Rigid polyurethane foam plastic and preparation method thereof

A rigid foam plastic and polyurethane technology, applied in the field of thermal insulation materials, can solve the problems such as the inability to use in large quantities downstream, the high thermal conductivity of foam, and the reduction of the amount of foam used, and achieve good fluidity, low thermal conductivity, and high thermal conductivity. The effect of improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

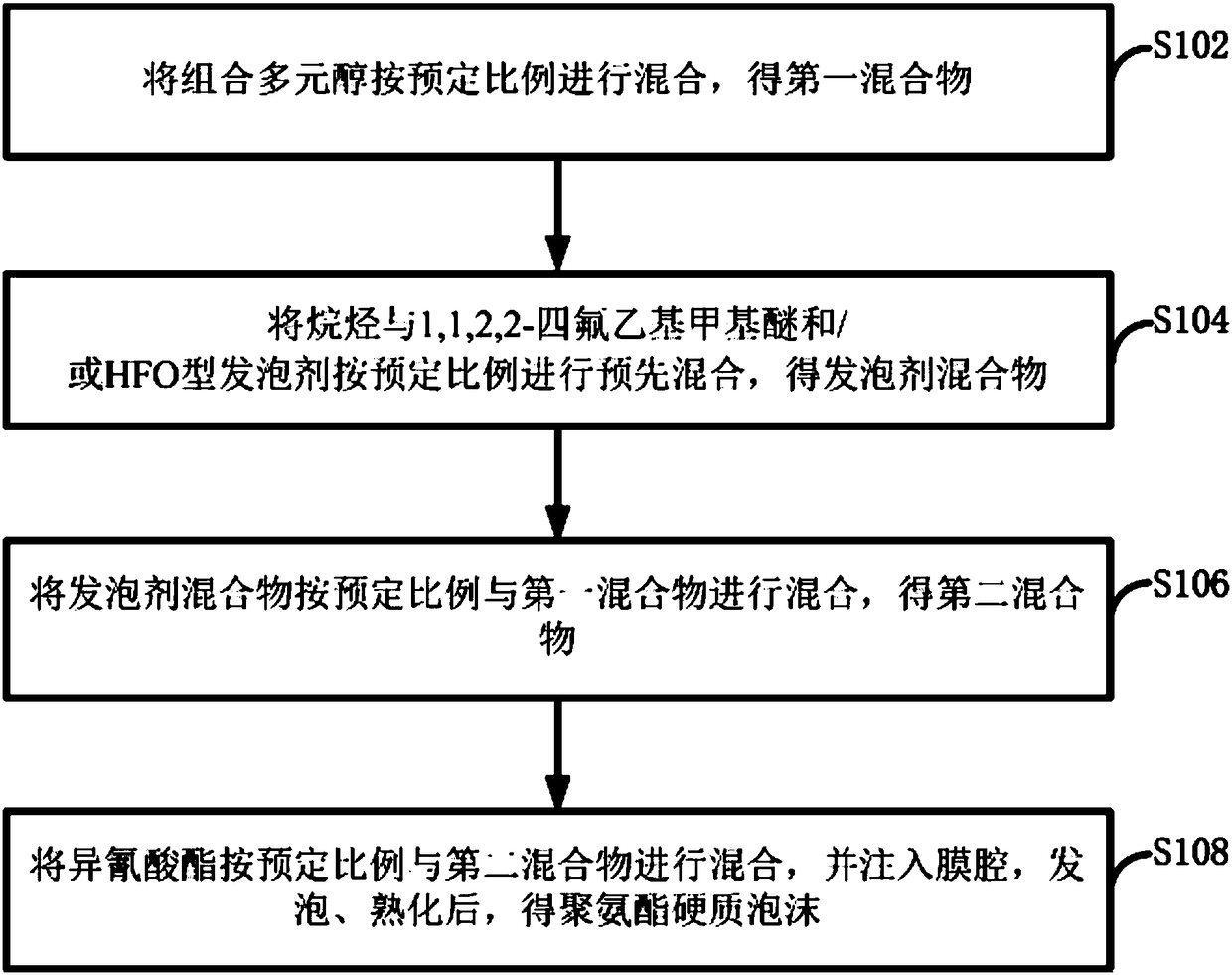

[0048] figure 1 It is a flow chart of the preparation method of polyurethane rigid foam according to one embodiment of the present invention. The present invention also provides a kind of preparation method of polyurethane rigid foam, and this method specifically comprises:

[0049] S102, mixing the combined polyols in a predetermined ratio to obtain a first mixture;

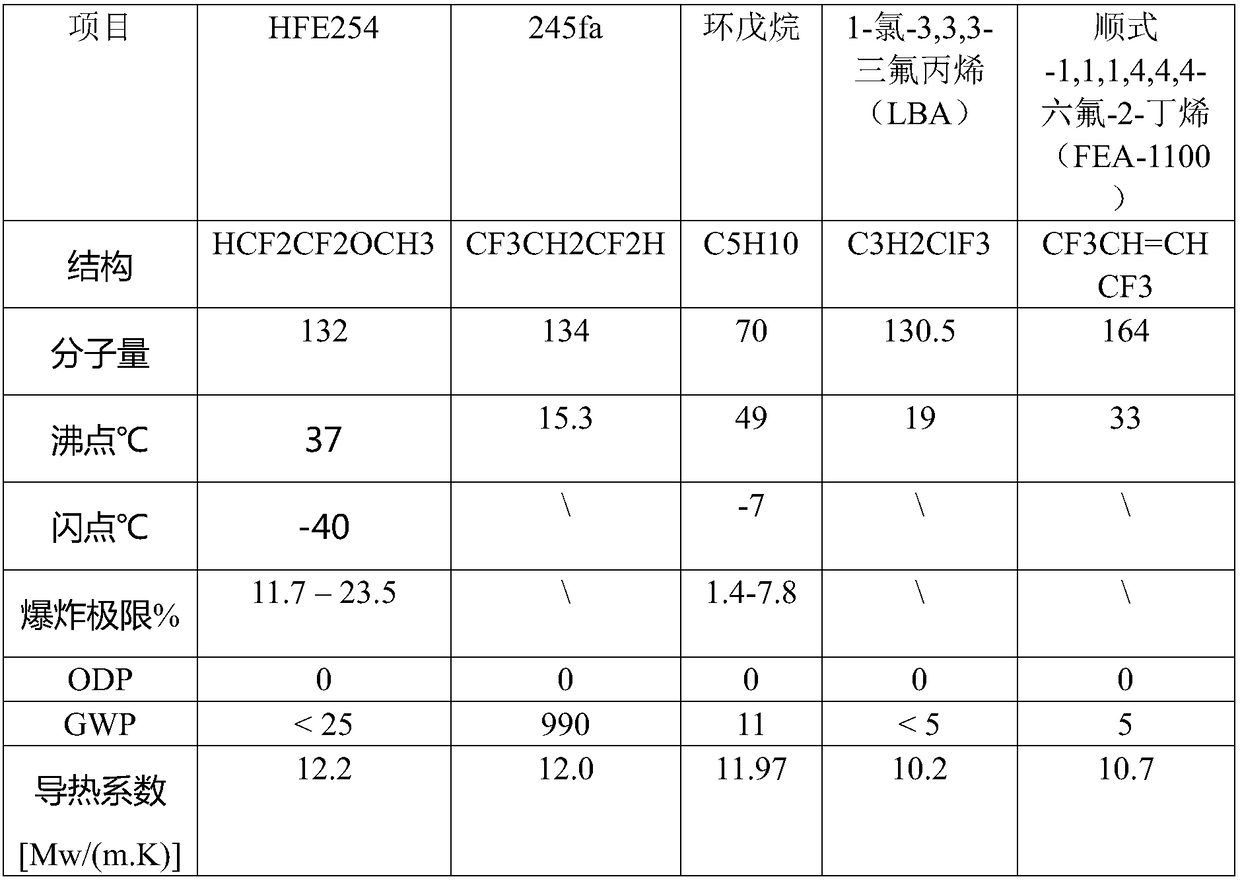

[0050] S104, pre-mixing alkanes with 1,1,2,2-tetrafluoroethyl methyl ether and / or HFO blowing agent in a predetermined ratio to obtain a blowing agent mixture;

[0051] S106, mixing the foaming agent mixture with the first mixture in a predetermined ratio to obtain a second mixture;

[0052] S108, mixing the isocyanate with the second mixture according to a predetermined ratio, injecting the isocyanate into the film cavity, foaming and curing, to obtain rigid polyurethane foam.

