A Method for Identifying Anisotropic Plastic Parameters of Materials Based on Spherical Indentation Morphology

A technology of anisotropy and plastic parameters, applied in the direction of testing material hardness, etc., can solve problems such as the influence of precision plastic forming of sheet metal, and achieve the effects of accurate and reliable experimental results, simple experimental process, and long preparation period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

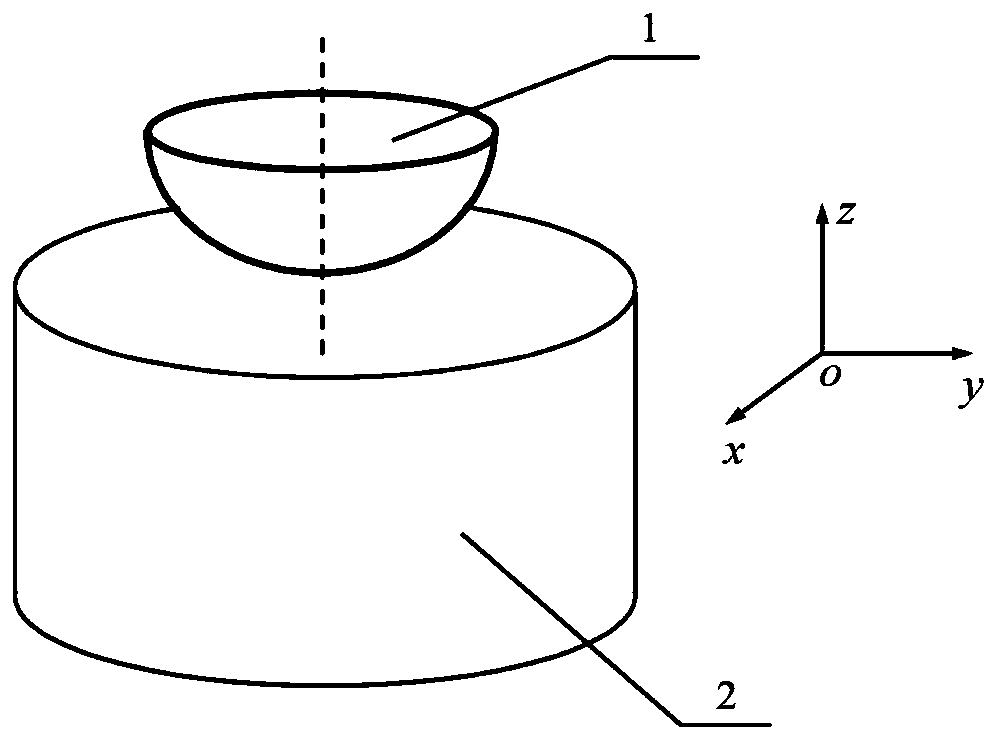

[0026] This embodiment is a method for identifying anisotropic plastic parameters of materials based on spherical indentation morphology.

[0027] refer to Figure 1 to Figure 5 , the specific implementation will be described below in conjunction with the selected silicon carbide fiber reinforced aluminum alloy SiC / Al6061 material as an engineering application example.

