Time-inversion super-resolution pipeline leakage monitoring method

A time-reversal and super-resolution technology, applied in the application of electrical devices to test fluid tightness, etc., can solve the problem of low practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

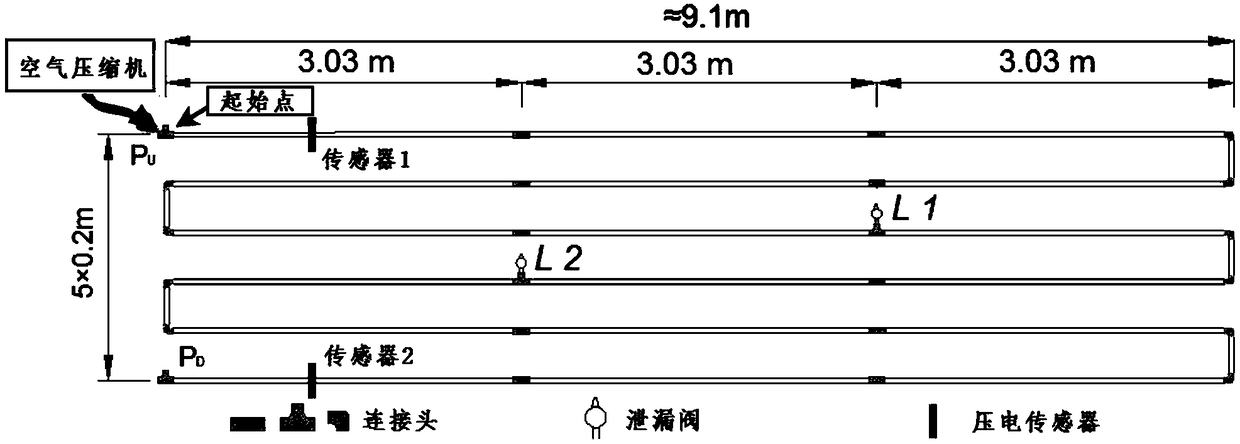

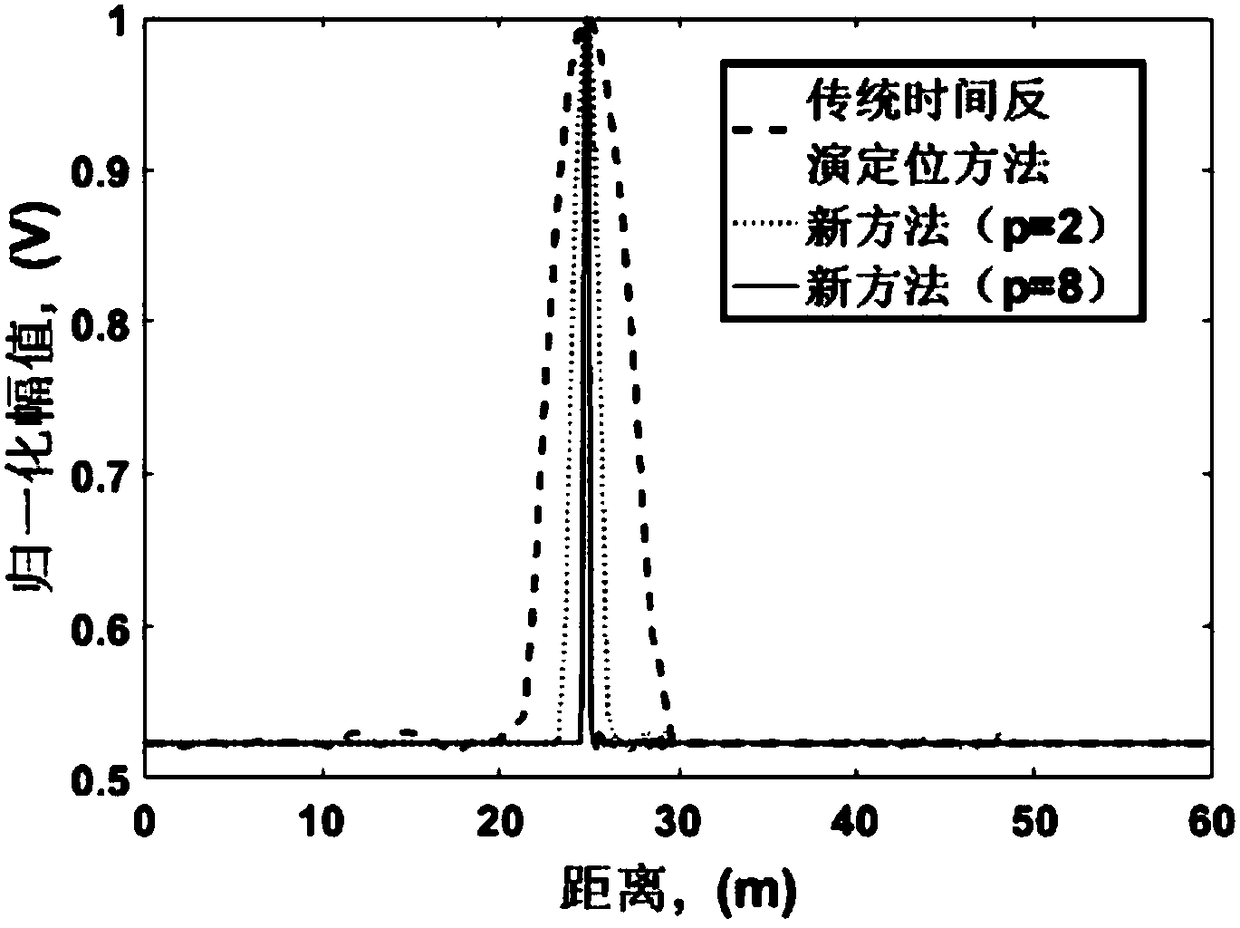

[0091] The present invention will be further described below in conjunction with accompanying drawing:

[0092] The present invention comprises the following steps:

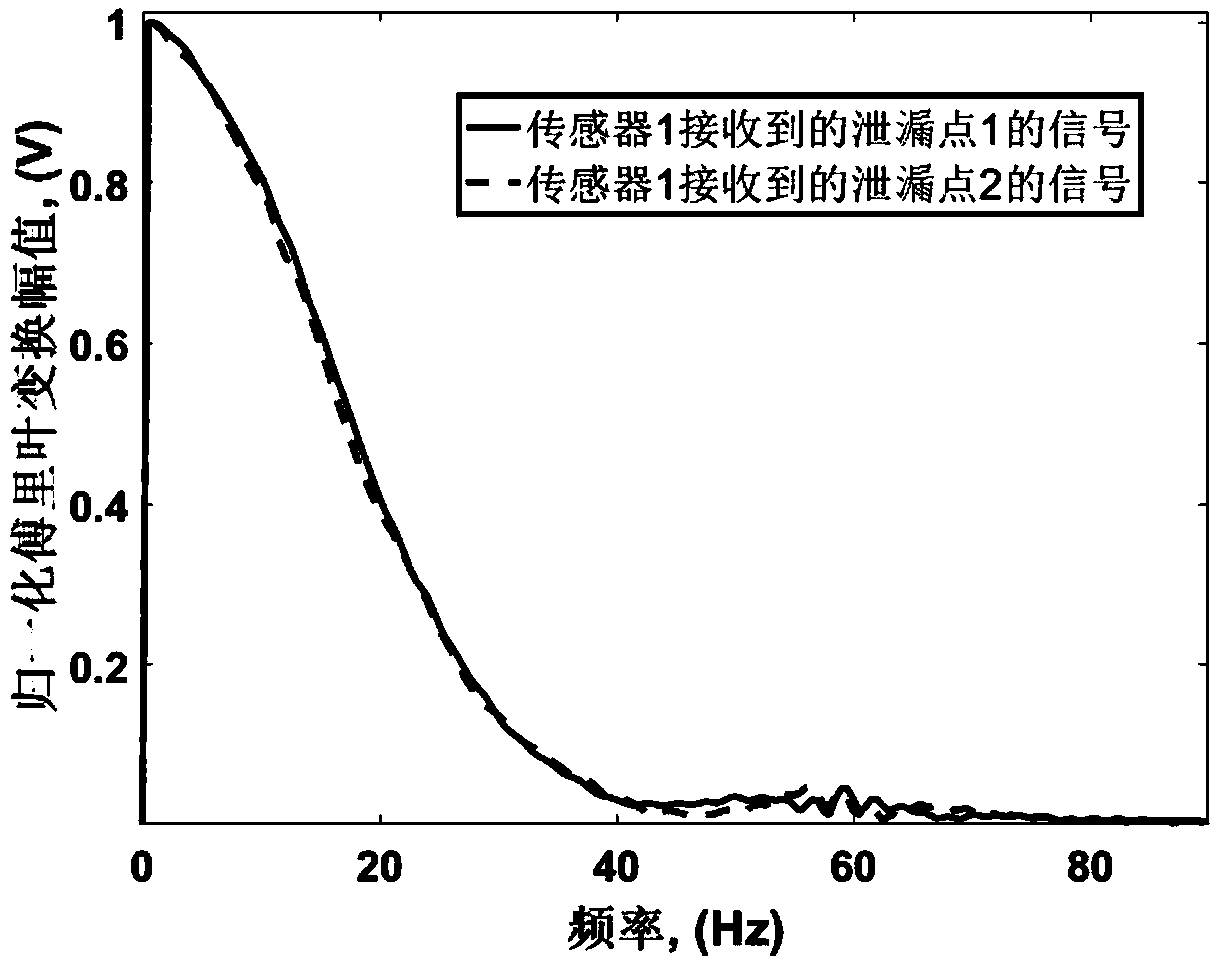

[0093] Two piezoelectric sensors, namely piezoelectric sensor 1 and piezoelectric sensor 2, are placed at both ends of the gas pipeline to detect the negative pressure wave signal generated during leakage; the leak point is located at r L , the negative pressure wave signal generated by the leak is e(r L ,t); let r L and r n The channel impulse response function between

[0094] h m (r n ,r L ,t)=a n,L,m δ(t-t n,L,m ) (1)

[0095] Among them, a n,L,m for r L and r n The signal attenuation coefficient between, δ(t-t n,L,m ) is the impulse signal, t n,L,m for the negative pressure wave at r L and r n The propagation time between , the symbol "m" represents the corresponding function obtained by measurement;

[0096] Then, at r n The negative pressure wave signal received by the n-th sensor is expr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com