A method for continuous chromatographic separation of tocopherol monomers

A continuous chromatography and tocopherol technology, applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc., to achieve stable performance, meet the requirements of large-scale continuous production, and high feasibility of industrial scale-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] In the present invention, the method for preparing the raw material liquid of the crude mixed tocopherol product may include: mixing the crude mixed tocopherol product with solvent I.

[0024] In the present invention, the ratio of the crude mixed tocopherol product to the solvent I is not particularly limited, and can be a conventional choice in the art. For example, relative to 1 kg of mixed tocopherols, the amount of solvent I can be 0.5-10 L, preferably 0.8-5 L.

[0025] In the present invention, the type of the solvent I can be a conventional choice in the art, for example, the solvent I can be methanol, ethanol, n-propanol, isopropanol, propenol, acetone, hexane, ethyl acetate and one or more of petroleum ether, preferably one or more of methanol, ethanol, ethyl acetate and acetone.

[0026] In the present invention, the definition of the crude product of mixed tocopherols can be conventionally understood in the field. For example, the mixed tocopherols may be n...

Embodiment approach

[0036] According to a specific embodiment, the mixed tocopherols contain two tocopherol monomers, α-tocopherol and β / γ-tocopherol, and α-tocopherol is separated in the first elution unit, and the Deunitization separates β / γ-tocopherol. The elution solvent includes elution solvent I used in the first elution unit and elution solvent II used in the second elution unit. The elution solvent I can be at least one of methanol, ethanol, isopropanol, n-propanol, propenol and acetonitrile, and the elution solvent II can be formed by the elution solvent I and acid according to the ratio of 100ml:0-10g The mixture, preferably 100ml: 0-1g, more preferably 100ml: 0.01-1g. Preferably, the elution solvent I is different from the washing solvent and solvent I. The number of chromatographic columns in the first elution unit and the second elution unit is not particularly limited, and may be one or more columns each. In order to achieve a better separation effect, preferably, the first eluti...

Embodiment 1

[0070] This example is used to illustrate the method for continuous chromatographic separation of tocopherol monomers provided by the present invention