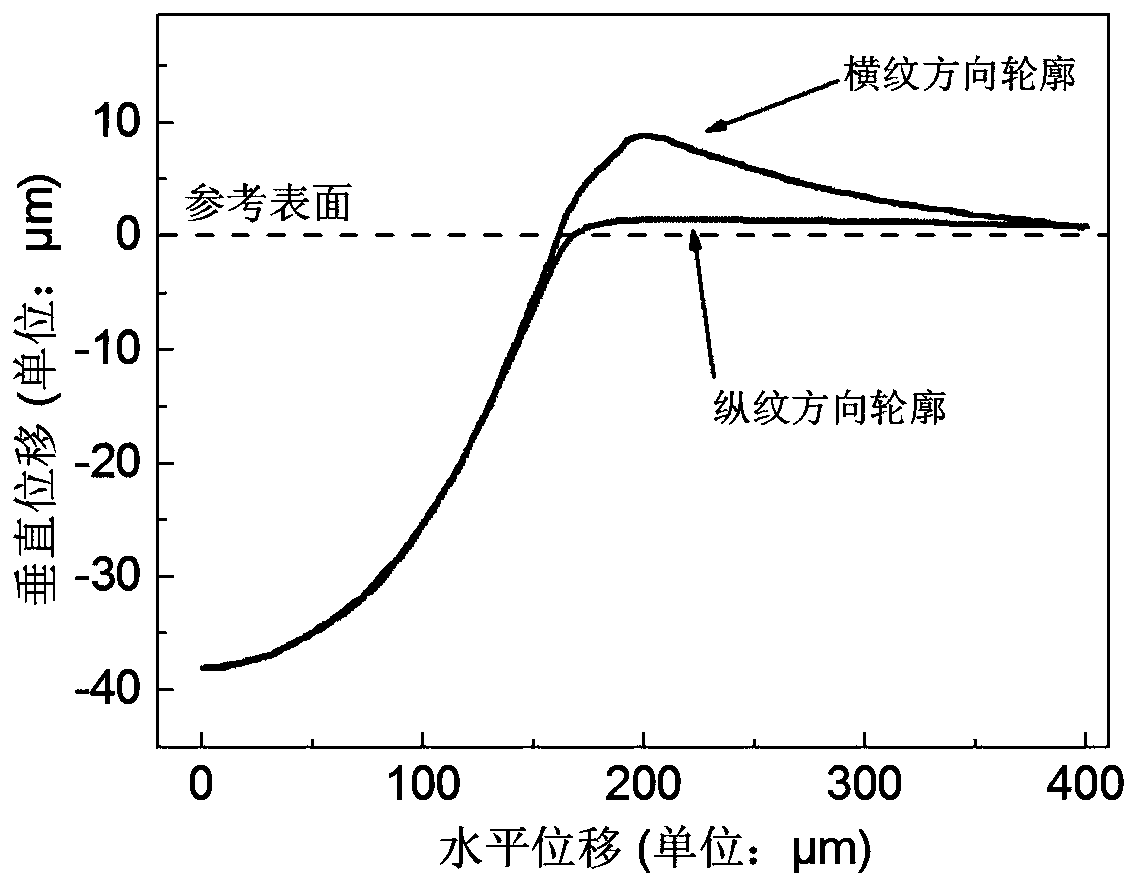

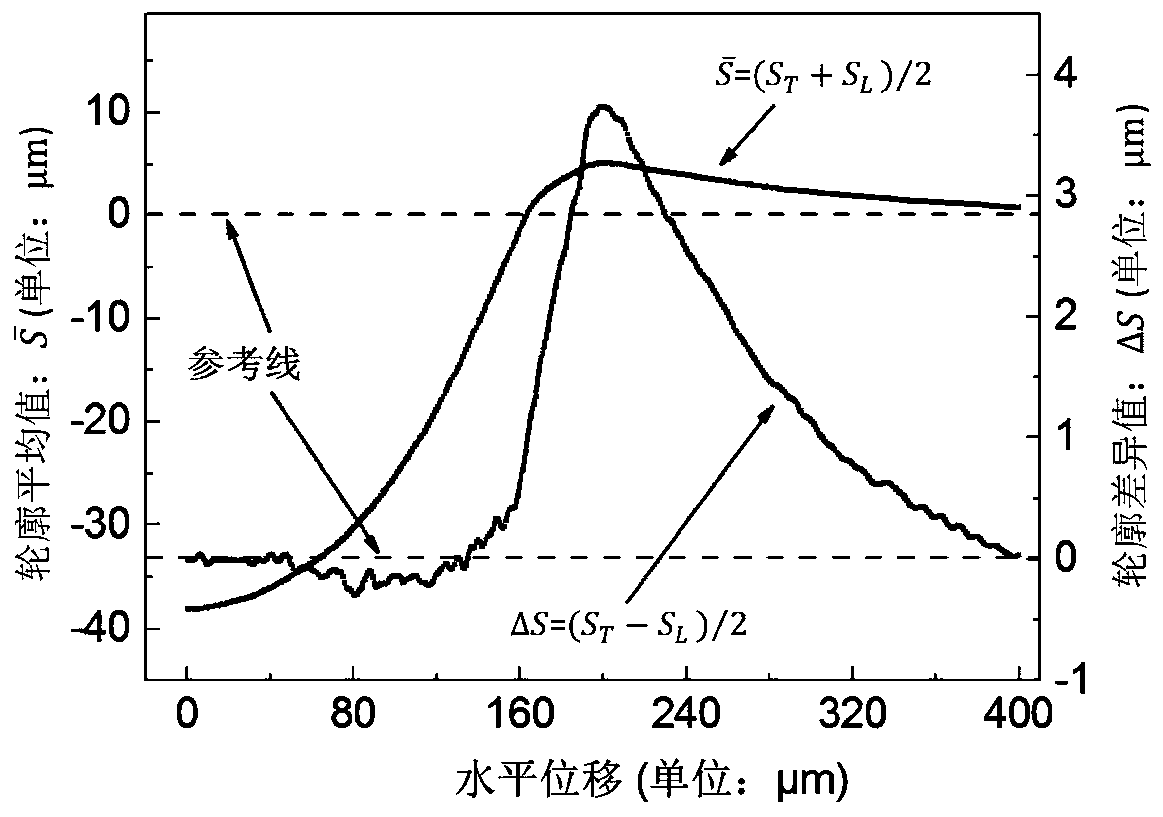

[0028] The first step is to conduct a spherical indentation experiment on the SiCw / A6061 material, and obtain a snapshot of the indentation profile along the two directions of the horizontal grain and the vertical grain through the confocal microscope test and Decompose these two snapshot vectors into an average amount and the difference ΔS exp two parts. Computing Experimental Weighted Profile Snapshots and the weight factor λ 1 and lambda 2 The values are all 1. Table 1 shows the uniaxial compression performance parameters of SiC / Al materials.

[0029] Table 1 Uniaxial mechanical properties of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com