Anti-loose retaining type connection structure

A connection structure and anti-loosening technology, which is applied in the direction of connection components, threaded fasteners, screws, etc., can solve the problems of easy loosening and falling off, and achieve the effect of improving firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below, the technical solution of the present invention will be described in detail through specific examples.

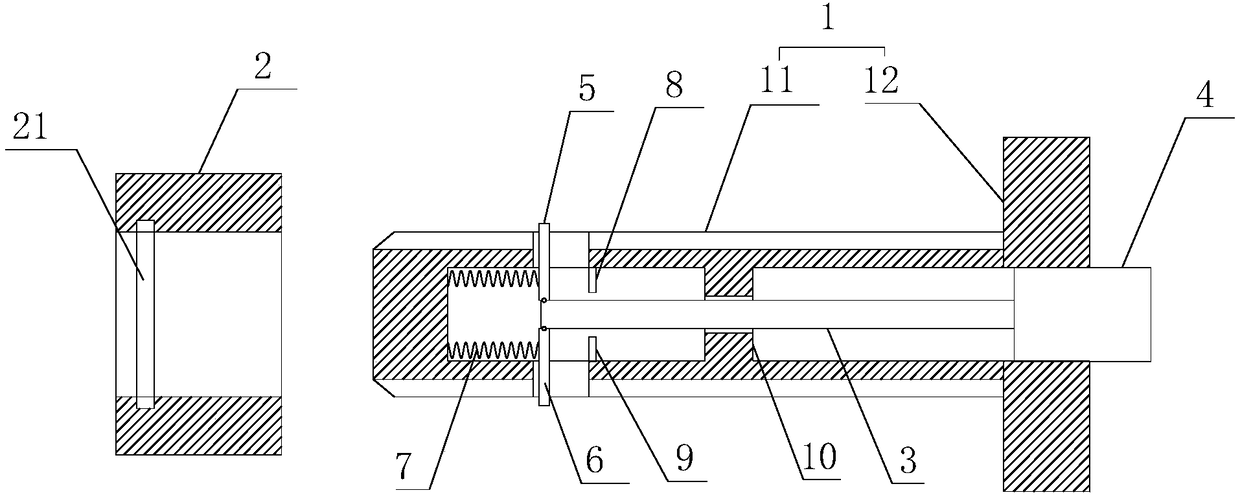

[0017] like figure 1 as shown, figure 1 It is an exploded view of an anti-loosening and anti-backward connection structure proposed by the present invention.

[0018] refer to figure 1 , an anti-loosening and anti-backward connection structure proposed by the embodiment of the present invention, including: a bolt 1 and a nut 2 adapted to the bolt 1, wherein: the bolt 1 includes a screw 11 and is located at one end of the screw 11 and connected to the screw 11 Fixed limit block 12, screw rod 11 inside is provided with a central cavity extending along its length direction, the side wall of screw rod 11 is provided with the first channel and the second channel leading to the central cavity, and the first channel, the second channel The channels are located on the same radial straight line.

[0019] One end of the center cavity close to the limit block 12 runs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com