Bimaleimide composition and preparation method thereof

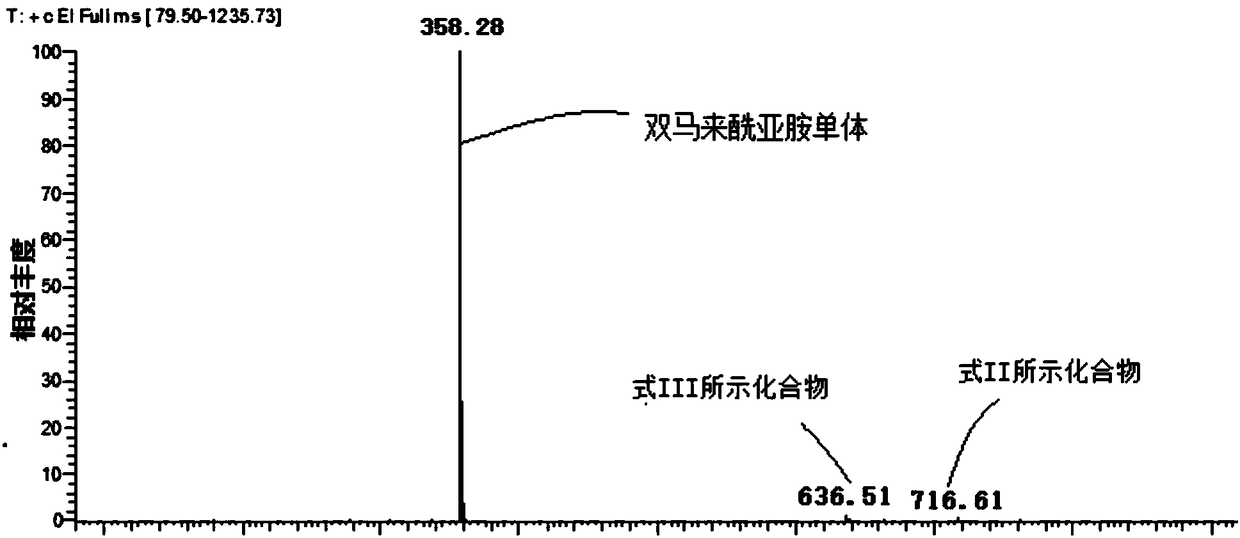

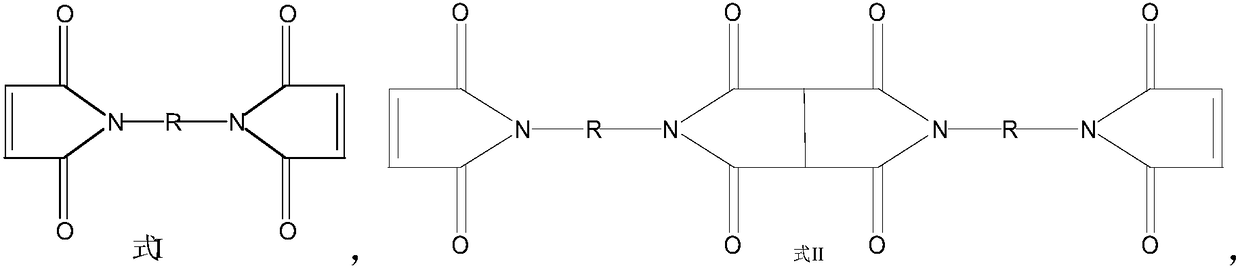

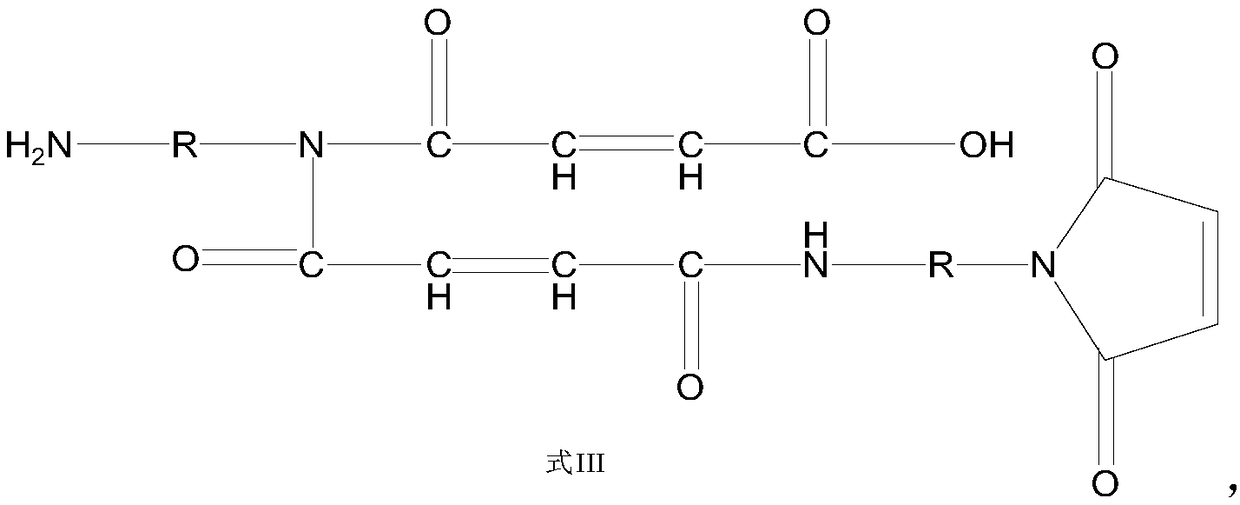

A technology of bismaleimide and composition, applied in the field of bismaleimide composition and its preparation, can solve problems such as product performance influence, achieve excellent performance, excellent heat resistance, high heat resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] This embodiment prepares the bismaleimide composition through the following steps

[0064] (1) Dissolve diaminodiphenylmethane in a solvent, drop it into a solvent containing maleic anhydride at 20°C within 3 hours, wherein the molar ratio of maleic anhydride to diaminodiphenylmethane is 2 : 1, solvent is toluene, adds p-toluenesulfonic acid, wherein the weight ratio of p-toluenesulfonic acid and toluene is 0.25:1, is heated to reflux reaction 3h, in the reaction process, the water in the system is continuously separated with a water separator, Then cool down to 80°C, add water to the system, let it stand, filter out the insoluble matter obtained by the reaction, wherein the weight ratio of water to solvent is 1:1, stir and raise the temperature to 100°C, let it stand for stratification, and drain the lower layer of water, Collect the upper layer solution.

[0065] (2) Dissolve the insoluble matter obtained in step (1) and the upper layer solution in toluene, heat to 9...

Embodiment 2

[0069] This embodiment prepares the bismaleimide composition through the following steps

