Columnar workpiece inner hole quenching device and equipment

A columnar workpiece and quenching device technology, applied in the field of mechanical processing, can solve the problems of low production efficiency, unfavorable quenching, high energy consumption, etc., achieve good quenching effect, reduce energy consumption, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

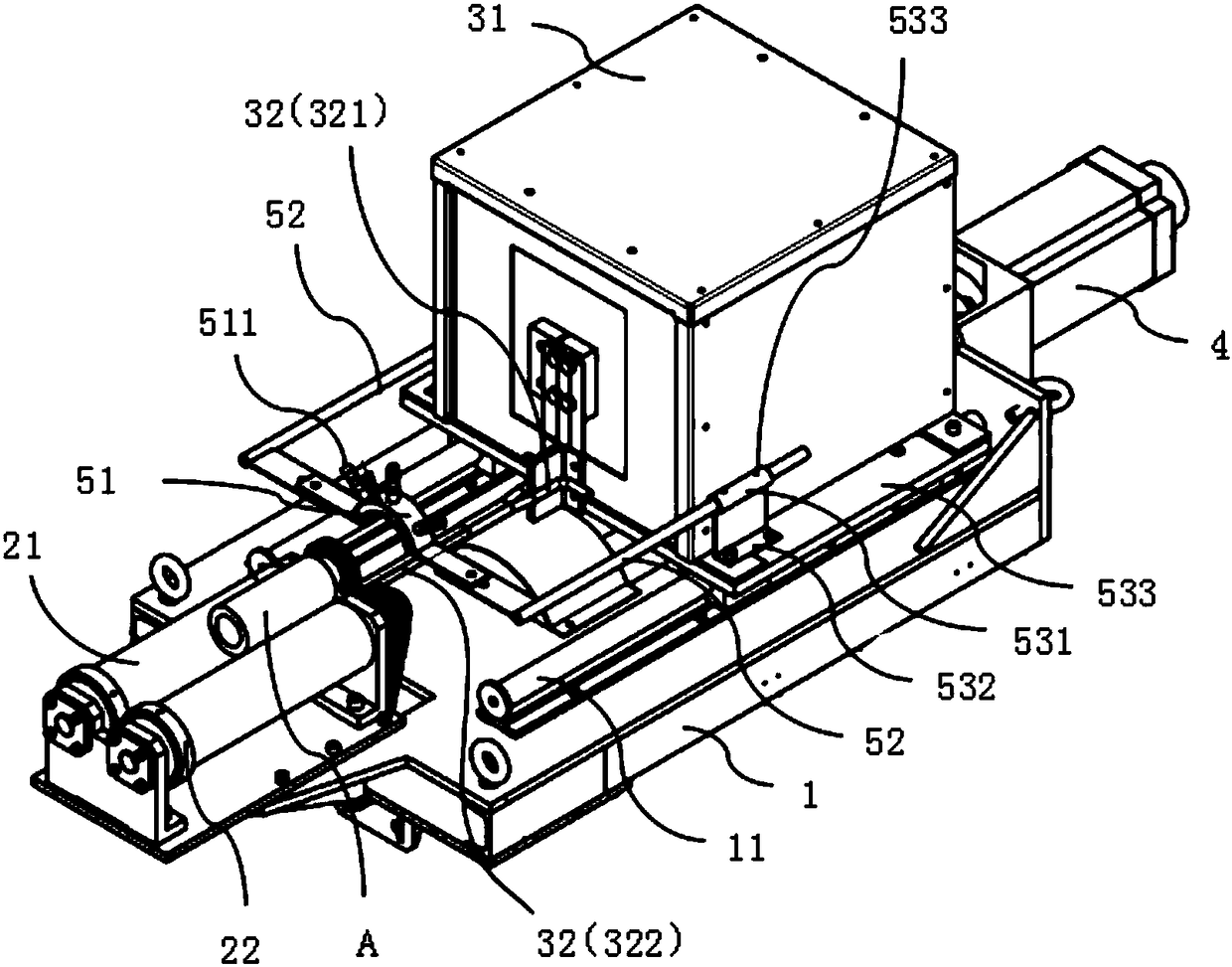

[0028] like figure 1 As shown, a columnar workpiece inner hole quenching device is provided, including a fixed frame 1 and a workpiece receiving part arranged on the fixed frame 1, a workpiece heating part, a workpiece cooling part and a displacement control part. The columnar workpiece A is located on the workpiece receiving part. The workpiece heating part can extend parallel to the inner hole of the cylindrical workpiece under the drive of the displacement control part for heating.

[0029] Specifically, the workpiece receiving part includes two parallel rollers 21 that can rotate in the same direction. The rollers 21 are metal rollers. The columnar workpiece A is arranged between the two rollers 21 and arranged parallel to the rollers. The gap between them is very small, which can ensure that the quenching device for the inner hole of the columnar workpiece can be adapted to the quenching process of columnar workpieces of various sizes, that is, when the outer circumferenc...

