Continuous preparation method of black phosphorus

A black phosphorus and mineralizer technology, applied in the field of phosphorus chemical industry, can solve the problems of difficult industrial continuous production, poor crystallinity of black phosphorus, unfavorable large-scale production, etc., and achieve full utilization, low cost and mild conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

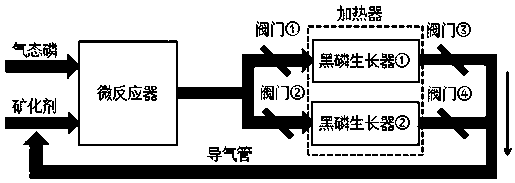

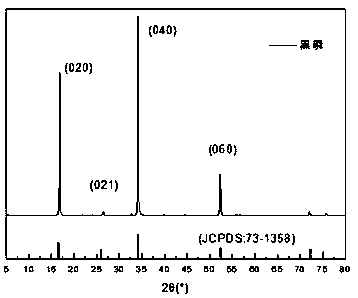

[0025] The gaseous yellow phosphorus and mineralizers (Sn and SnI 4 Mixed according to the mass ratio of 1:1) slowly pass into the microreactor, the temperature inside the microreactor is 550 ° C, after making it fully mixed and reacted in the microreactor, the obtained gaseous product is further passed into the black phosphorus In the grower, the temperature in the black phosphorus grower is 200°C. Black phosphorus grows in the black phosphorus grower. At the same time, the mineralizer is separated from the black phosphorus in gaseous form and mixed with the initial mineralizer to continue to use. After a period of reaction , open the black phosphorus grower, you can get high-purity black phosphorus, the purity is greater than 99.9%, the obtained black phosphorus physical map and XRD pattern are as follows figure 2 with image 3 shown by image 3 It can be seen that the four obvious characteristic peaks of black phosphorus are at 17.03°, 26.61°, 34.32°, and 52.42° respecti...

Embodiment 2

[0027] Gaseous yellow phosphorus and mineralizers (Bi, PbI 2 , BiI 3 According to the mass ratio of 1:1:2) slowly pass into the microreactor, the temperature in the microreactor is 570 ° C, after it is fully mixed and reacted in the microreactor, the gaseous product obtained is further passed into the In the black phosphorus grower, the temperature inside the black phosphorus grower is 250°C, the black phosphorus grows in the black phosphorus grower, and the mineralizer is separated from the black phosphorus in gaseous form and mixed with the initial mineralizer to continue to use, reacting for a period of time After a period of time, turn on the black phosphorus grower to obtain high-purity black phosphorus with a purity greater than 99.9%. The XRD pattern of the black phosphorus that present embodiment prepares is as follows Figure 4 As shown, it can be seen from the figure that the four obvious characteristic peaks of black phosphorus are at 17.05°, 26.40°, 34.23°, and ...

Embodiment 3

[0029] Gaseous yellow phosphorus and mineralizers (In and NH 4 I is mixed according to the mass ratio of 3:1) slowly into the microreactor, the temperature in the microreactor is 600 °C, after it is fully mixed and reacted in the microreactor, the gaseous product obtained is further passed into the black In the phosphorus grower, the temperature in the black phosphorus grower is 300°C, and the black phosphorus grows in the black phosphorus grower. At the same time, the mineralizer is separated from the black phosphorus in gaseous form and mixed with the initial mineralizer to continue to use, and react for a period of time Finally, turn on the black phosphorus grower to obtain high-purity black phosphorus with a purity greater than 99.9%. The XRD pattern of the black phosphorus that present embodiment prepares is as follows Figure 5 As shown, it can be seen from the figure that the four obvious characteristic peaks of black phosphorus are at 17.22°, 26.53°, 34.62°, and 52.41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com