Low-temperature anaerobic treatment device of high concentration organic wastewater and treatment technology of device

An anaerobic treatment device, a technology for organic wastewater, applied in anaerobic digestion treatment, water/sludge/sewage treatment, water pollutants, etc., to achieve the effects of good growth and renewal, high efficiency, and fast film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

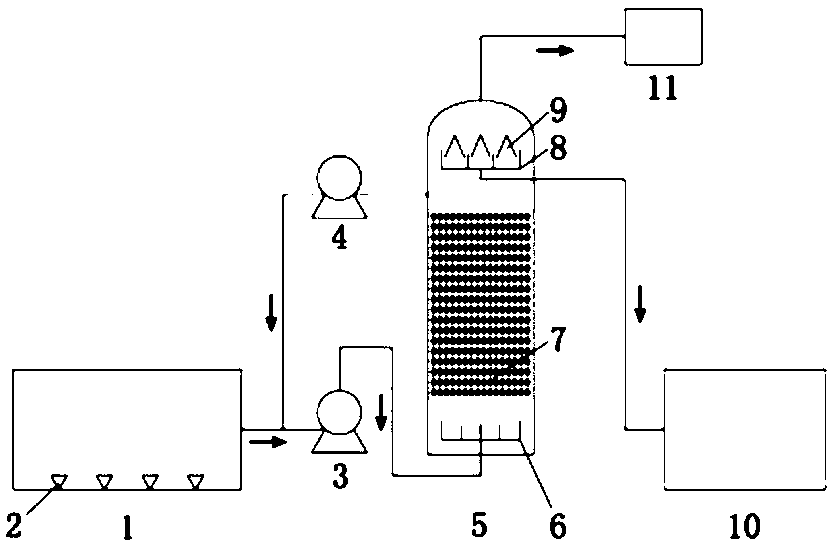

[0036] Embodiment 1: A low-temperature anaerobic treatment device for high-concentration organic wastewater of the present invention includes a pre-conditioning tank 1, a low-temperature anaerobic reactor 5 and a subsequent treatment system 10 connected in sequence. The gas head 2 and the low temperature anaerobic reactor 5 are arranged perpendicular to the bottom of several water distribution pipes 6 to realize the uniform water distribution of the reactor water, and the low temperature anaerobic reactor 5 is evenly filled with polypropylene biological filler 7, and the low temperature anaerobic reactor A water inlet pump 3 is provided on the inlet pipeline of 5, and a reflux pump 4 is provided on the return pipeline;

[0037] The side wall of the pre-regulation tank 1 is connected with a waste water inlet pipe, the side wall of the pre-regulation tank 1 is provided with a sample inlet, and the bottom of the pre-regulation tank 1 is provided with an exposure Gas head, the sid...

Embodiment 2

[0045] The device described in Example 1 was used to treat wastewater from a pharmaceutical company in Hangzhou. The volume of wastewater was 250 tons per day. A low-temperature anaerobic hydrolysis reactor and its treatment process were used. When the influent concentration was 30,000 to 50,000 mg / L, the wastewater The output is 150 tons / day. Through the low-temperature anaerobic treatment device, the COD removal rate of the effluent is as high as 85%, and the BOD / COD is increased from 0.15 to 0.34.

Embodiment 3

[0047] The device described in Example 1 was used to treat a large amount of printing and dyeing wastewater produced by a textile printing and dyeing enterprise. The amount of wastewater was 210 tons per day. The low-temperature anaerobic hydrolysis reactor and its treatment process were used. The influent concentration was 20000~40000 mg / L. When the chroma is 400~600 times, the anaerobic load is 4kgCOD / (m 3 d) When the temperature is between 4 and 25 degrees Celsius 365 days a year, the COD removal rate of the effluent is 40%, the chromaticity removal rate is above 85%, and the BOD / COD is increased from 0.2 to above 0.4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com