Matte thermoplastic polyurethane elastomer with high physical properties and preparation method thereof

A thermoplastic polyurethane and elastomer technology, which is applied in the field of matte polyurethane elastomer and its preparation, can solve the problems of rough dispersed appearance, poor compatibility, and decreased physical properties, and achieve good cost advantages, low cost, and reduced deviation of TPU physical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

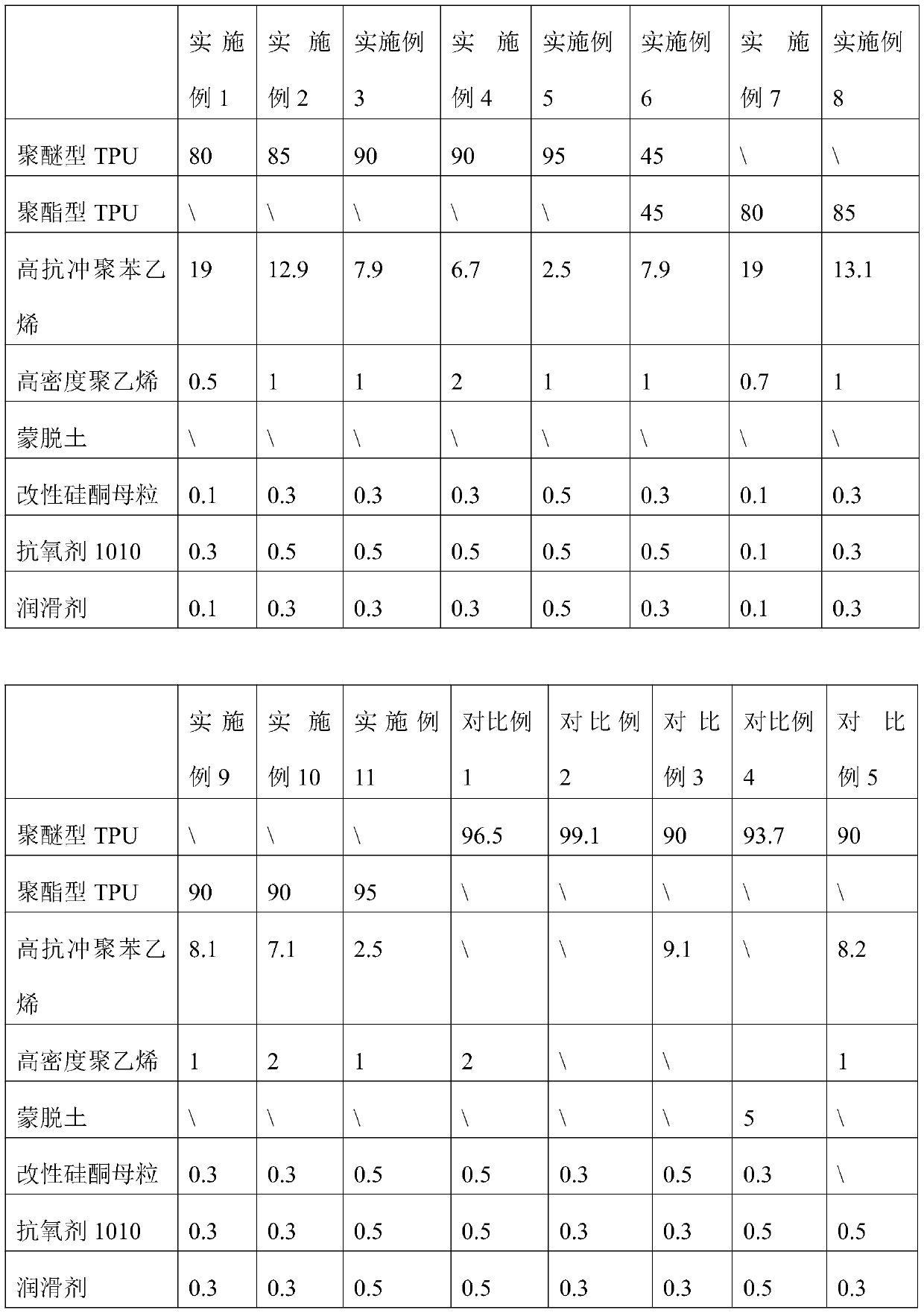

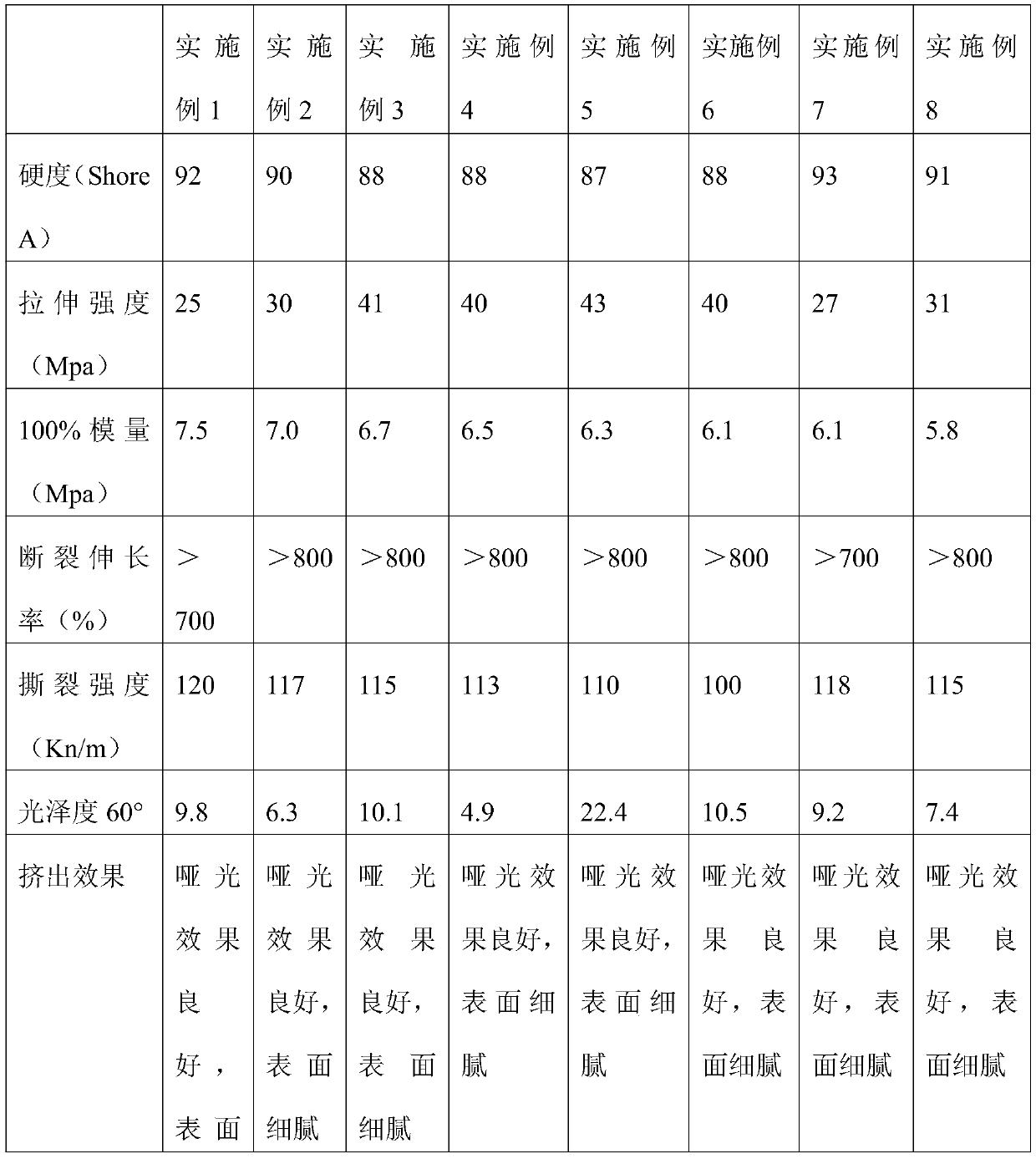

