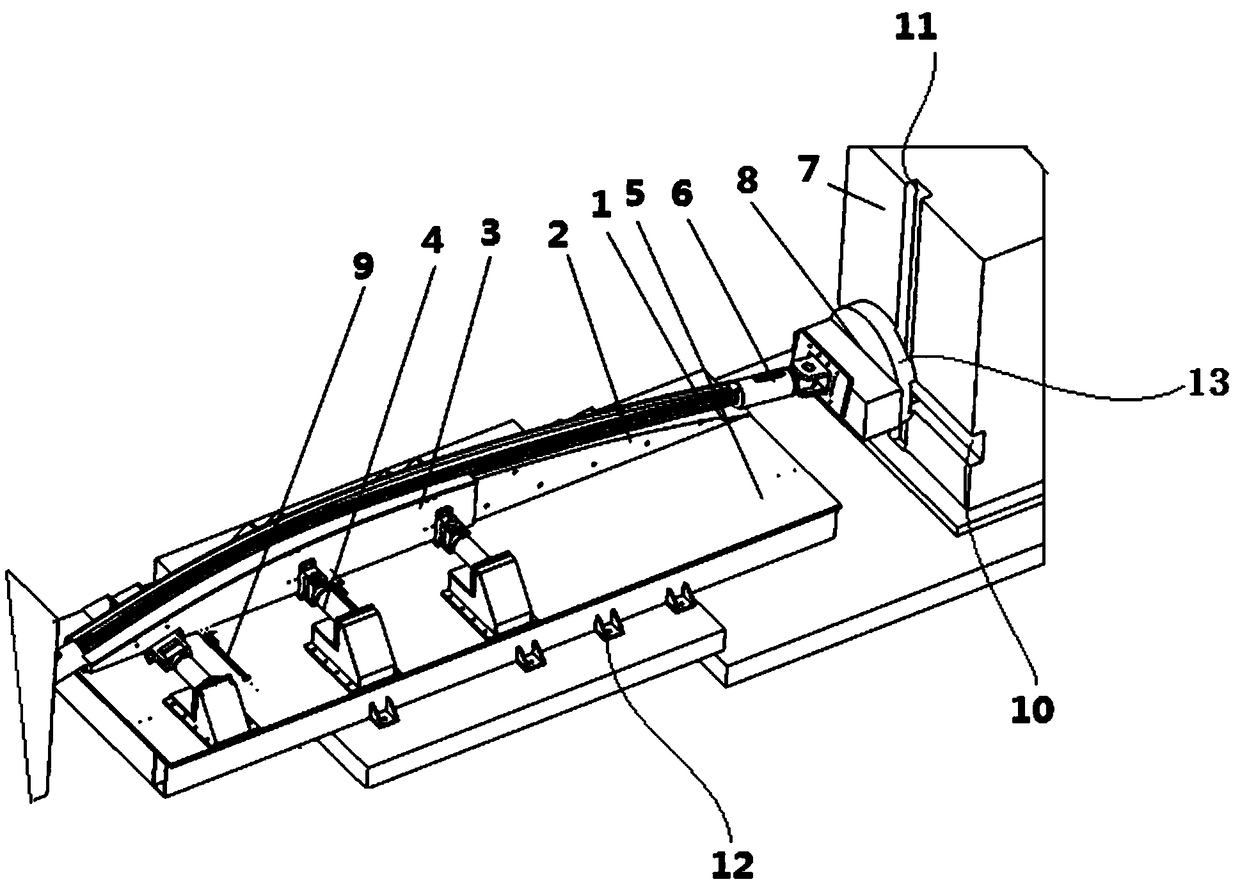

[0039] see Figure 1-2 shown;

[0040] The forming tooling of the aluminum profile three-dimensional curved beam of the present invention mainly includes:

[0041] Tooling installation platform 5;

[0042] The die 2 is fixed on the tooling installation platform 5;

[0043] The punch 3 is movably connected to the tooling installation platform 5;

[0044] The stretching assembly consists of two groups, which are symmetrically arranged at both ends of the tooling through the tensioning assembly mounting table 7, and the two sets of stretching assemblies respectively fix the two ends of the workpiece 1;

[0045] The stretching assembly applies a stretching force and a torsional force to the workpiece 1;

[0046] During processing, the workpiece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com