Lubricating oil and application thereof

A lubricating oil and base oil technology, which is applied in the field of lubricating oil, can solve the problems of not being able to meet the rapid update of paper machines, and achieve good water separation, low friction coefficient, and excellent anti-rust effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

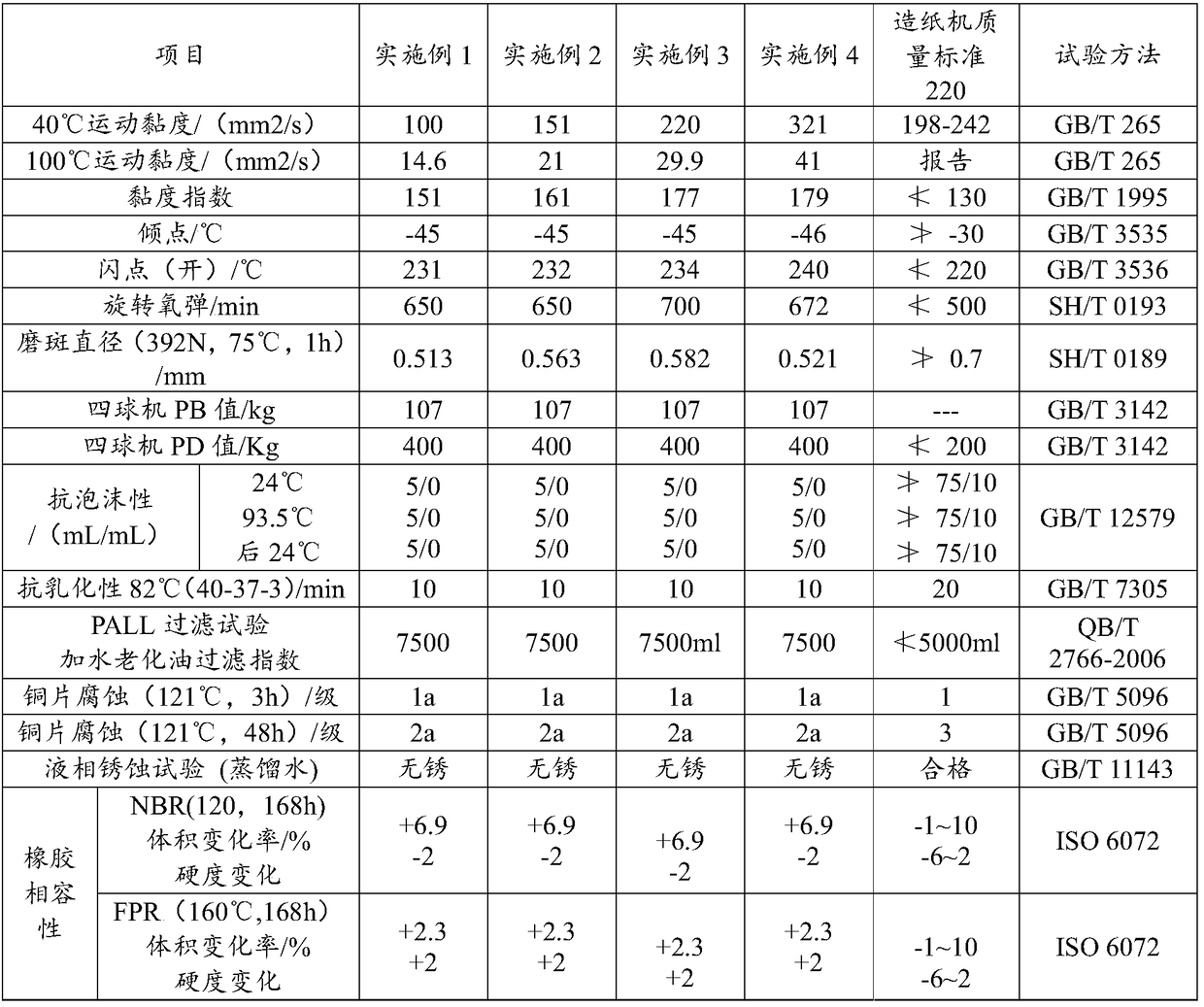

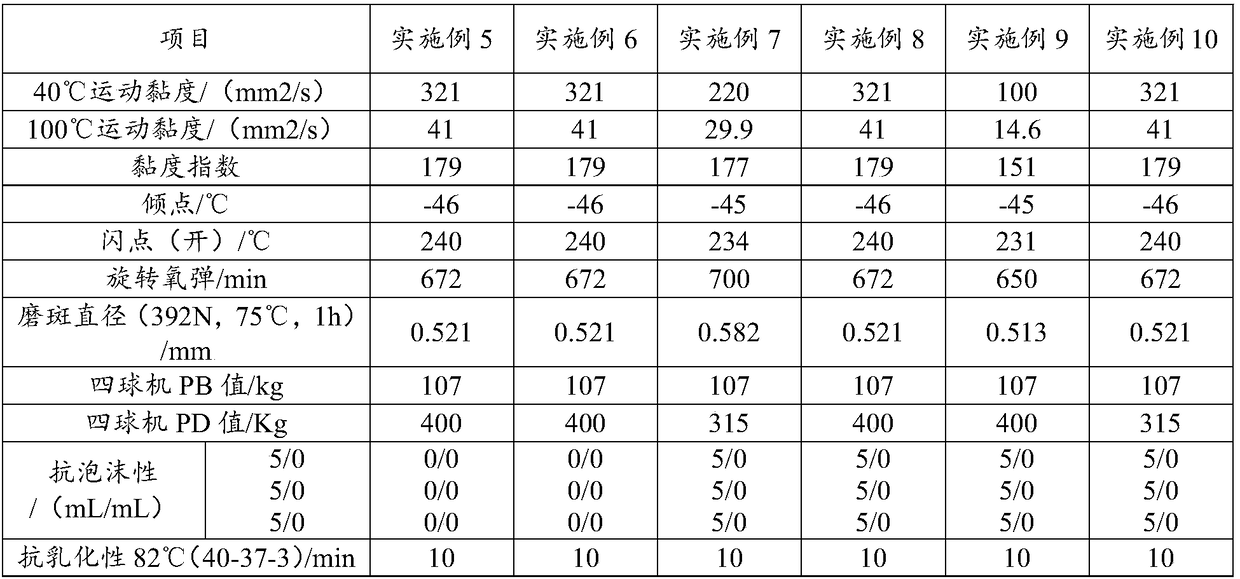

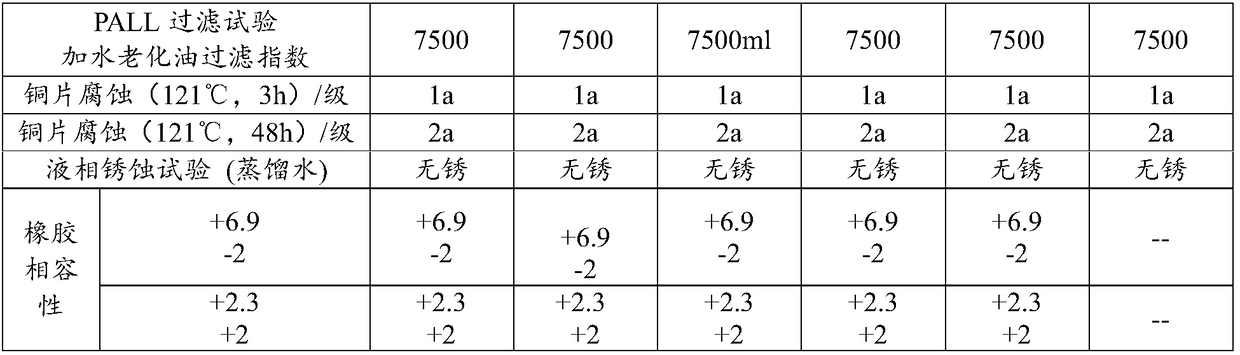

Examples

Embodiment 1

[0057] Get polyalphaolefin PAO10 31.6g, polyalphaolefin PAO40 66g, H573 (Munzing company produces) composite agent 2.4g, add the defoamer Foam Ban 155 (manufacturer Simin Oil Chemical Co., Ltd.) of 0.3‰ (weight); Mix the above raw materials and stir evenly to obtain.

Embodiment 2

[0059] Take 52.6g of polyalphaolefin PAO10, 45g of polyalphaolefin PAO40, 2.4g of H573 complex agent, add 0.3‰ (weight) of defoamer Foam Ban 155; mix the above raw materials, stir evenly, and obtain.

Embodiment 3

[0061] Take 34g of polyalphaolefin PAO10, 63.6g of polyalphaolefin PAO40, 2.4g of H573 complex agent, add 0.3‰ (weight) defoamer Foam Ban 155; mix the above raw materials, stir evenly, and obtain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com