Automatic grouting device for well cementing sleeve

An automatic grouting and casing technology, which is applied to the valve device of wellbore/well, wellbore/well components, earth-moving drilling, etc. grouting and other problems to achieve the effect of reducing steps, saving production costs and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

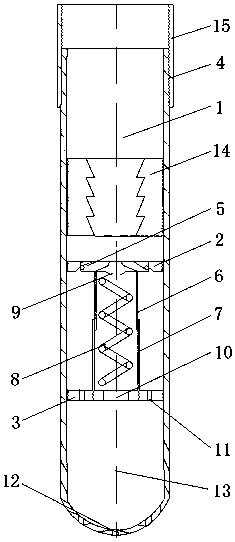

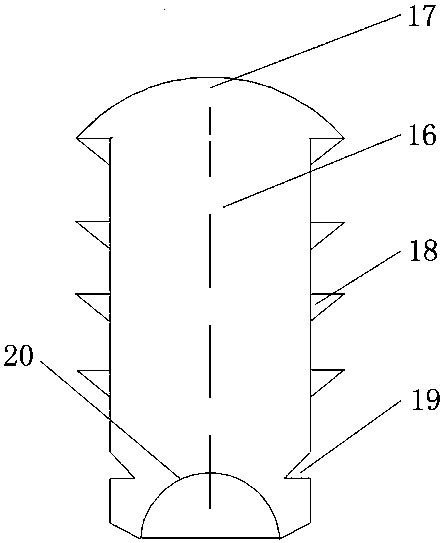

[0031] Such as Figure 1 to Figure 2 As shown, it is a specific embodiment of the automatic casing grouting device for well cementing in the present invention: the automatic casing grouting device for well cementing includes a device main body 1 for mud or drilling fluid or other fluids to pass through, and in the device main body 1 A check valve structure capable of controlling the on-off of the main body 1 of the device is provided. The top 4 of the main body of the device is provided with external threads connected in series with other casings. The bottom 13 of the main body of the device is a shoe structure, which can protect the main body 1 of the device.

[0032]In the middle of the main body 1 of the device, there are two supporting rings parallel to each other, which are the valve block support seat 2 and the spring seat 3 respectively. Both the valve block support seat 2 and the spring seat 3 are provided with central holes for fluid to pass through. Between the valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com