Ultra-light clay and preparation method thereof

A technology of ultra-light clay and formula, which is applied in the field of paper clay, can solve problems such as toxicity, environmental protection controversy, and children's health hazards, and achieve the effect of firm cross-linking, high reactivity, and good stability of clusters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

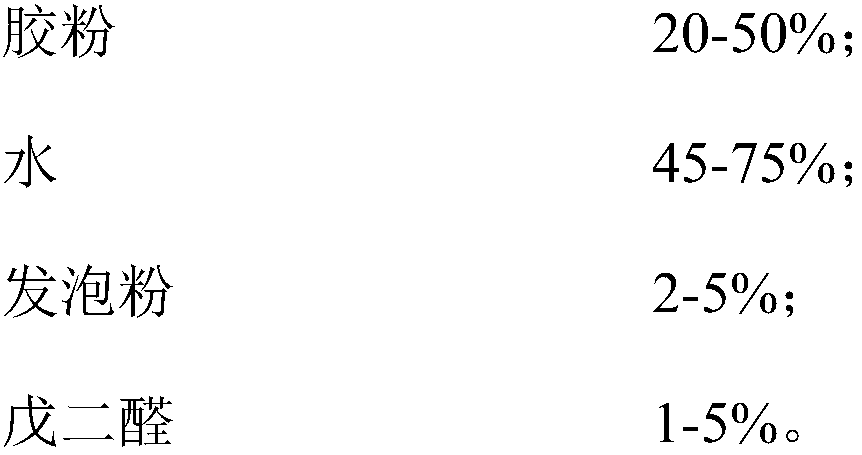

[0040] A kind of ultra-light clay, by mass percentage, its preparation raw material comprises:

[0041]

[0042] Among them, the number average molecular weight of polyvinyl alcohol is 2000.

[0043] The preparation method of above-mentioned ultralight clay comprises the steps:

[0044] (1) Water and glutaraldehyde of formula quantity are added in mixer, mix 5min under the stirring rate of 200r / min, obtain the first mixed material;

[0045] (2) Add the foaming powder of formula quantity in above-mentioned mixer, mix 10min with above-mentioned first mixed material at the stirring speed of 200r / min, obtain the second mixed material;

[0046] (3) Continue to add the rubber powder of formula quantity in above-mentioned mixer, mix 60min with above-mentioned second mixed material at the stirring speed of 200r / min, obtain above-mentioned ultra-light clay.

[0047] Compared with the traditional boron-containing ultra-light clay, the ultra-light clay provided in this example is no...

Embodiment 2

[0049] A kind of ultra-light clay, by mass percentage, its preparation raw material comprises:

[0050]

[0051] Among them, the number average molecular weight of polyvinyl alcohol is 5000.

[0052] The preparation method of above-mentioned ultralight clay comprises the steps:

[0053](1) Add the water and glutaraldehyde of formula quantity in mixer, mix 10min under the stirring speed of 300r / min, obtain the first mixed material;

[0054] (2) Add the foaming powder of formula quantity in above-mentioned mixer, mix 5min with above-mentioned first mixed material at the stirring speed of 300r / min, obtain the second mixed material;

[0055] (3) Continue to add the rubber powder of formula quantity in above-mentioned mixer, mix 30min with above-mentioned second mixed material at the stirring speed of 300r / min, obtain above-mentioned ultra-light clay.

[0056] Compared with the traditional boron-containing ultra-light clay, the ultra-light clay provided in this example is non-...

Embodiment 3

[0058] A kind of ultra-light clay, by mass percentage, its preparation raw material comprises:

[0059]

[0060] Among them, the number average molecular weight of polyvinyl alcohol is 2500.

[0061] The preparation method of above-mentioned ultralight clay comprises the steps:

[0062] (1) Add the water, glutaraldehyde and antifungal agent of formula quantity in the mixer, mix 8min under the stirring speed of 350r / min, obtain the first mixed material;

[0063] (2) Add the foaming powder of formula quantity in above-mentioned mixer, mix 10min with above-mentioned first mixed material at the stirring speed of 350r / min, obtain the second mixed material;

[0064] (3) Continue to add the rubber powder of formula quantity in above-mentioned mixer, mix 40min with above-mentioned second mixed material at the stirring speed of 350r / min, obtain above-mentioned ultra-light clay.

[0065] Compared with the traditional boron-containing ultra-light clay, the ultra-light clay provided ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com