A novel functional jelly candy and its preparation method

A technology of functional and functional components, applied in confectionery, confectionery industry, food science, etc., can solve the problems of difficult control of product embedding quality, low DHA content of products, and small proportion of oil, so as to prevent Senile nervous system disease, relieve mental stress, good taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

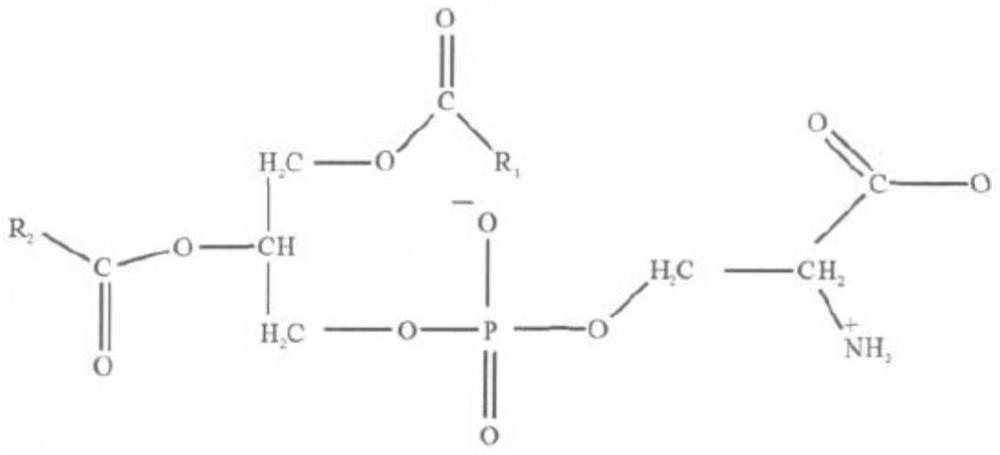

Method used

Image

Examples

Embodiment 1

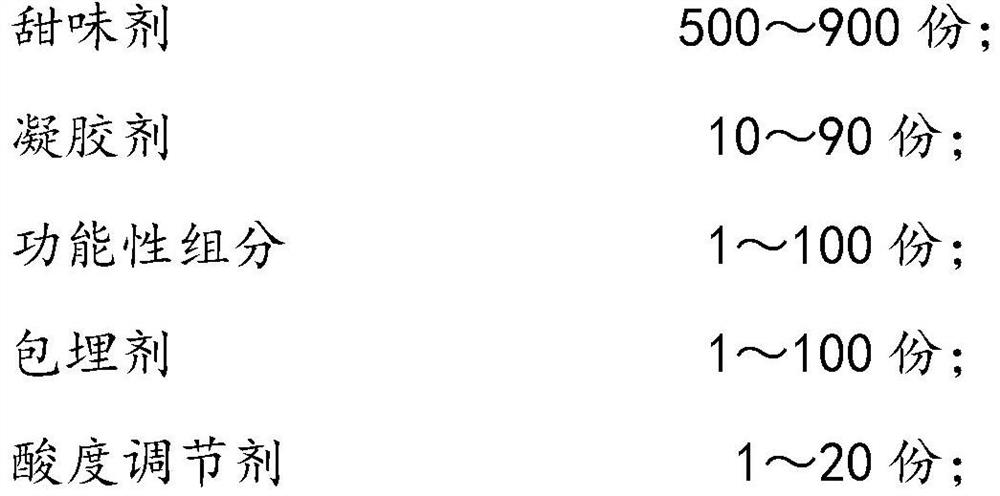

[0051] An orange peacum flavor PS soft sugar, including the following weight parts:

[0052]

[0053] The preparation steps of the above PS soft sugar are as follows:

[0054] 1) Formulate the PS mixture: 100 parts of β-cyclodextrin, 100 parts of PS, 100 parts of purified water, mix well, mix well;

[0055] 2) Formulated acid: 8 copies of citric acid, 2 parts lactic acid and 2 parts of malic acid, dissolved in 15 parts of hot water;

[0056] 3) Preparation Glue: 60 parts of gelatin and hot water are mixed into gelatin completely dissolved, and the amount of water is added to 1.1 times of gelatin;

[0057] 4) Cooking: 255 parts of glucose syrup, 220 white sugar, 25 parts of sorbitol and 60 purified water, heat dissolved, cooked to cook until the solid content is 90%, and the obtained material is stressed.

[0058] 5) Addition: Addition to 4) Add Gluid, PS mixture, acid solution, and peach smell, peach flavor, rouge orange, and transferred to a solid content of 75%, and insulation...

Embodiment 2

[0077] A yellow lemon-free sugar ps-DHA soft sugar, including the following weight parts:

[0078]

[0079]

[0080] The preparation steps of the above PS-DHA soft sugar are as follows:

[0081] 1) Preparation of PS-DHA mixed liquid: After fully dissolving 40 parts of Arabic, stir well with 10 copies, 30 galves, mix, mix well;

[0082] 2) Formulate the acid solution: 5 copies of citric acid, 5 parts of malic acid, and dissolve in 10 parts of hot water;

[0083] 3) Preparation Glue: Take 60 copper, heating water to the extragers and complete dissolution, adding water to 1.3 times of gelatin, give gelatin glue; 3 parts of agar and 30 purified water in the bucket, mix uniform , Stir, heating to 100 ° C to completely dissolve, resulting in agar fluid;

[0084] 4) Cooking: 630 parts of maltanol and 170 pieces of erythritol are placed in a sugar tank. After heating, the agar fluid is added, and the cooked is concentrated to a solid content of 80%, and the obtained liquid is ostentan...

Embodiment 3

[0101] A red strawberry algae oil, including raw materials of the following weight parts:

[0102]

[0103] The preparation steps of the above algal oil flexible are as follows:

[0104] 1) Configure algae oil mixed: After fully dissolving 5 Arabic gums, mix with 1 algae oil, stir well;

[0105] 2) Formulating the acid solution: Tested 14 copies of citric acid and dissolved in 10 parts of 70 ° C;

[0106] 3) Preparation of the collapse: Weighed 23 pectin, 150 copies of white sugar, 2 copies of citric acid, sodium 4 parts of dihydrate and 200 purified water in the sol take, heat dissolved, to obtain a pectin liquid;

[0107] 4) Cooking: 464 glucose syrups, 225 white sugar mixed with 80 parts of purified water, heat dissolved, add collapse, cooked to the solid product content of 85%, resulting in the liquid.

[0108] 5) Addition: Add 4) Add Algae oil mixture, strawberry juice, strawberry flavor, carmine red, acid solution, and prepared to a solid content of 80%;

[0109] 6) Pourin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com