Embodiment 2

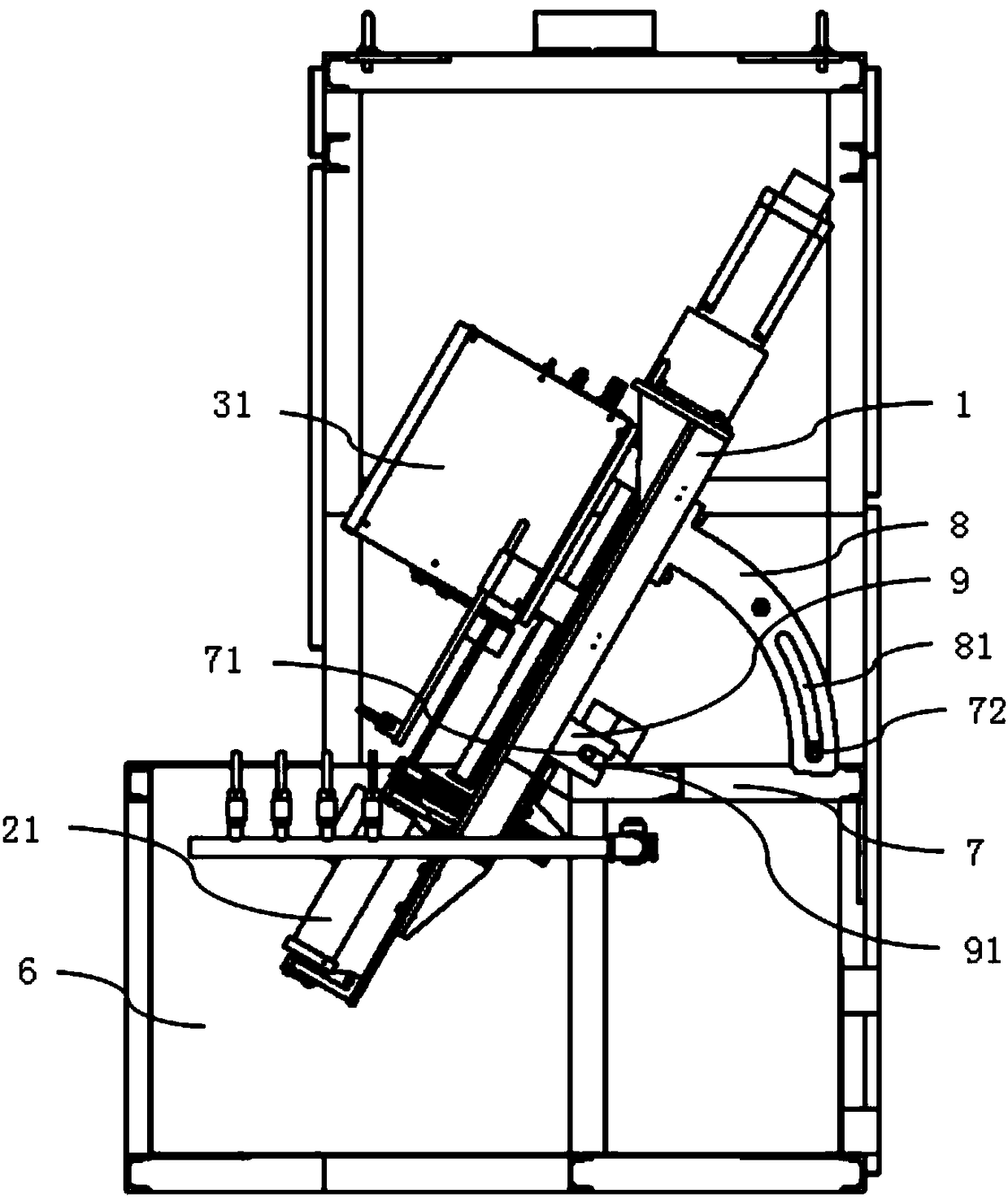

[0041] A cylindrical workpiece inner hole quenching equipment, such as figure 2 As shown, the cylindrical workpiece inner hole quenching device of Embodiment 1 is provided, and the cylindrical workpiece inner hole quenching device is arranged obliquely on the cylindrical workpiece inner hole quenching equipment, wherein the quenching transformer 31 is at the inclined top end, the roller 21 is at the inclined bottom end, and also provided There is a water tank 6 located below the quenching device of the inner hole of the cylindrical workpiece, and the cooling liquid passed into the heating part of the workpiece finally flows into the water tank 6 after passing through the inner hole wall of the workpiece.

[0042] There is also a spray pump (not shown) in the quenching equipment for the inner hole of the cylindrical workpiece. The spray pump is electrically connected to the cooling part of the workpiece. At the same time, a filter device (not shown) is provided in the water tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com