High-transmittance anti blue-ray lens, eyeglasses and device and manufacturing method thereof

A high transmittance, anti-blue light technology, applied in the fields of display and life medicine, can solve the problems of complex structure, and achieve the effect of simple structure, stable performance and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings.

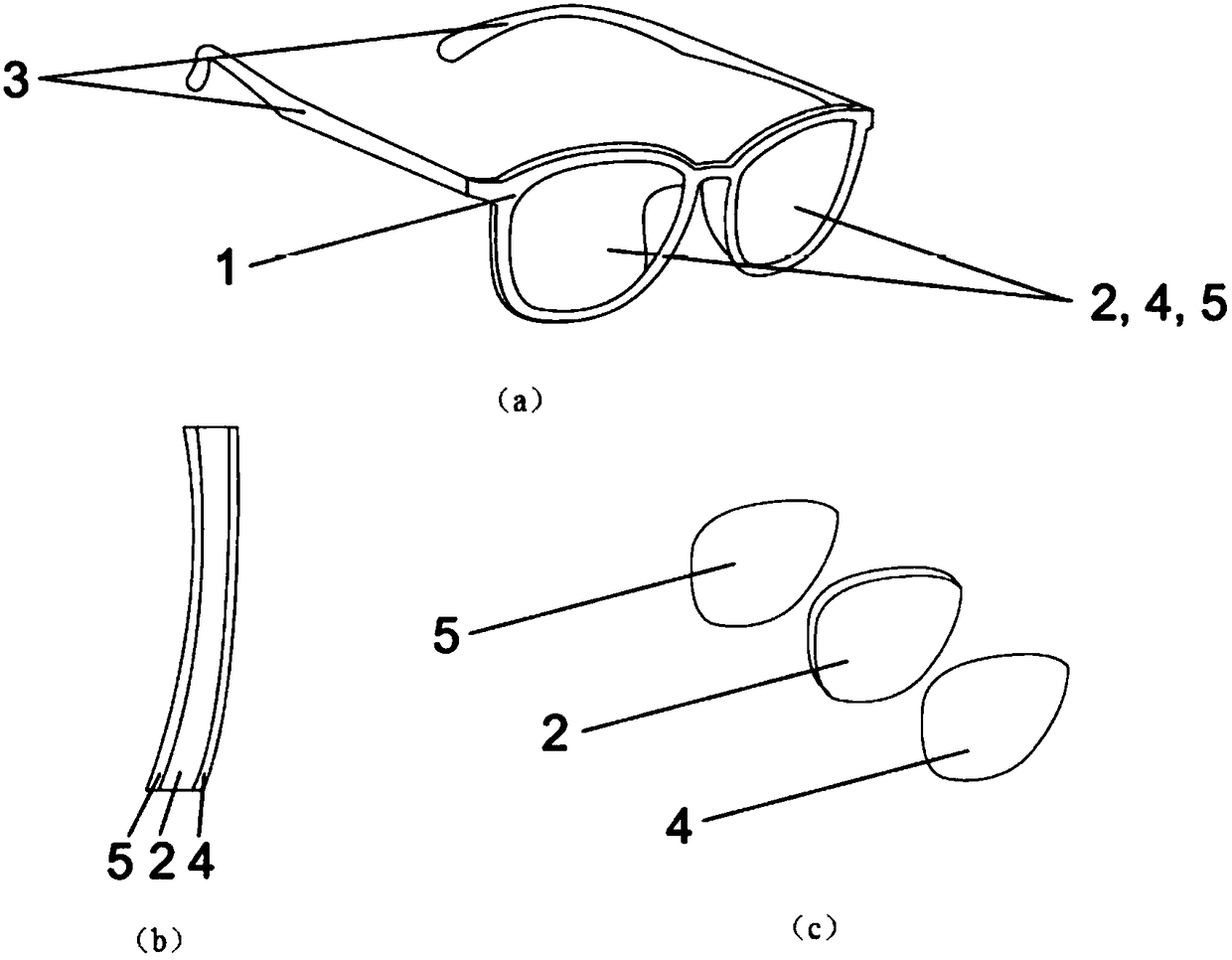

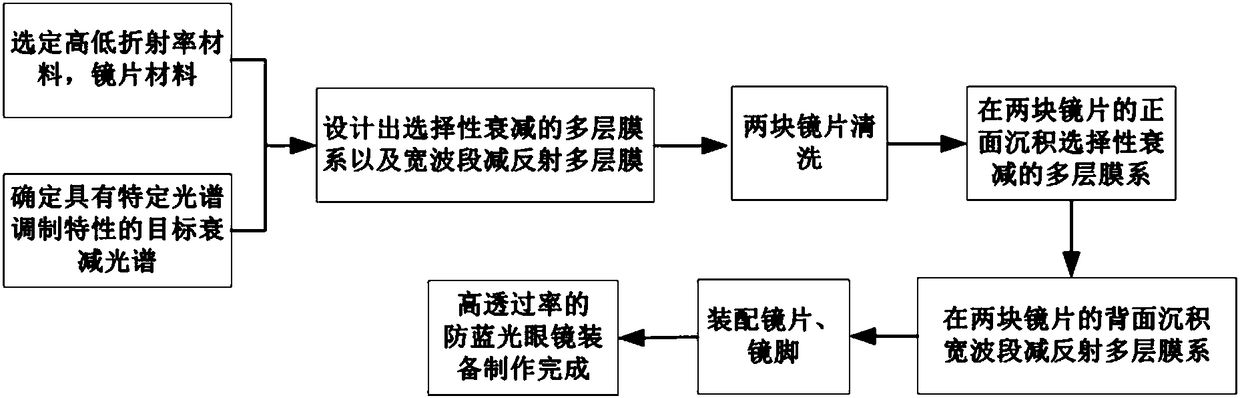

[0051] Such as figure 1 As shown in (a) to (c), a kind of anti-blue light glasses with high transmittance is composed of a frame 1, two lens bodies 2 fixed on the frame 1, and two mirror feet 3, which are respectively arranged on two A multilayer film stack 