[0053]The combined polyol is stirred for 2-3 hours at a temperature of 20-25°C, that is, polyether polyol A, polyether polyol B, po...

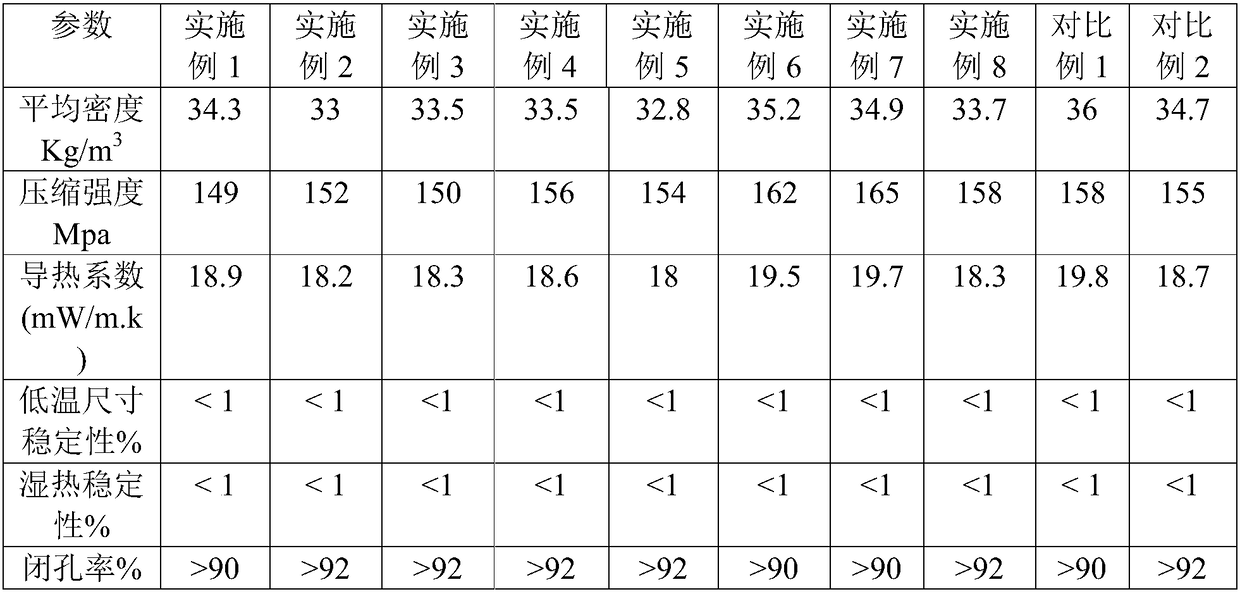

Embodiment 1

[0063] The parts by mass of each raw material in Example 1: polyol: 100 parts, cyclopentane: 10 parts, HFE254: 10 parts, isocyanate: 145 parts.

[0064] Polyurethane rigid foam preparation method is specifically as follows:

[0065] (1) Mix the combined polyols at 20-25°C for 2-3 hours to make a pre-whitening material;

[0066] (2) Mixing cyclopentane and HFE245 at a temperature of 20-25° C. and a mixing pressure of 2-3 bar for 2-3 hours to prepare a blowing agent mixture;

[0067] (3) mixing the foaming agent mixture and the pre-white material at a temperature of 20°C and a mixing pressure of 2-3 bar for 2-3 hours to prepare a second mixture;

[0068] (4) Mix the second mixture and isocyanate at 20-25°C under a pressure of 120-130 bar, inject into a preheated 40-50°C mold cavity, foam and mature;

[0069] (5) Demoulding the cooled foam to test related properties.

Embodiment 2

[0071] The parts by mass of each raw material in Example 2: polyol: 100 parts, cyclopentane: 10 parts, HFE254: 10 parts, LBA: 6 parts, isocyanate: 145 parts. Referring to Example 1 for the preparation method of polyurethane rigid foam, cyclopentane and HFE245 in step (2) were replaced with cyclopentane, HFE245 and LBA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com