Powdered cream essence and preparation method thereof

A technology of cream powder flavor and cream powder, which is applied in the field of flavors and fragrances, can solve the problems of weakened aroma intensity, insufficient flavor aroma, poor stability, etc., and achieve the effects of reducing aroma, good adsorption and dissolution, and improving temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

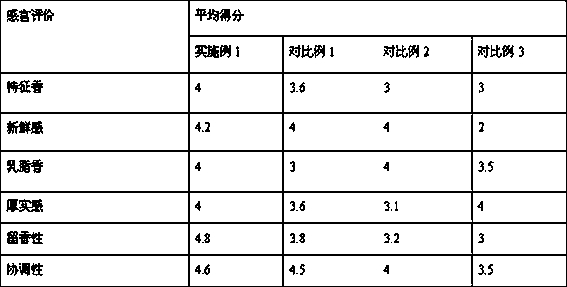

Examples

Embodiment 1

[0027] A cream powder essence, its raw material comprises by weight: 100 parts of butter enzyme hydrolyzate, 1.5 parts of cream base, 15 parts of maltodextrin and 3 parts of octenyl succinic acid starch;

[0028] The cream fragrance base is composed of the following components in parts by weight: 1 part of diacetyl, 0.41 parts of ethyl acetate, 0.2 parts of 2-heptanone, 0.3 parts of butyl decanolactone, 0.7 parts of gamma caprylactone, 0.05 parts of ethyl ester, 0.2 parts of caprylic acid, 0.3 parts of capric acid, 0.35 parts of ethyl myristate, 0.8 parts of vanillin, 50 parts of caprylic acid glyceride;

[0029] Described cream hydrolyzate is prepared by the steps of following order:

[0030] (1) Mix anhydrous cream and purified water in a ratio of 80:20 by weight, and stir evenly at room temperature to obtain a homogeneous cream mixture;

[0031] (2) Heat the above-mentioned homogeneous cream mixture to 68-70°C, keep it for 30 minutes, then rapidly cool it to 4-5°C for ster...

Embodiment 2

[0038] A cream powder essence, its raw material comprises by weight: 85 parts of cream enzyme hydrolyzate, 3 parts of cream base, 20 parts of maltodextrin and 2.5 parts of octenyl succinic acid starch;

[0039] The cream fragrance base is composed of the following components in parts by weight: 1 part of diacetyl, 0.3 parts of ethyl acetate, 0.2 parts of 2-heptanone, 0.8 parts of butyl decanolactone, 0.7 parts of gamma caprylactone, 0.15 parts of ethyl ester, 0.2 parts of caprylic acid, 0.3 parts of capric acid, 0.35 parts of ethyl myristate, 0.8 parts of vanillin, 50 parts of caprylic acid glyceride;

[0040] Described cream hydrolyzate is prepared by the steps of following order:

[0041] (1) Mix anhydrous cream and purified water in a ratio of 80:20 by weight, and stir evenly at room temperature to obtain a homogeneous cream mixture;

[0042] (2) Heat the above-mentioned homogeneous cream mixture to 68-70°C, keep it for 30 minutes, then rapidly cool it to 4-5°C for sterili...

Embodiment 3

[0049] A cream powder essence, its raw material comprises by weight: 80 parts of cream enzyme hydrolyzate, 3 parts of cream base, 15 parts of maltodextrin and 2.5 parts of octenyl succinic acid starch;

[0050] The cream fragrance base is composed of the following components in parts by weight: 1 part of diacetyl, 0.41 parts of ethyl acetate, 0.2 parts of 2-heptanone, 0.3 parts of butyl decanolactone, 0.7 parts of gamma caprylactone, 0.05 parts of ethyl ester, 0.2 parts of caprylic acid, 0.3 parts of capric acid, 0.35 parts of ethyl myristate, 0.8 parts of vanillin, 50 parts of caprylic acid glyceride;

[0051]Described cream hydrolyzate is prepared by the steps of following order:

[0052] (1) Mix anhydrous cream and purified water in a ratio of 80:20 by weight, and stir evenly at room temperature to obtain a homogeneous cream mixture;

[0053] (2) Heat the above-mentioned homogeneous cream mixture to 68-70°C, keep it for 30 minutes, then rapidly cool it to 4-5°C for sterili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com