Carbon commutator and manufacturing method thereof

A technology of carbon commutator and manufacturing method, which is applied in the field of carbon commutator and its manufacturing, can solve the problem of detachment of carbon basic body and commutator piece, and achieve high connection structure strength, long service life and good connection firmness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

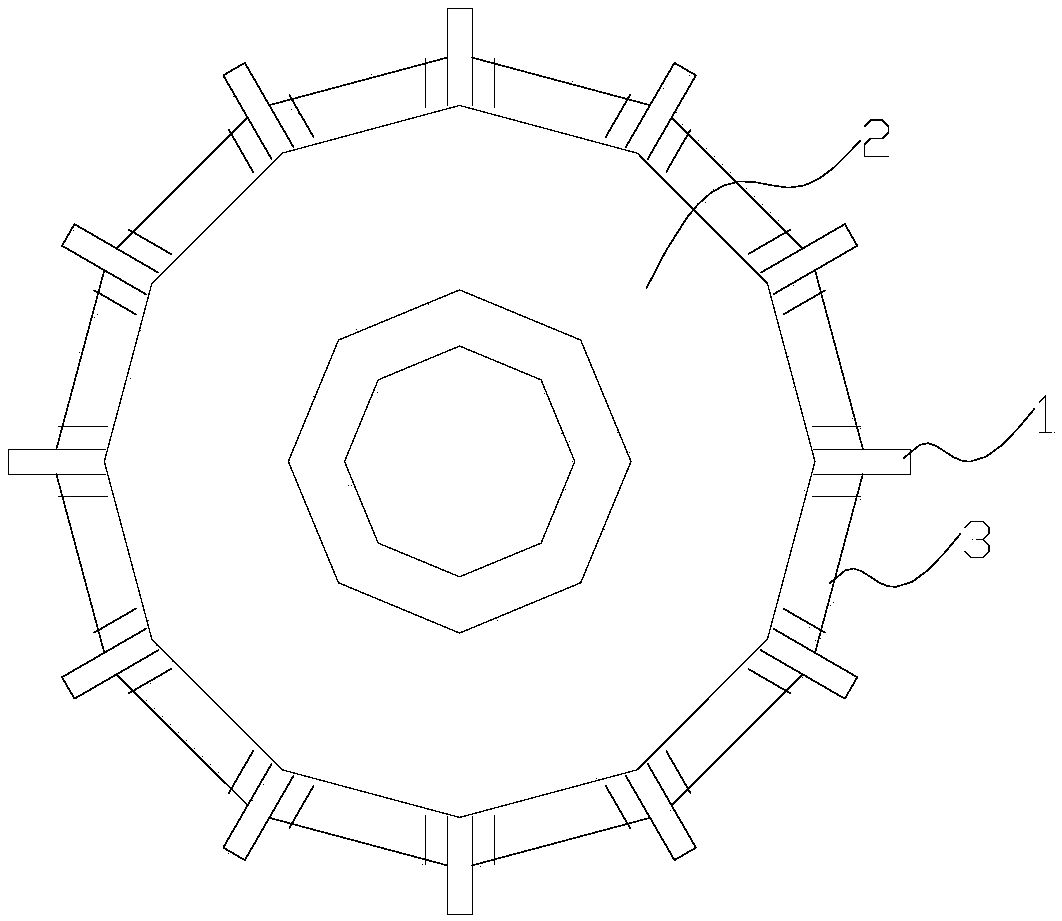

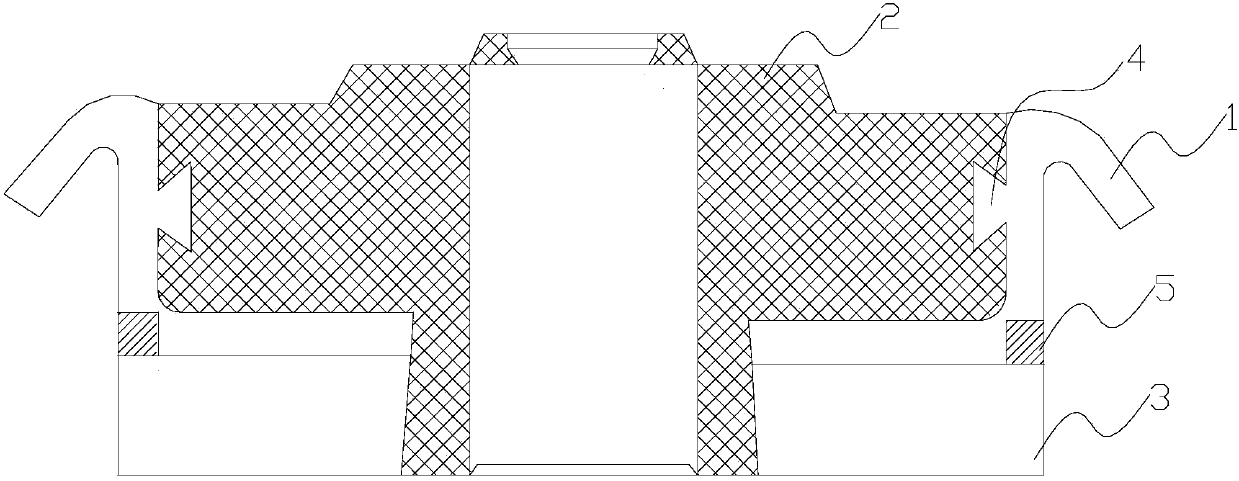

[0030] The carbon commutator includes a copper bracket, an insulating base and a carbon plate. One surface of the copper bracket and the carbon plate are brazed and connected by solder paste in a vacuum state. The other surface of the copper bracket is provided with an insulating base. The copper There is a longitudinal protrusion at the connection between the bracket and the insulating base, the longitudinal protrusion of the copper bracket is implanted inside the insulating base, and the connection between the copper bracket and the carbon plate is provided with a horizontal protrusion, and the horizontal protrusion is embedded inside the carbon plate , the central hole of the insulating base is on the same vertical line as the central hole of the copper bracket and the carbon plate.

[0031] In the present invention, the insulating base is provided with a raised circular pedestal, and the circular pedestal is provided with an inner annular step.

[0032] In the present inve...

Embodiment 2

[0042] The carbon commutator includes a copper bracket, an insulating base and a carbon plate. One surface of the copper bracket and the carbon plate are brazed and connected by solder paste in a vacuum state. The other surface of the copper bracket is provided with an