A light-emitting device, packaging method, and projection system

A light-emitting device and packaging method technology, which is applied in the field of lighting and display, can solve the problems of debonding, large structural stress, and the addition ratio of high thermal conductivity fillers should not be too high, and achieve the effect of high packaging and high reliability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

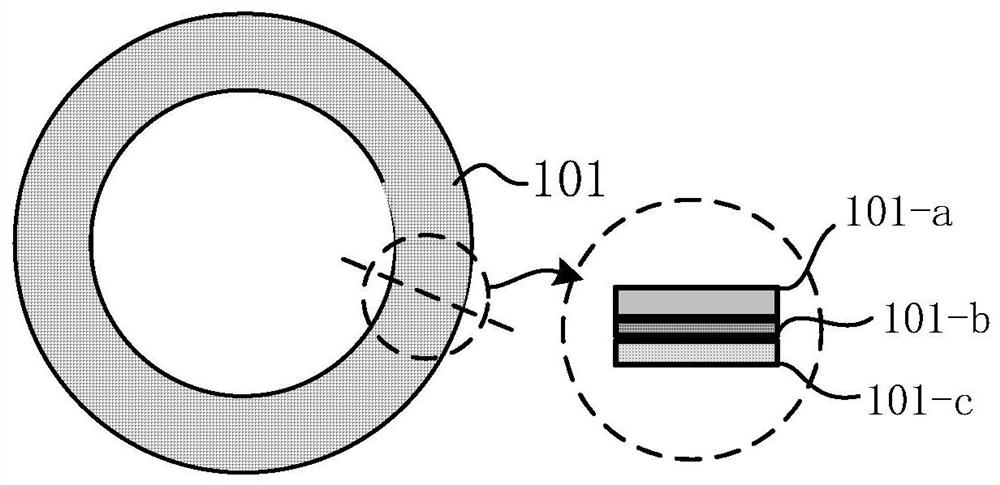

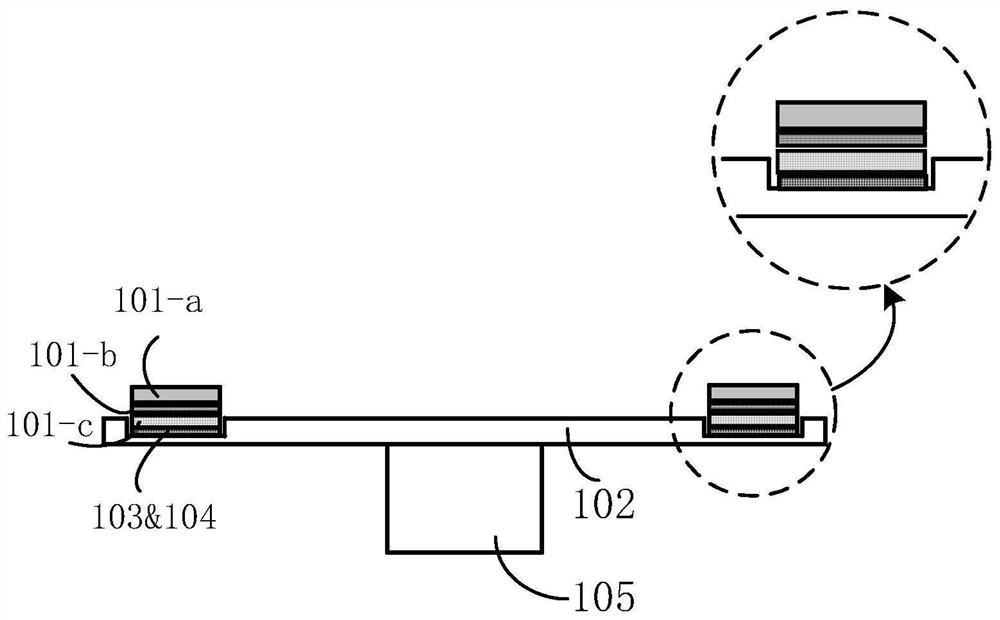

[0042] In this embodiment, a reflective layer and a light-emitting layer on the surface of the reflective layer are printed on one side of a ring-shaped ceramic substrate, such as figure 1 As shown, the ceramic wheel includes a light-emitting layer 101-a, a reflective layer 101-b, and a ceramic substrate 101-c; the whole constitutes the ceramic wheel 101.