Embodiment 1~11 and comparative example 1~5

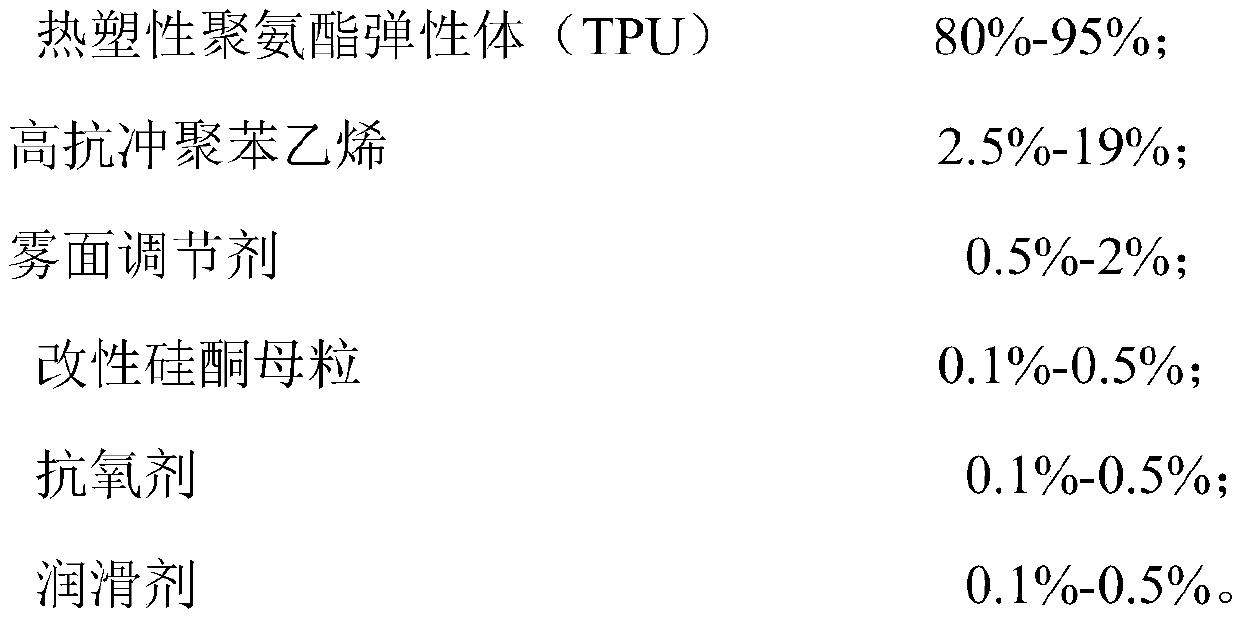

[0031] The raw materials involved in Examples 1~6 and Comparative Examples 1~2 are as follows:

[0032] TPU is 85A polyether TPU and polyester TPU of Huafon Thermoplastic Polyurethane Co., Ltd.;

[0033] High-impact polystyrene is Dushanzi's HIE-1;

[0034] The matte conditioner is high-density polyethylene;

[0035] The modified silicone masterbatch is TPU-based silicone masterbatch, and the product of Dow Corning Company's brand MB50-004 is used;

[0036] The antioxidant is tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, and the trade name is Klein antioxidant 1010;

[0037] The lubricant is a 1:2 (weight ratio) mixture of EBS and E wax;

[0038] The matte conditioner is montmorillonite.

[0039] Each component and mass percent in Examples 1-6 are shown in Table 1.

[0040] Table 1

[0041]

[0042] Preparation:

[0043] Preparation:

[0044] According to the percentage content shown in Table 1, each component is mixed according ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com