Hybrid excitation blade-wheel generator

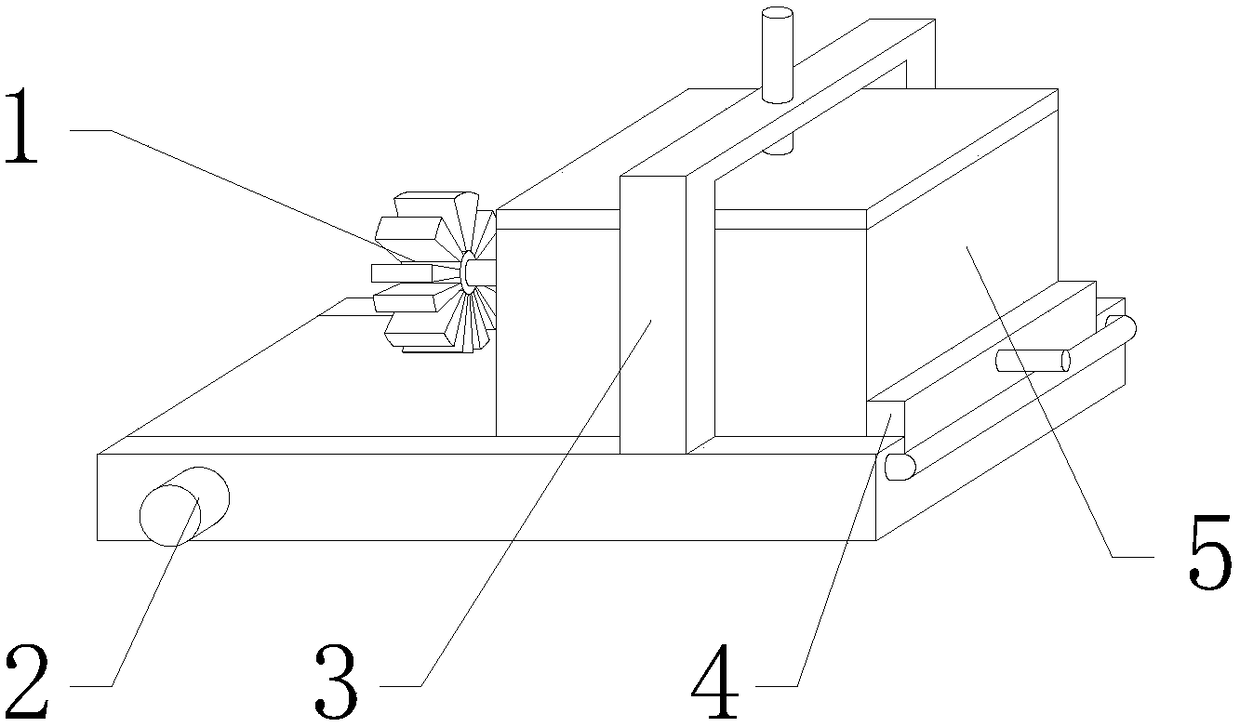

A hybrid excitation and generator technology, used in hydropower, engine components, machines/engines, etc., can solve the problems of low fixing effect, inconvenient cleaning, troublesome installation and disassembly, etc., to improve the supporting and fixing effect, improve the use effect, and facilitate the moving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

