Solvent-free one-component polyurethane grouting material and preparation method thereof

A grouting material and one-component technology, which is applied in the field of solvent-free one-component polyurethane grouting material and its preparation, can solve the problems of environmental pollution, inability to quickly block water, solvent-based polyurethane grouting material is not environmentally friendly, and achieve hydrophilicity Good performance, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

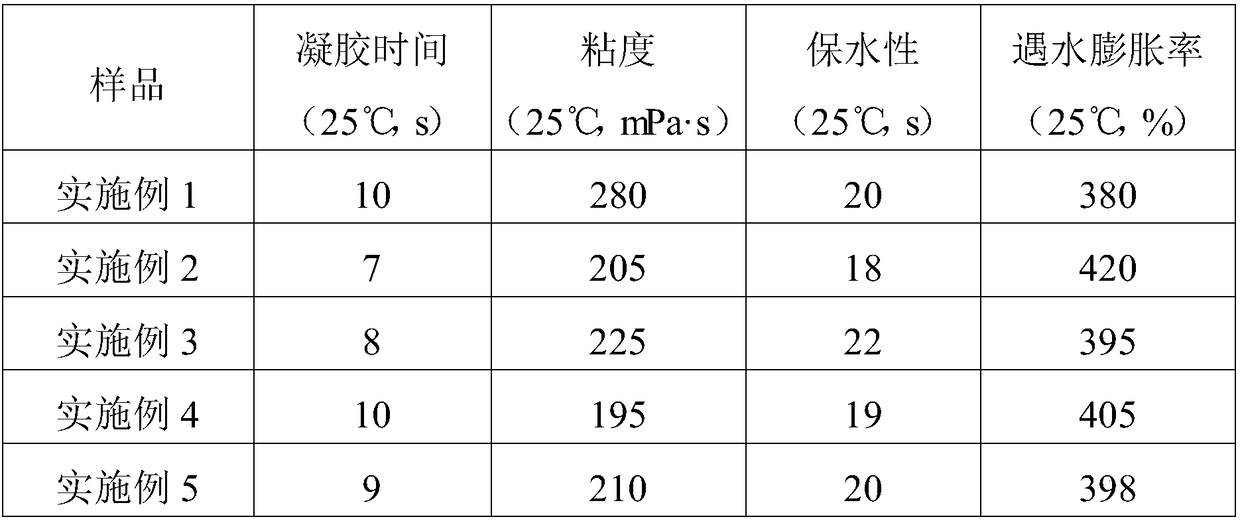

Examples

Embodiment 1

[0034] A solvent-free one-component polyurethane grouting material, which is prepared by the following preparation method:

[0035] (1) Put 100g of hydrophilic polyether polyol DJ-1 into the reaction kettle, raise the temperature to 100°C, stir, vacuum dehydrate and degas for 3 hours, cool down to 50°C, then add 45g of toluene diisocyanate TDI-80, in At a reaction temperature of 80°C, the reaction polymerization was carried out for 3 hours to obtain 145 polyurethane prepolymers; among them, the functionality of the hydrophilic polyether polyol DJ-1 was 3, and the number average molecular weight was 12000; the -NCO of the polyurethane prepolymer The content is 14.26%;

[0036] (2) Cool down to 50°C, fully stir and mix the polyurethane prepolymer obtained in step (1) with 3g water-soluble silicone oil AK8805, 0.75g bismorpholino diethyl ether and 15g diethyl phthalate, namely have to.

Embodiment 2

[0038] A solvent-free one-component polyurethane grouting material, which is prepared by the following preparation method:

[0039] (1) Put 100g of hydrophilic polyether polyol DJ-2 into the reaction kettle, raise the temperature to 102°C, stir, vacuum dehydrate and degas for 3 hours, cool down to 52°C, and then add 100g of diphenylmethane diisocyanate MDI- 50, at a reaction temperature of 82°C, react and polymerize for 3 hours to obtain 200 g of polyurethane prepolymer; among them, the functionality of the hydrophilic polyether polyol DJ-2 is 2, and the number average molecular weight is 8000; the polyurethane prepolymer The -NCO content is 16.28%;

[0040] (2) Lower the temperature to 52°C, fully stir and mix the polyurethane prepolymer obtained in step (1) with 4g of water-soluble silicone oil 8407, 2g of N-ethylmorpholine and 15g of dioctyl phthalate.

Embodiment 3

[0042] A solvent-free one-component polyurethane grouting material, which is prepared by the following preparation method:

[0043] (1) Put 100g of hydrophilic polyether polyol DJ-3 into the reactor, raise the temperature to 98°C, stir, vacuum dehydrate and degas for 3 hours, cool down to 48°C, then add 25g of toluene diisocyanate TDI-80 and 50g Diphenylmethane diisocyanate MDI-50, at a reaction temperature of 78 ° C, reacted and polymerized for 3 hours to obtain 175 g of polyurethane prepolymer; among them, the functionality of the hydrophilic polyether polyol DJ-3 was 3, and the number average The molecular weight is 10000; the -NCO content of the polyurethane prepolymer is 15.78%;

[0044] (2) Cool down to 48°C, mix the polyurethane prepolymer obtained in step (1) with 0.75g water-soluble silicone oil 8407, 0.75g water-soluble silicone oil AK8805, 1.2g N-ethylmorpholine, 6g diethyl phthalate and 6g of dioctyl phthalate was fully stirred and mixed evenly to obtain the product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com