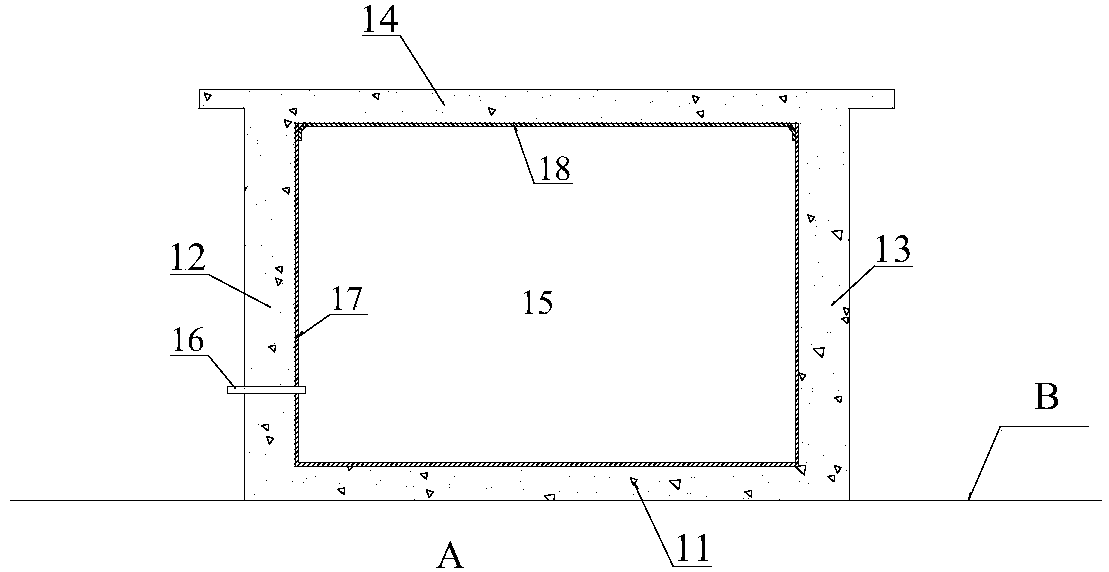

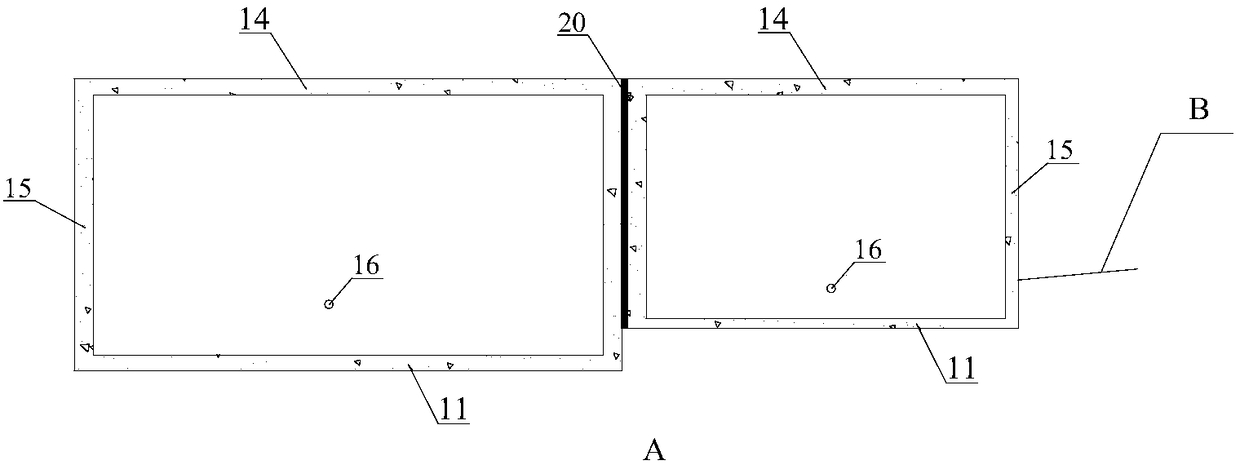

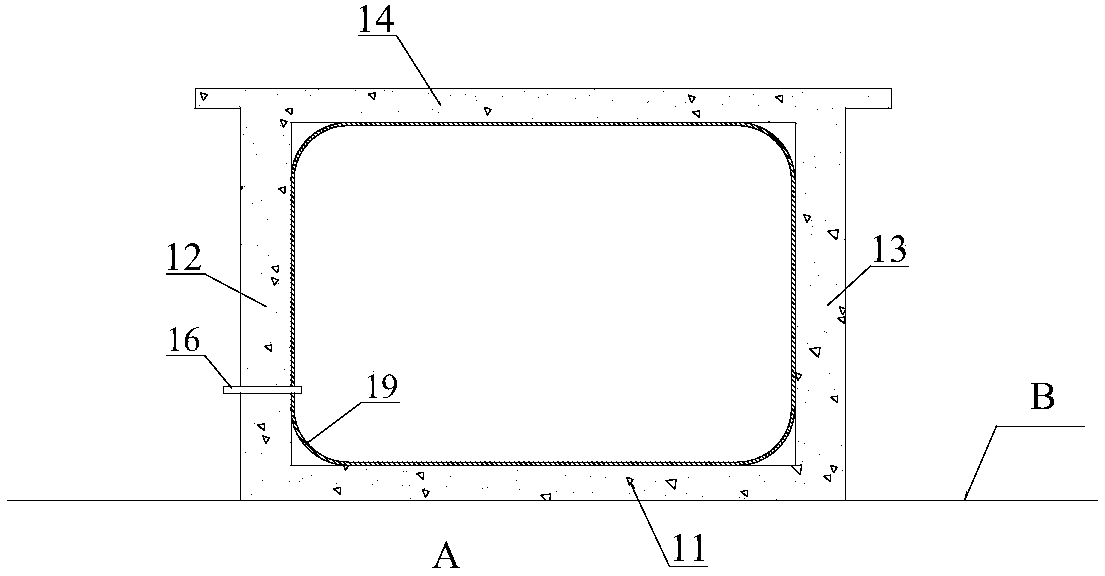

Pressure box-type high-speed railway bed structure and construction method

A high-speed railway and construction method technology, applied in the field of geotechnical engineering, can solve the problems of high subgrade construction cost, precious farmland, lack of high-quality fillers, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] Take a ballastless track high-speed railway embankment project as an example.

[0033] 1. The traditional embankment structure is adopted, the filling height is 7m, the thickness of the foundation soil layer is 15m, the length of the embankment is 500m, and the transportation distance of high-quality filler is 50Km (including graded gravel on the surface of the subgrade, the average price is about 160 yuan / m 3 ), and the land use cost is 150,000 yuan / mu. Filling section square 171.5m 2 , the foundation is treated with CFG piles, the treatment width is 35m, the depth is 15mm, the pile spacing is 1.6m, the land width is 45m, the slope protection cost is 800 yuan / m, and the cross-sectional area of the drainage ditch is 1.3m 2 . The estimated cost of subgrade works is as follows:

[0034] Packing price: 171.5m 2 *500m*160 yuan / m 3 = 13.72 million yuan;

[0035] Foundation CFG pile engineering cost: 35m*500m*15m / 1.6m / 1.6m*140 yuan / m=14.356 million yuan;

[0036] Lan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com