4 and a multilayer film stack 5 are formed on both sides of a lens body 2, wherein the multilayer film stack 4 is deposited on the fronts of the two lens bodies 2 (we define the side away from the human eye as the front side), and more The layer film stack 5 is deposited on the back of the two lens bodies 2, and the two lenses can be plano lenses, short-sighted lenses or long-sighted lenses.

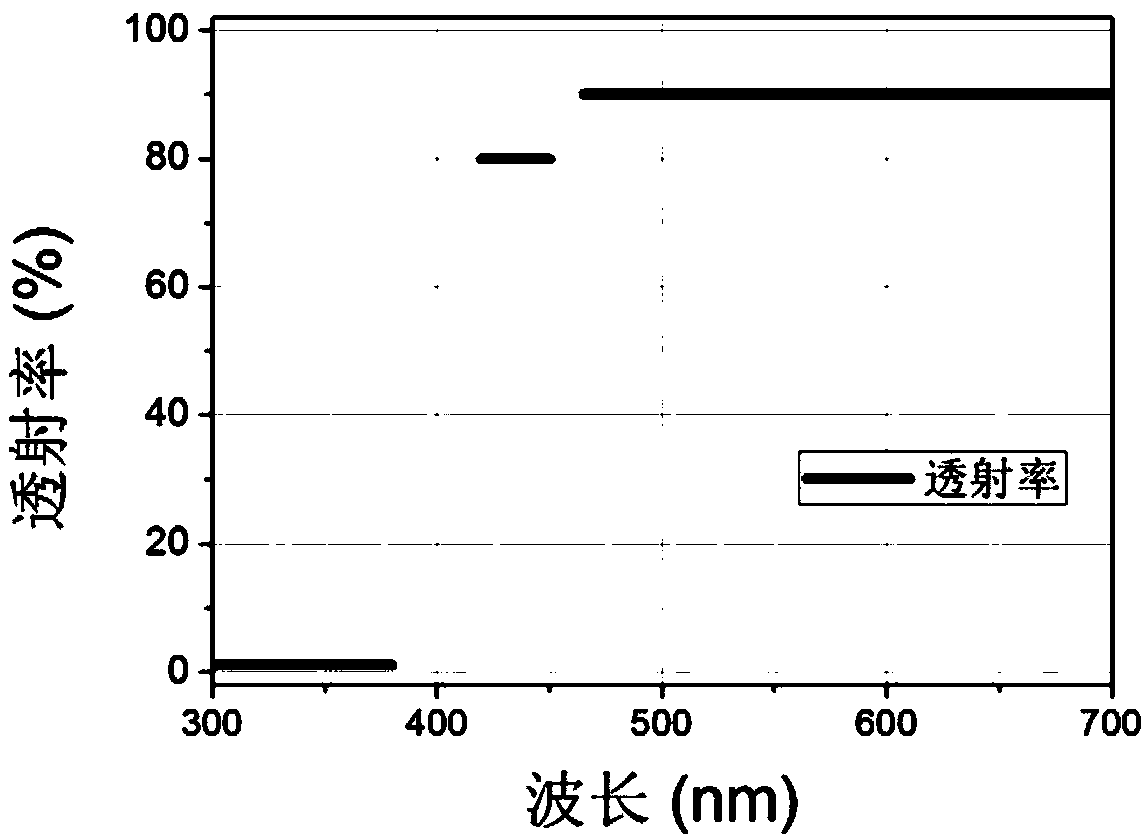

[0052] In the present invention, the optical characteristics realized by the special film system on the two lenses are obviously different from the general anti-blue light lens without the film system. At present, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com