Automobile air compressor with unloading gas storage oil mist separation cavity

A technology of oil mist separation and air compressor, which is applied in the direction of mechanical equipment, machine/engine, liquid variable capacity machinery, etc. It can solve the problems of unable to close the piston and cylinder, speed up the flow rate, and pollute the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

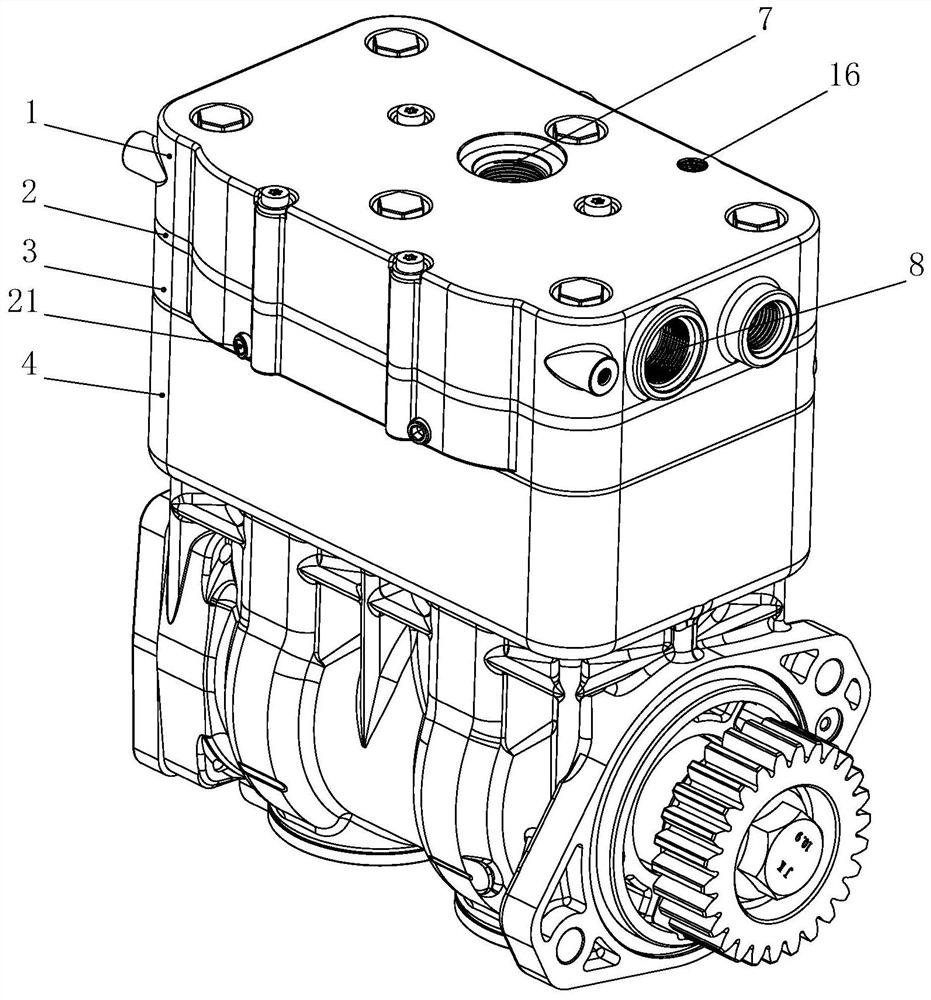

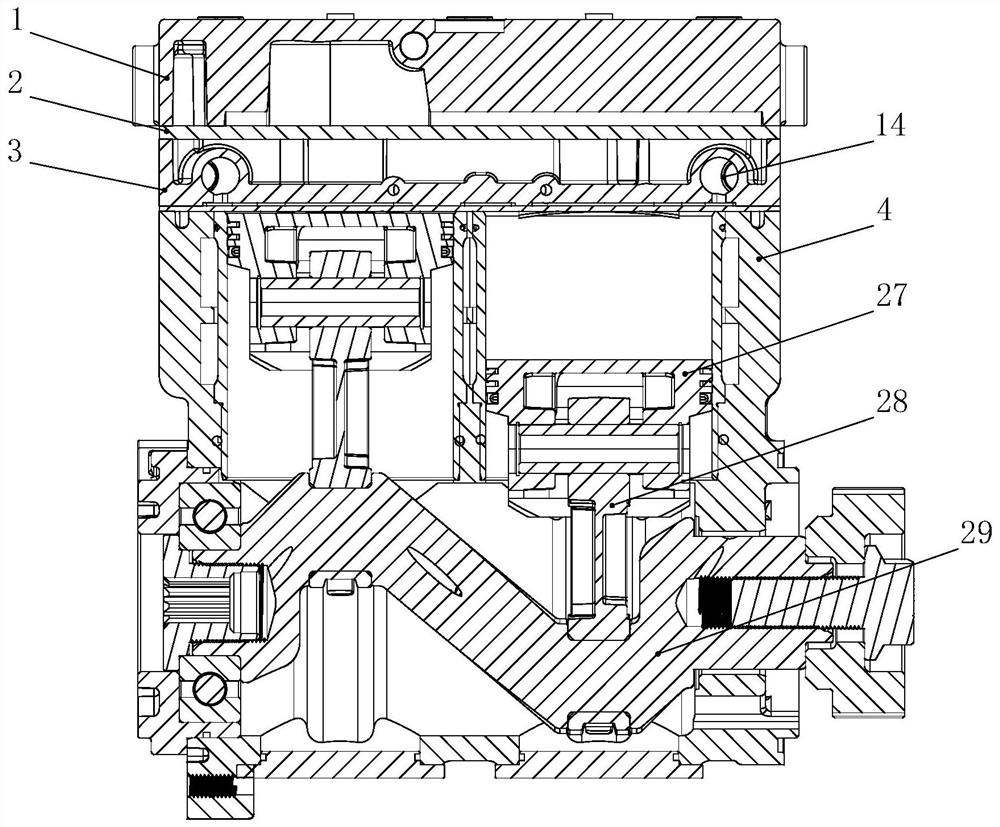

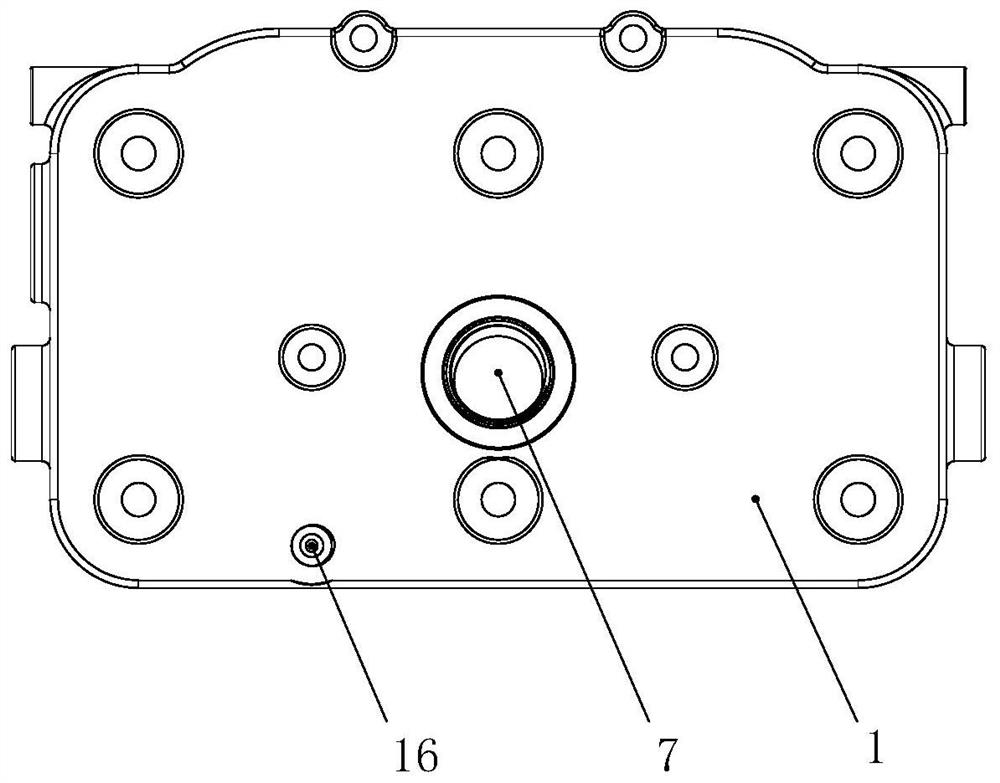

[0034] The present invention will be further described below with specific embodiment, see figure 1 -7:

[0035] An automotive air compressor with an unloading gas storage and oil mist separation chamber, including a cylinder head 1, an intermediate plate 2, a valve plate 3 and a crankcase 4 arranged in sequence from top to bottom, and the gap between the intermediate plate 2 and the valve plate 3 is An air intake chamber 5 and an exhaust chamber 6 are provided. The cylinder head 1 and the middle plate 2 are provided with an air inlet 7 communicating with the air intake chamber 5 and an exhaust port 8 communicating with the exhaust chamber 6. The valve plate 3 An air intake hole 9 communicated with the air intake chamber 5, an exhaust hole 10 communicated with the exhaust chamber 6, and a valve plate assembly respectively matched with the air intake hole 9 and the exhaust port 8 are provided on the cylinder head. 1 and the middle plate 2 are formed with an unloading gas stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com