Heat dissipation water tank structure of water cooling system

A technology of cooling water tank and water cooling system, which is applied to household refrigeration devices, lighting and heating equipment, cooling fluid circulation devices, etc. The effect of increasing convenience and practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the attached drawings are only for reference and illustration, and are not intended to limit the present invention.

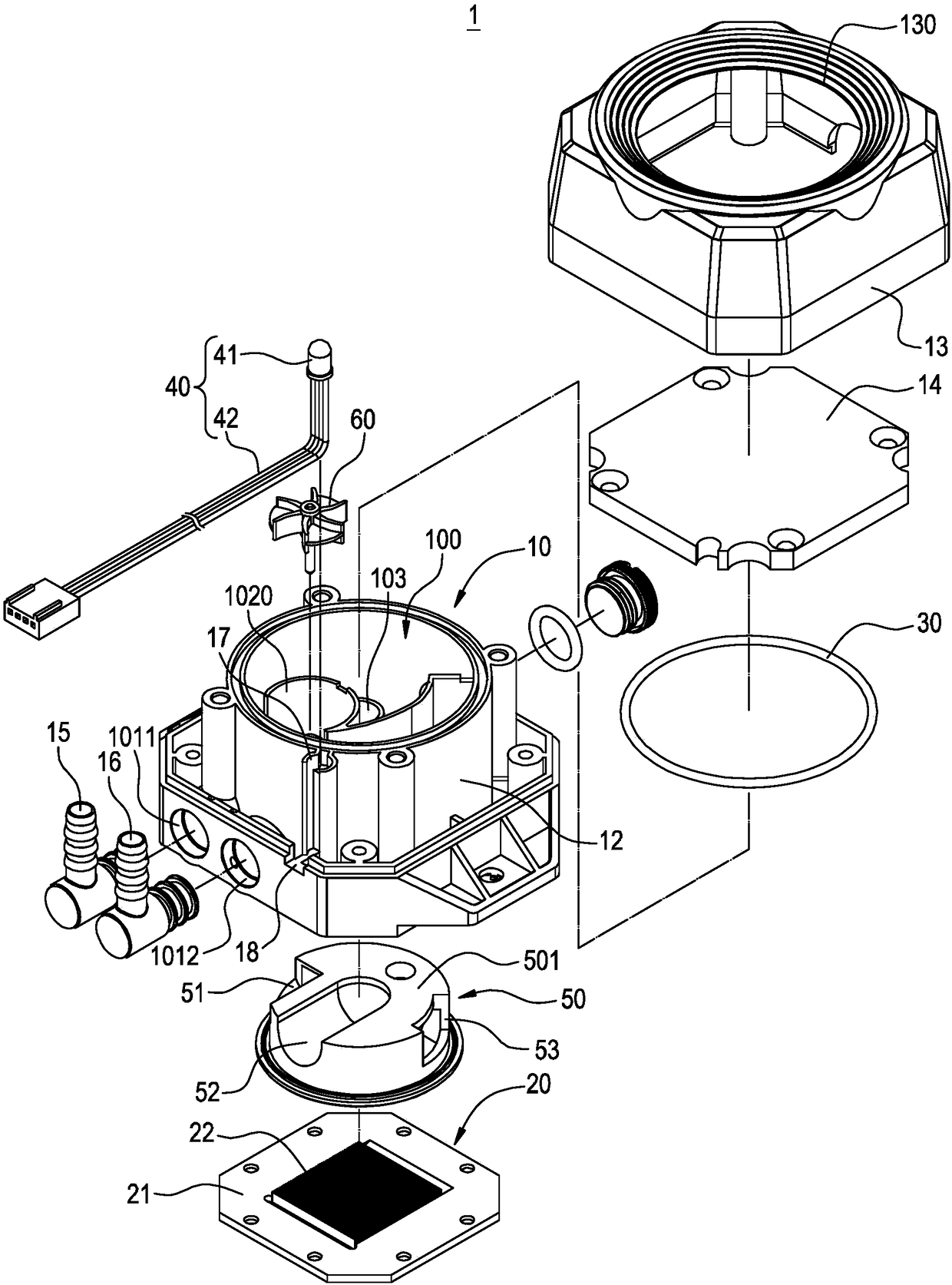

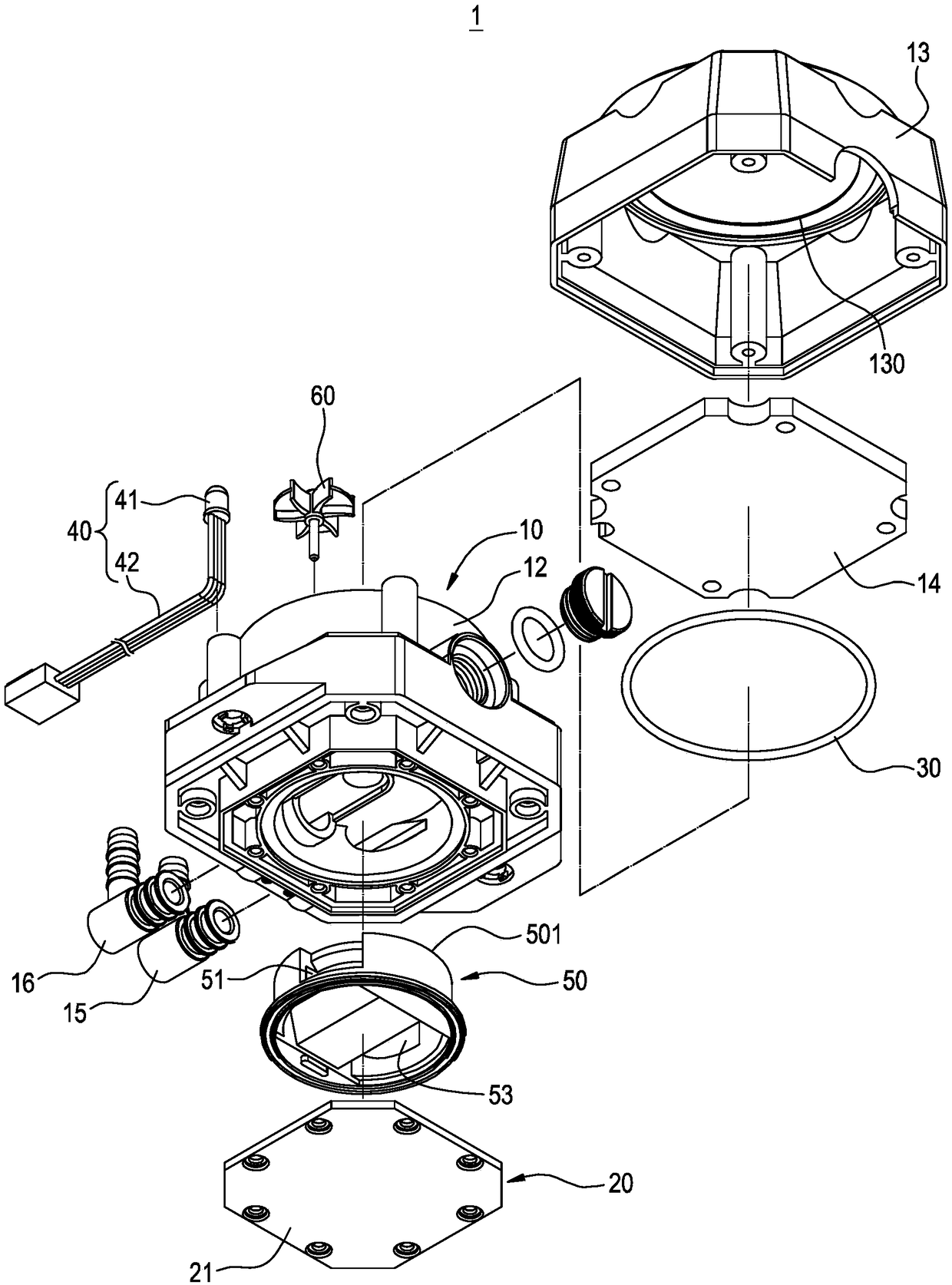

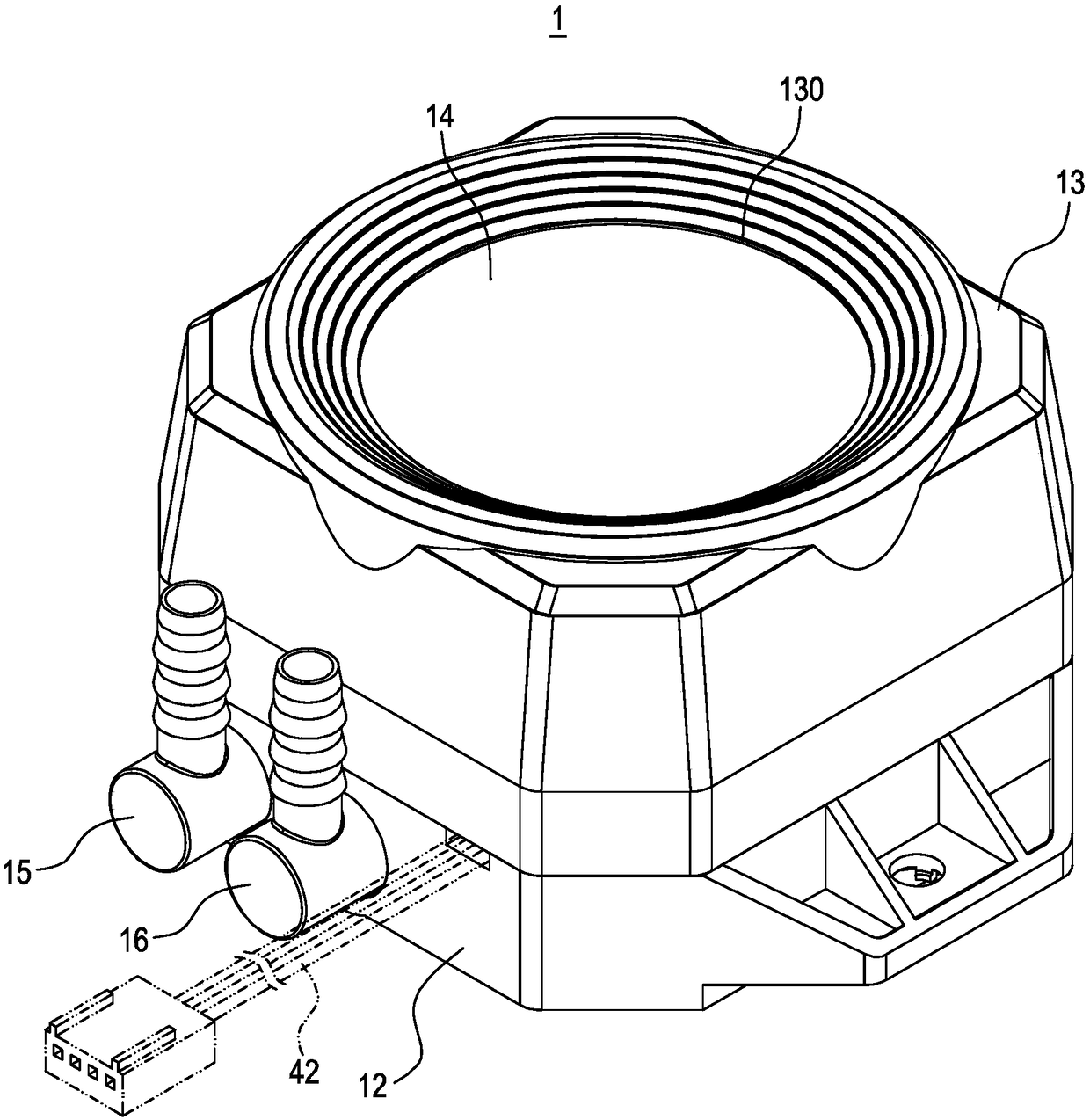

[0074] see Figure 1 to Figure 5 , which respectively show the three-dimensional exploded schematic diagram, the three-dimensional appearance schematic diagram, the three-dimensional appearance schematic diagram of the water distribution seat, and the one-side (longitudinal) cross-sectional view of the cooling water tank structure of the water cooling system of the present invention. The present invention provides a heat dissipation water tank structure 1 of a water cooling system, which includes a shell base 10 and a water cooling plate group 20 . The water-cooled plate assembly 20 is combined with an outer surface of the shell base 10 for adhering to a heat source and dissipating heat therefrom. The structure of the radiator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com