Optimization method of bending of wafer

An optimization method and bending technology, applied to electrical components, circuits, semiconductor devices, etc., can solve problems such as wafer quality degradation, wafer surface depressions or protrusions, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In the existing semiconductor device manufacturing technology, it is easy to appear the phenomenon that the surface of the wafer forms an overall depression or protrusion, which leads to the deterioration of the quality of the wafer in subsequent process steps such as bonding.

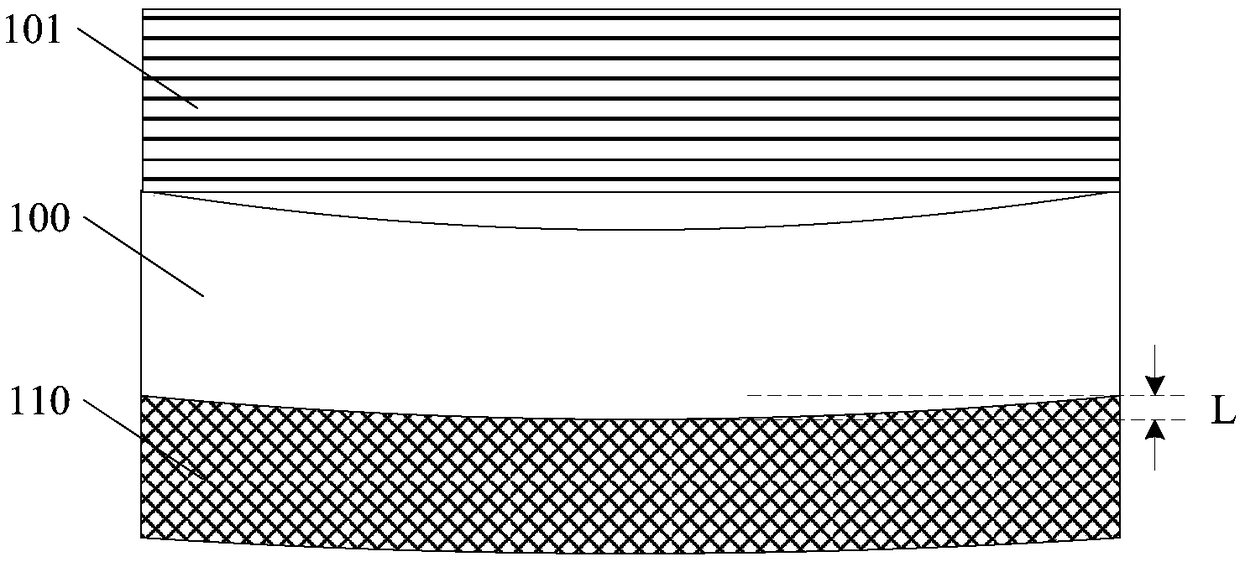

[0028] figure 1 It is a schematic cross-sectional structure diagram of a curved wafer in the prior art. Such as figure 1 As shown, the overall dishing of the wafer 100 occurs during the process, resulting in a decrease in quality in subsequent process steps such as bonding. Specifically, for example, when the device formed on the wafer 100 is a backside illumination-CMOS Image Sensors (BSI-CIS), the wafer 100 and the carrier wafer (Carrier Wafer) 101 need to be bonded , for other semiconductor devices, it may also be necessary to bond the wafer 100 to another device wafer (Device Wafer).

[0029] Wherein, the wafer 100 can be, for example, a device wafer, so that various semiconductor devices...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com