Metal pipe cutting device

A cutting device, metal pipe technology, applied in the direction of pipe cutting device, shearing device, positioning device, etc., can solve problems such as damage to equipment, cutting to equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

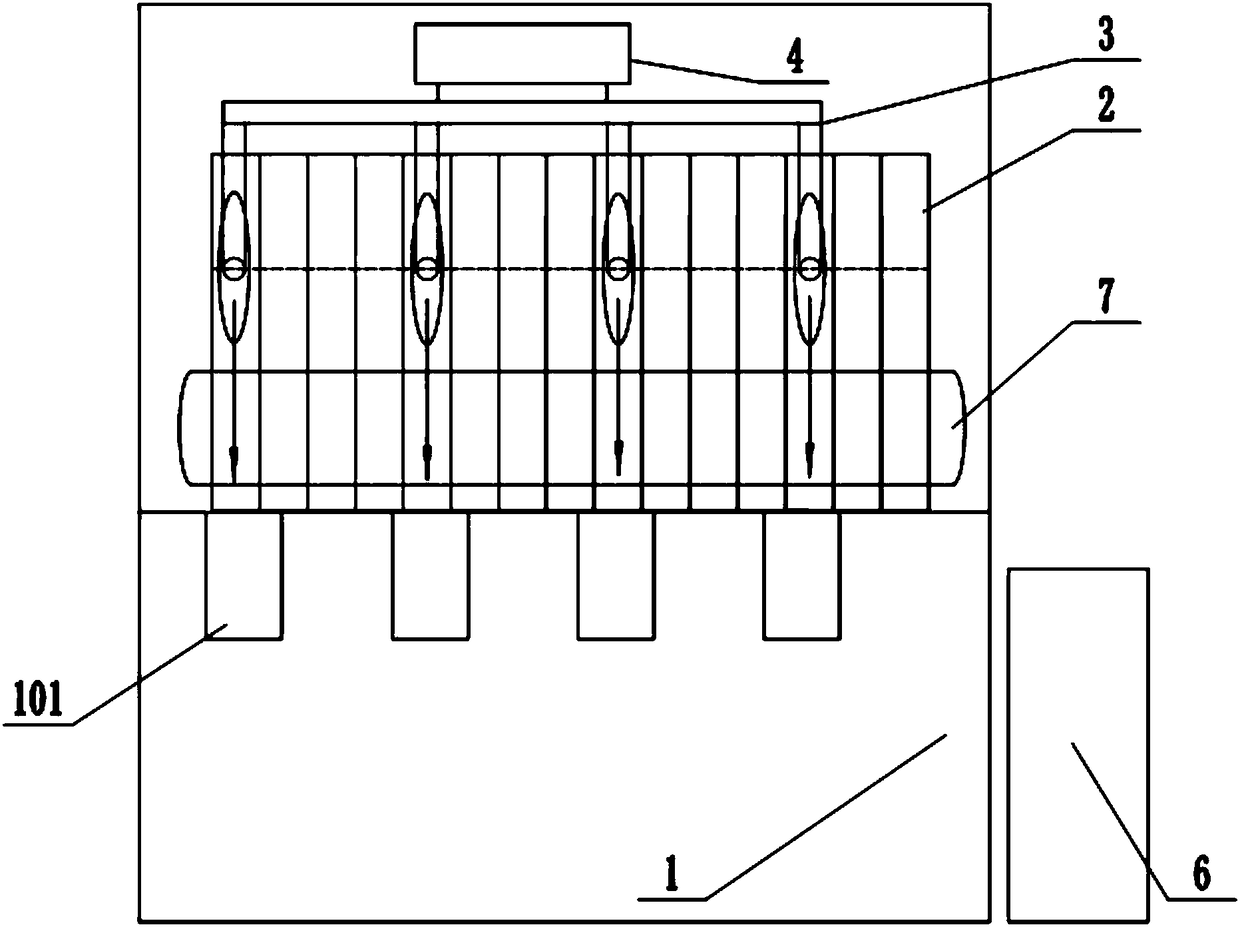

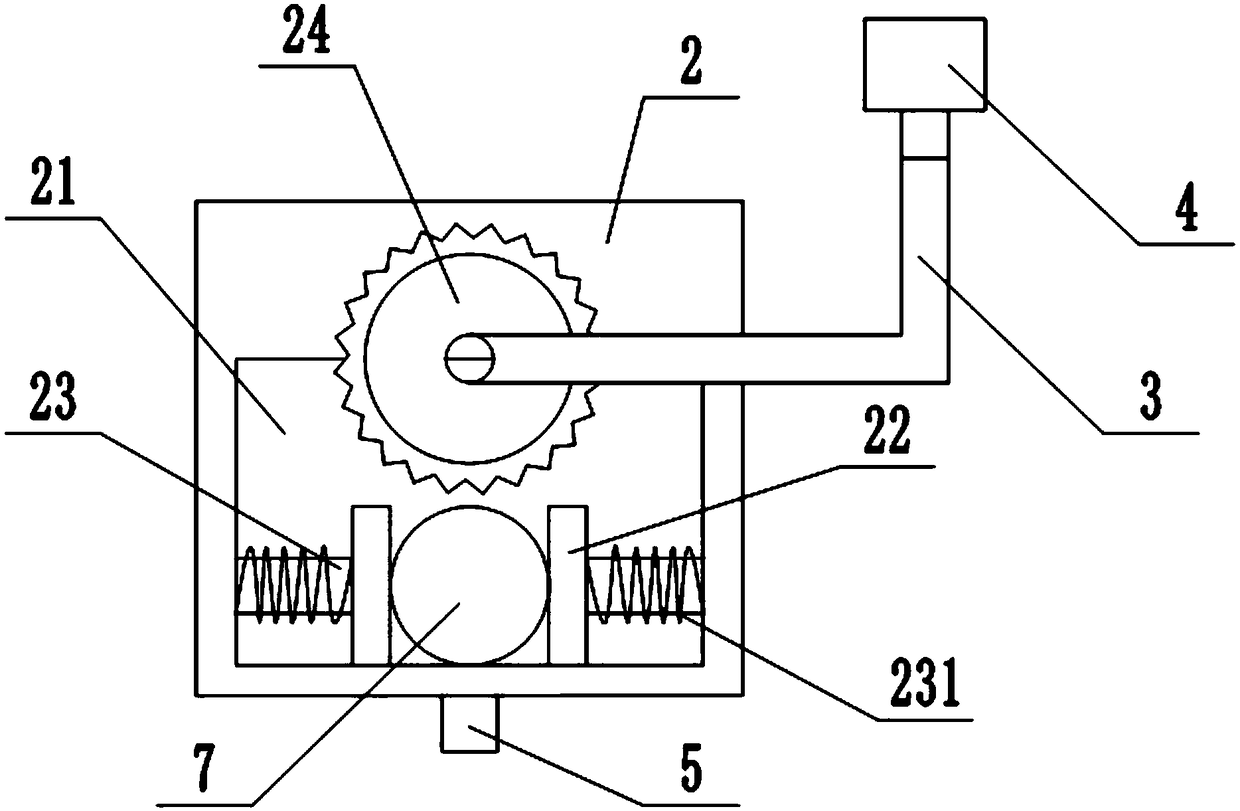

[0018] The reference signs in the accompanying drawings include: cutting base 1, groove 101, plate 2, opening 21, clamp block 22, connecting rod 23, elastic member 231, circular cutter 24, shaft 3, cylinder 4, lift Column 5, receiving box 6, metal pipe 7.

[0019] The embodiment is basically as attached figure 1 , attached figure 2 Shown: a cutting device for a metal pipe 7, including a cutting base 1, the upper surface of the cutting base 1 is provided with a number of evenly distributed grooves 101, the top of the cutting base 1 is provided with closely fitting and neatly arranged Several sheet plates 2, the cutting base 1 is an "L"-shaped base, and the sheet plates 2 are all slidably connected to the inner vertical part of the "L"-shaped cutting base 1, and the sheet plates 2 are provided with Opening 21, the thickness of the sheet 2 is less than the thickness of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com