Unmanned aerial vehicle

A technology of unmanned aerial vehicles and inner shells, applied in the field of unmanned aerial vehicles, can solve the problems of rising battery module costs, unguaranteed use stability and safety, unsatisfactory heat dissipation efficiency, etc., to ensure safety performance, ensure safe flight, and improve heating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

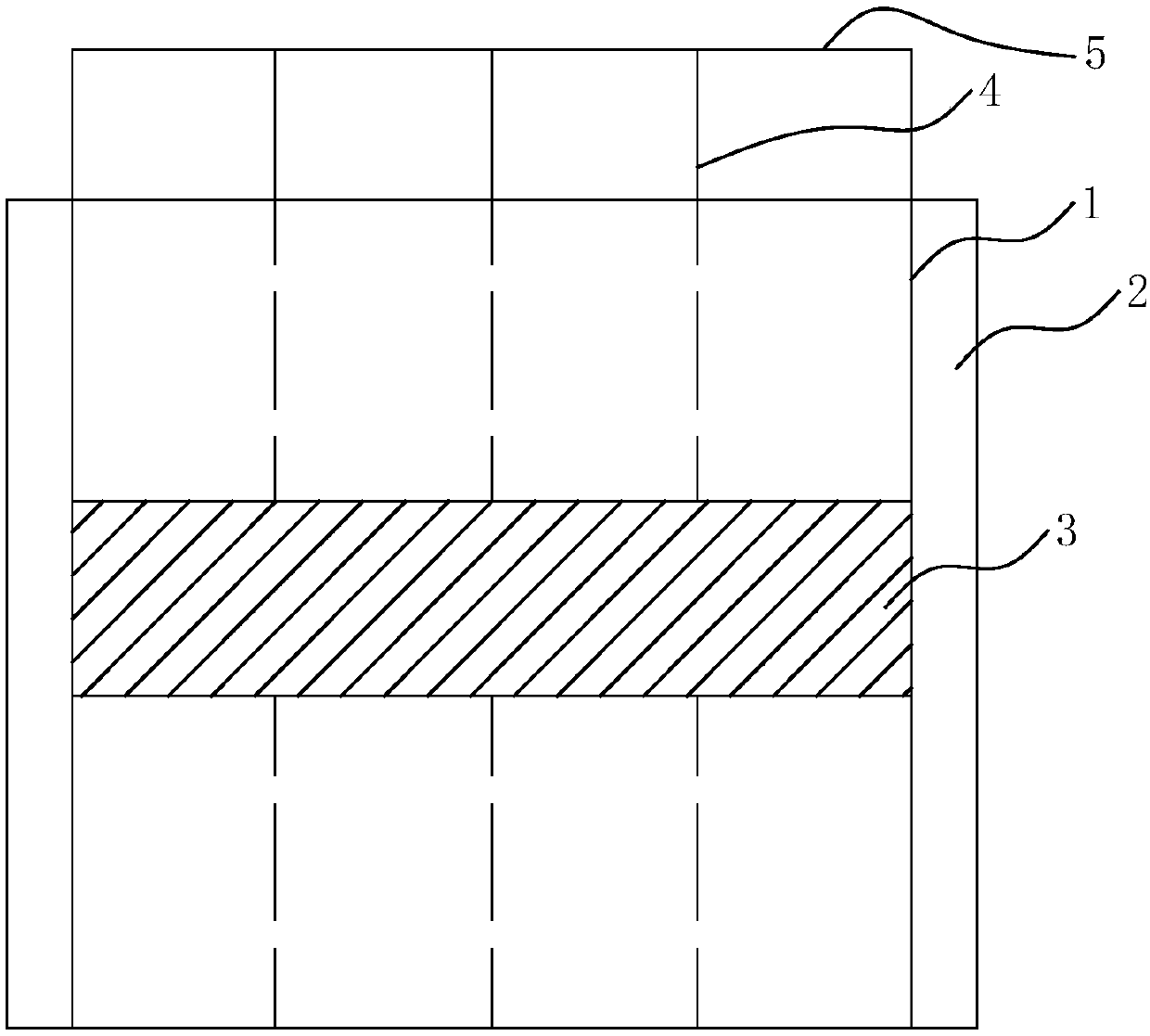

[0010] see figure 1 As shown, an unmanned aerial vehicle according to the embodiment of the present invention includes a battery module, and the battery module includes: an inner shell 1 and an outer shell 2, the inner shell 1 defines a battery cell installation space, and the inner shell 1 A heat conduction assembly is arranged between the outer shell 2, the heat conduction assembly includes a component 3 for absorbing or releasing heat, the component 3 includes a phase change material, and the inner shell is connected with a heating element 4 and a temperature sensor , the heating element 4 is used to heat the inner shell 1, the temperature sensor is used to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com