[0070] (1) Dissolve diaminodiphenylmethane in a solvent, drop it into a solvent containing maleic anhydride at 25° C. within 1 hour, wherein the reaction molar ratio of maleic anhydride to diaminodiphenylmethane is 1.5: 1, the solvent is toluene and dimethylformamide (the weight ratio of toluene and dimethylformamide is 1:1), add p-toluenesulfonic acid, wherein the weight ratio of p-toluenesulfonic acid and solvent is 0.5:1, heat After reflux for 1 hour, the water in the system was continuously separated with a water separator during the reaction, and then the temperature was lowered to 70°C, water was added to the system, and the insoluble matter obtained by the reaction was filtered off. The weight of water and solvent The ratio is 0.1:1. Stir and heat up to 80°C and let stand to separate layers. The water in the lower layer is drained and the upper layer solution is collected.

[007...

Embodiment 3

[0073] This embodiment prepares the bismaleimide composition through the following steps

[0074] (1) Dissolve diaminodiphenylmethane in a solvent, drop it into a solvent containing maleic anhydride at 10°C within 5 hours, wherein the reaction molar ratio of maleic anhydride to diaminodiphenylmethane is 3 :1, the solvent is toluene and acetone (the weight ratio of toluene and acetone is 1:0.5), adding p-toluenesulfonic acid, wherein the weight ratio of p-toluenesulfonic acid and solvent is 0.01:1, heated to reflux for 6h, the reaction process Use a water separator to continuously separate the water in the system, then cool down to 70°C, add water to the system, let it stand, filter out the insoluble matter obtained by the reaction, wherein the weight ratio of water to solvent is 2:1, stir Raise the temperature to 105°C and let stand to separate layers, drain the water from the lower layer, and collect the upper layer solution.

[0075] (2) Dissolve the insoluble matter obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com