Brazing system and working method thereof

A working method and brazing technology, which is applied to welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of reducing the service life of vacuum pump units, low service life, and reducing work efficiency, so as to improve heat utilization efficiency and improve use Longevity, the effect of ensuring the quality of brazing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

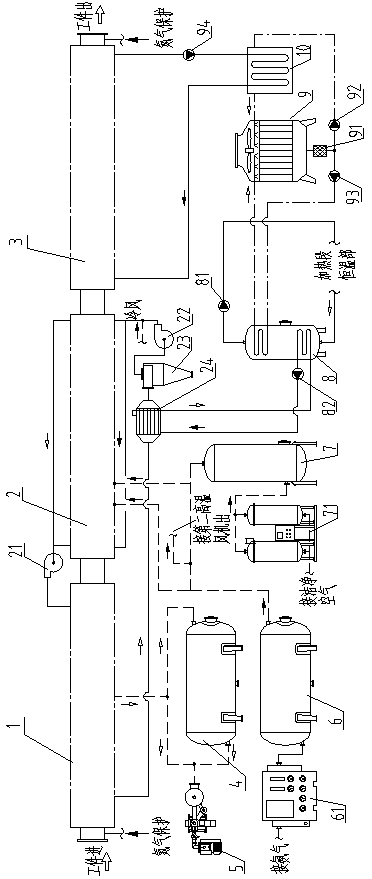

[0040] Such as figure 1 Described: a brazing system, including a ventilation section 1, an electric heating section 2, a cooling section 3, a vacuum system, a gas storage system, a constant temperature system, an air cooling system, a heat recovery circulation system and a water cooling system.

[0041] The vacuum system includes a vacuum tank 4 and a vacuum pump group 5 . One of the branches of the air outlet of the heat exchange section 1 is connected to the air inlet of the vacuum tank 4, and the other branch is connected to the vacuum pump group 5, which is also connected to the vacuum tank 4, and the vacuum tank 4 is coarse to the air intake of the ventilation section 1. Vacuuming, the vacuum pump group 5 performs fine vacuuming on the ventilation section 1, and the vacuum pump group 5 pre-evacuates the vacuum tank 4.

[0042] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com