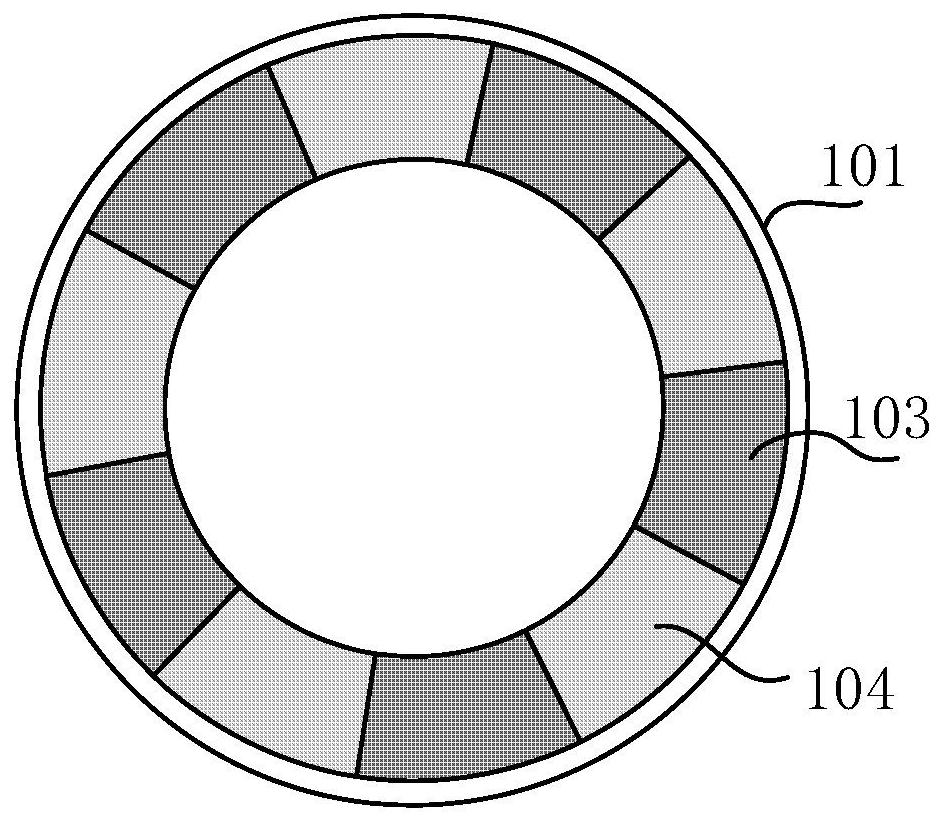

[0043] like figure 2 As shown, on the other side of the ceramic wheel, follow the figure 2 The distribution shown is schematic, that is, the area of high thermal conductivity glue 103 and the area of low thermal conductivity glue 104 are distributed at intervals along the circumferential direction, and high thermal conductivity glue 103 (thermal conductivity greater than 10w / (m k)) and strong adhesion are alternately coated respectively. Low thermal conductivity glue 104 (thermal conductivity less than 10w / (m k)), requires high thermal conductivity glue 103 area S 103 ≥S 104 , and 70%*S 104+103 ≥S 103 ≥50%*S 104...

Embodiment 2

[0047] In this embodiment, a reflective layer and a light-emitting layer on the surface of the reflective layer are printed on one side of a ring-shaped ceramic substrate, such as figure 1 As shown, the ceramic wheel includes a light-emitting layer 101-a, a reflective layer 101-b, and a ceramic substrate 101-c; the whole constitutes the ceramic wheel 101.

[0048] like Figure 4 As shown, on the other side of the ceramic wheel, follow the Figure 4 The distribution shown is schematic, that is, the area of the high thermal conductivity glue 103 and the area of the low thermal conductivity glue 104 are distributed in a concentric ring at intervals, and the high thermal conductivity glue 103 and the low thermal conductivity glue 104 with strong adhesion are respectively dispensed (or printed). Requires high thermal conductivity glue 103 area S 103 ≥S 104 , and 70%*S 104+103 ≥S 103 ≥50%*S 104+103 .

[0049] like Figure 5 As shown, the opposite surface of the high ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com