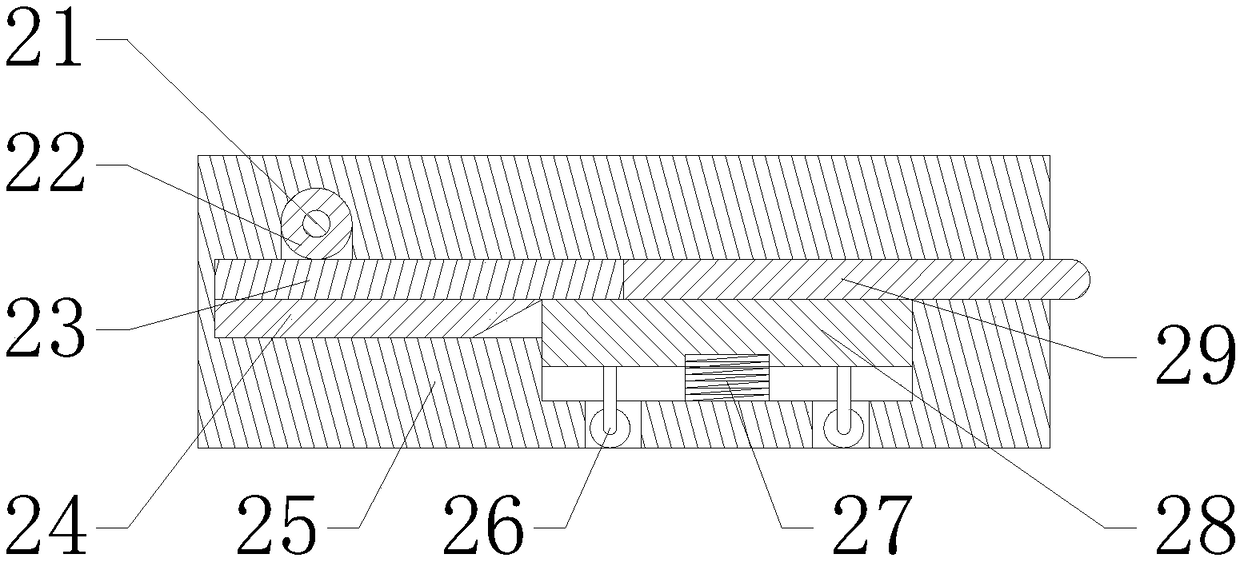

[0026] Specific implementation method: in actual use, the user starts the motor 21, and the motor 21 drives the circular gear 22 to rotate. Because the circular gear 22 and the rack bar 23 are geared, the circular gear 22 rotates to drive the rack bar 23 Moving to the right, the rack bar 23 moves to the right and simultaneously drives the moving plate 24 and the handle bar 29 to move to the right. Because the cross section of the moving plate 24 and the connecting plate 41 is trapezoidal, the moving plate 24 moves to the right to drive the base plate 25 upwards. Move, the base plate 25 moves upwards to compress the spring one 27, and at the same time the base plate 25 moves upwards to separate from the ground, then the handle bar 29 moves to the right and is removed from the inside of the base plate 25, and then the user holds the handle bar 29, And push the bar to the left, and then realize moving this device, this design has improved moving effect.

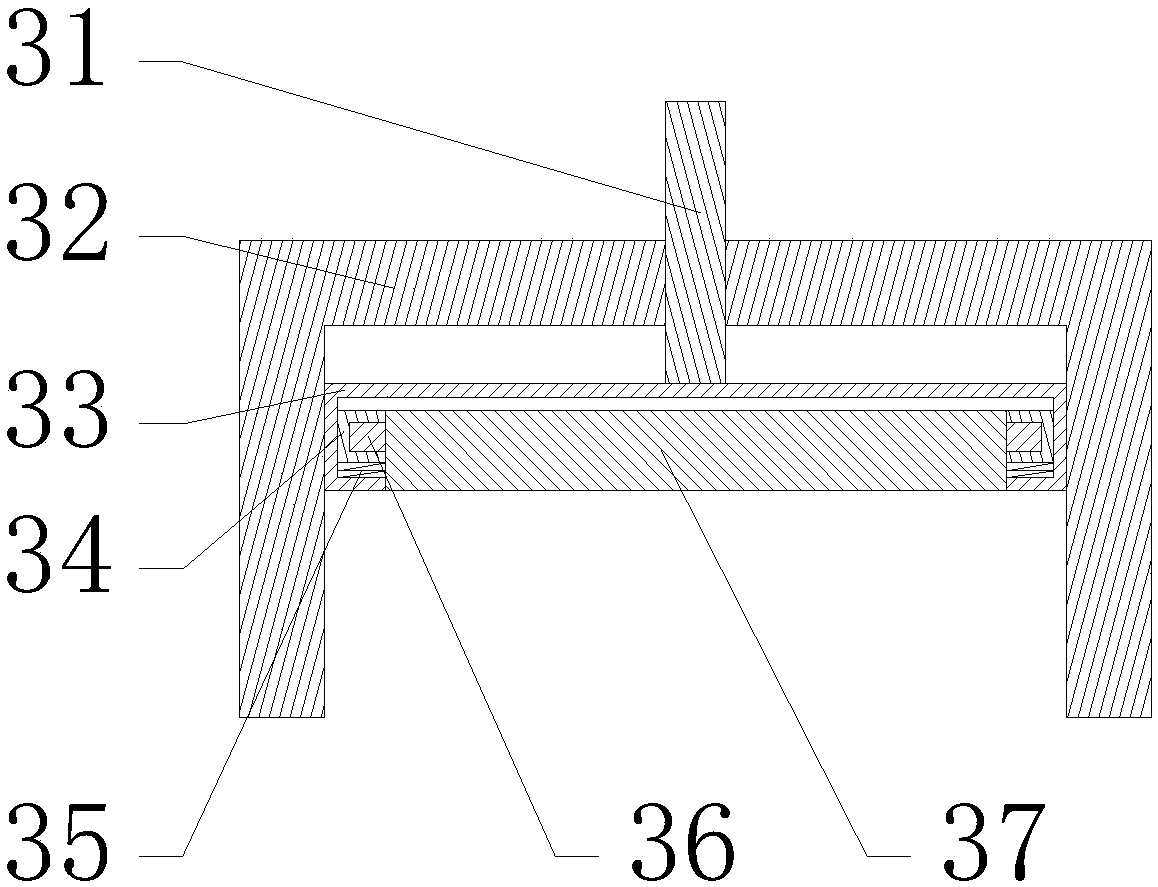

[0027] When a large amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com