Thin film transistor, manufacturing method thereof, array substrate and display apparatus

A technology of thin film transistor and manufacturing method, which is applied in transistors, semiconductor/solid-state device manufacturing, electric solid-state devices and other directions, can solve problems such as affecting device stability and easily generating off-state current, so as to improve stability, improve display effect, The effect of reducing off-state current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

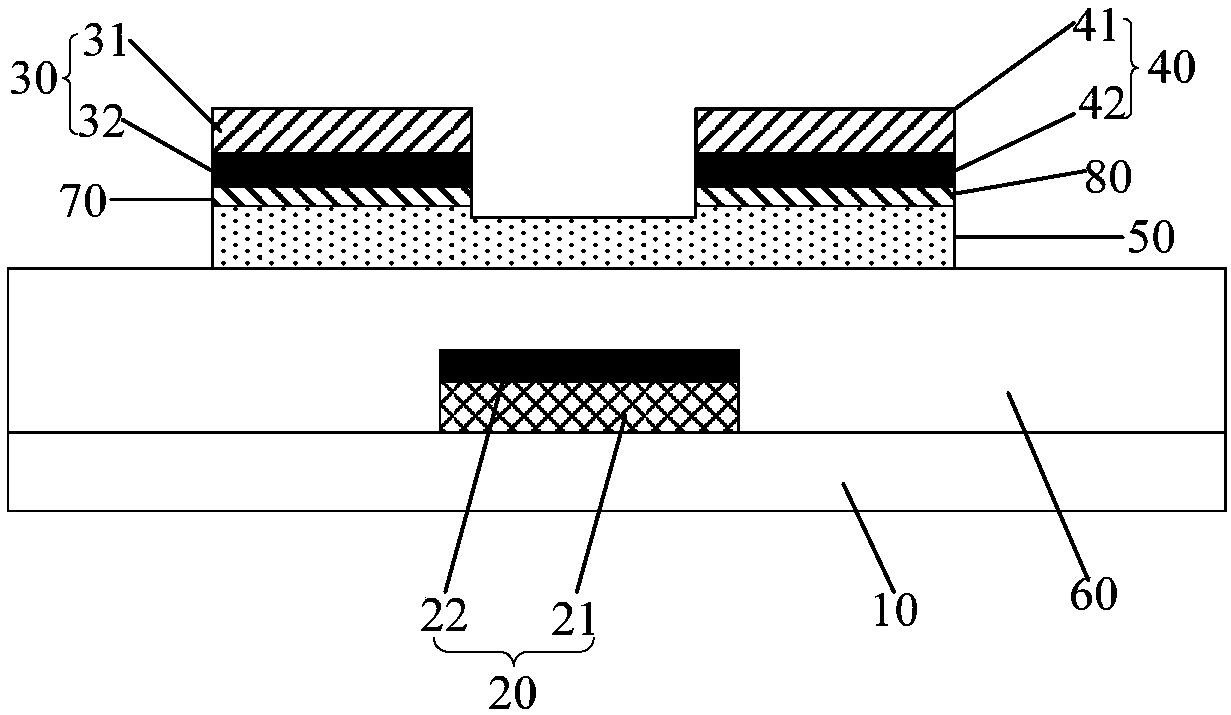

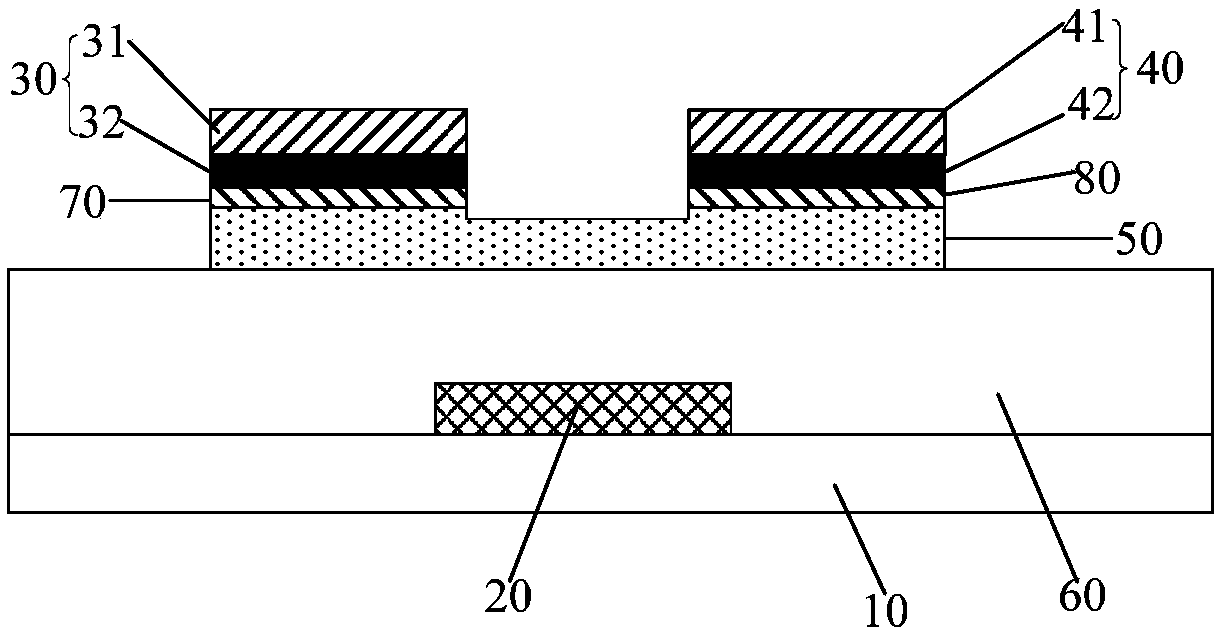

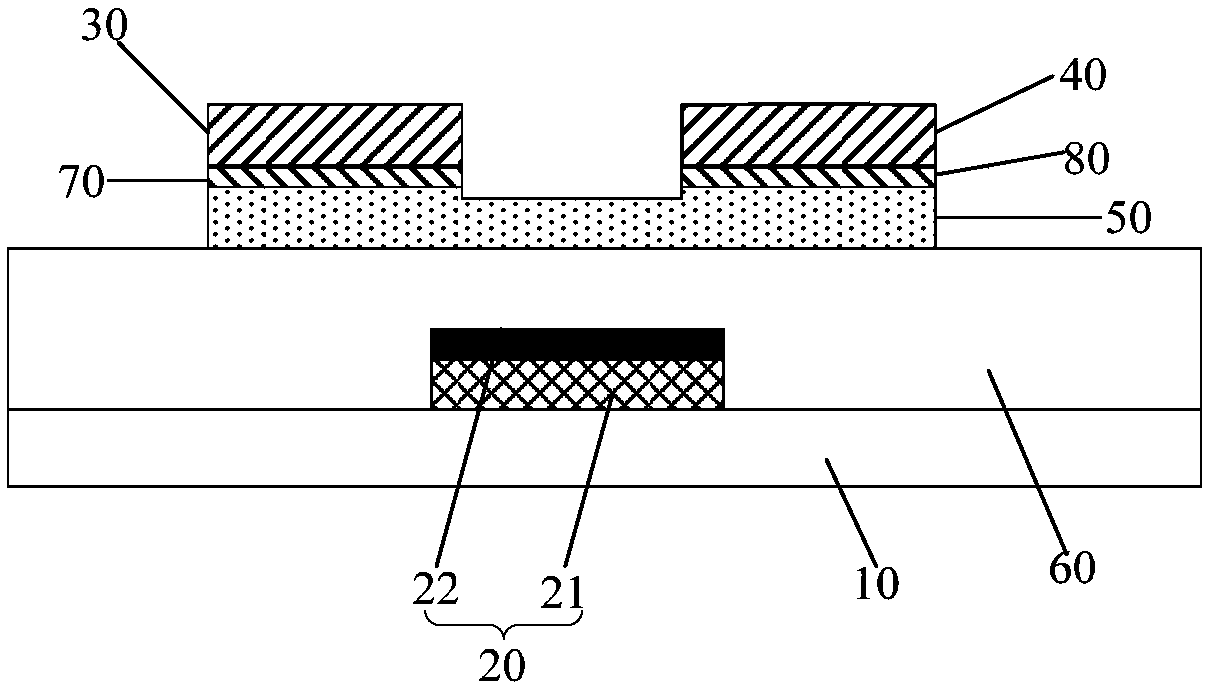

[0053] As an aspect of the present invention, a thin film transistor is provided, Figure 1 to Figure 6 Six structural schematic diagrams of thin film transistors are shown respectively, combined with Figure 1 to Figure 6 As shown, the thin film transistor includes a gate 20 , a source 30 , a drain 40 and an active layer 50 disposed on a substrate 10 , and both the source 30 and the drain 40 are electrically connected to the active layer 50 . At least one of the gate 20 , the source 30 and the drain 40 is a light-absorbing electrode, and the light-absorbing electrode includes an electrode body and a light-absorbing layer, and the light-absorbing layer is dispo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com