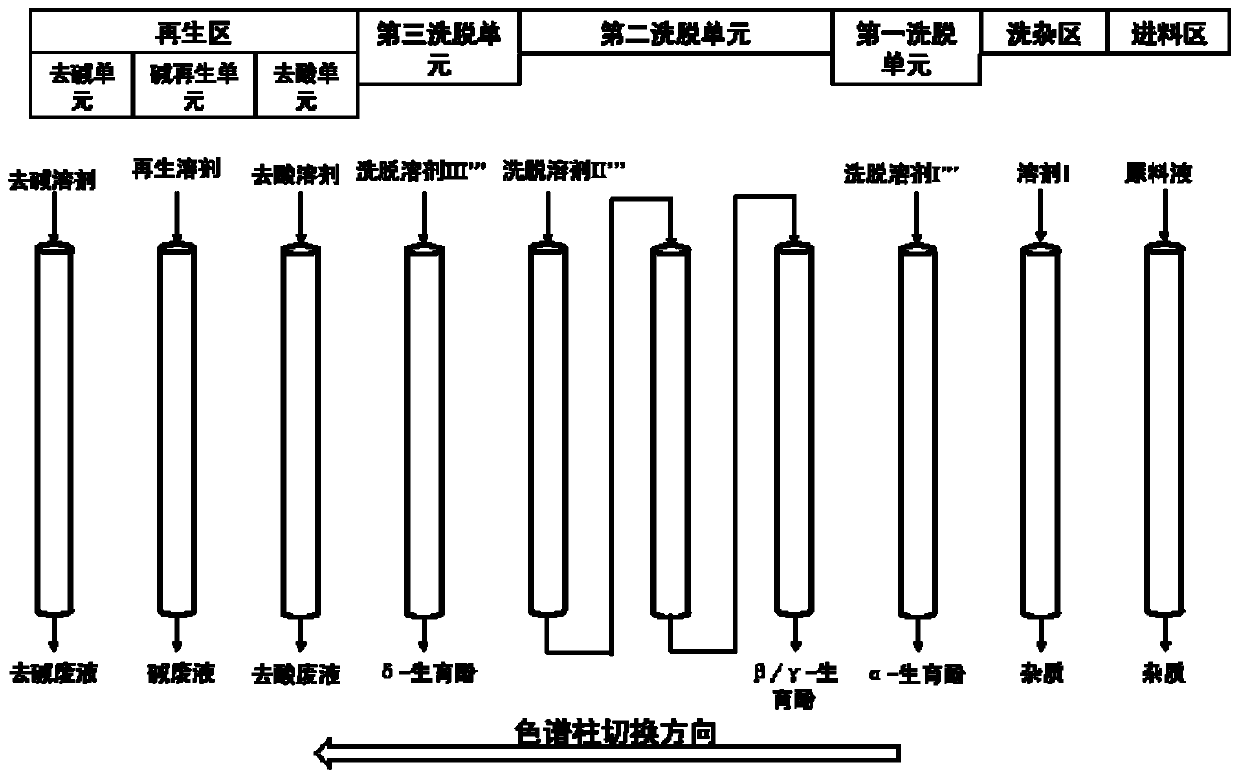

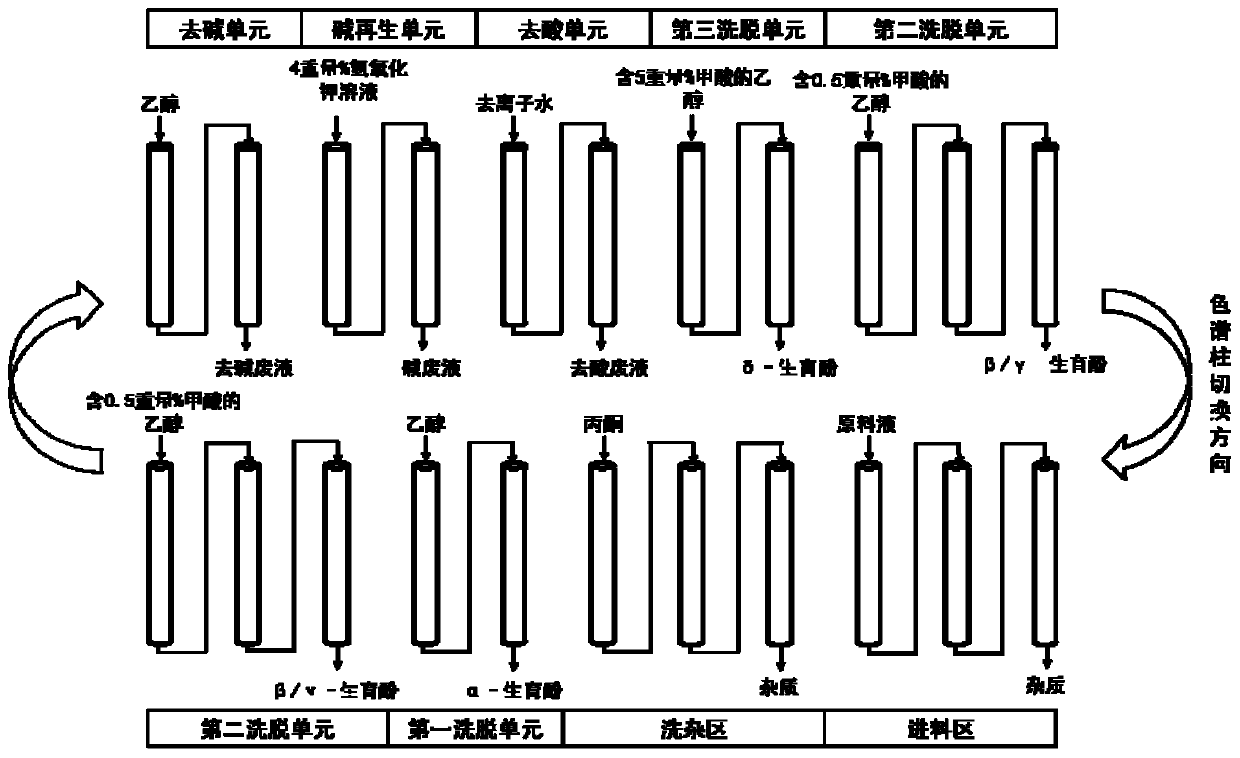

[0071] This embodiment adopts figure 2 The rotary disc type continuous chromatographic separation device of shown 10 post 6 districts (operating area), described continuous chromatogram comprises feeding area (1 chromatographic column), washing impurity area (1 chromatographic column), the first elution unit ( 1 chromatographic column), the second elution unit (3 chromatographic columns, connected in series), the 3rd elution unit (1 chromatographic column) and the regeneration area, the regeneration area includes the acid removal unit (1 chromatographic column), alkali regeneration unit (1 column) and alkali removal unit (1 column). Type I macroporous strong base anion exchange resin is used as the separation medium; the mixed tocopherol crude product used is the mixed tocopherol obtained from vegetable oil deodorization di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com