insulating base. The copper There is a longitudinal protrusion at the connection between the bracket and the insulating base, the longitudinal protrusion of the copper bracket is implanted inside the insulating base, and the connection between the copper bracket and the carbon plate is provided with a horizontal protrusion, and the horizontal protrusion is embedded inside the carbon plate , the central hole of the insulating base is on the same vertical line as the central hole of the copper bracket and the carbon plate.

[0043] In the present invention, the insulating base is provided with a raised circular pedestal, and the circular pedestal is provided with an inner annular step.

[0044] In the present inve...

Embodiment 3

[0054] The carbon commutator includes a copper bracket, an insulating base and a carbon plate. One surface of the copper bracket and the carbon plate are brazed and connected by solder paste in a vacuum state. The other surface of the copper bracket is provided with an insulating base. The copper There is a longitudinal protrusion at the connection between the bracket and the insulating base, the longitudinal protrusion of the copper bracket is implanted inside the insulating base, and the connection between the copper bracket and the carbon plate is provided with a horizontal protrusion, and the horizontal protrusion is embedded inside the carbon plate , the central hole of the insulating base is on the same vertical line as the central hole of the copper bracket and the carbon plate.

[0055] In the present invention, the insulating base is provided with a raised circular pedestal, and the circular pedestal is provided with an inner annular step.

[0056] In the present inve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com