Denitration catalyst regeneration cyclic utilization method

A denitration catalyst and catalyst technology, which are applied in catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc. Cycle efficiency, ensure catalytic efficiency, and ensure the effect of qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

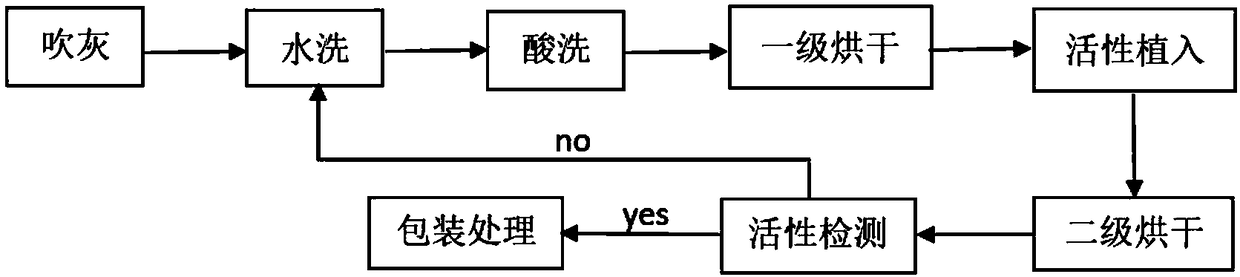

[0028] Such as figure 1 As shown, this embodiment provides a method for denitrification catalyst regeneration and recycling, including:

[0029] Step 1, soot blowing, use a vacuum cleaner to suck off the floating ash on the surface of the catalyst, or use compressed air to blow off the floating ash on the surface of the catalyst;

[0030] Step 2, washing with water, soaking the catalyst in deionized water, and starting ultrasonic cleaning to remove stains on the surface of the catalyst;

[0031] Step 3, pickling, soaking the catalyst in the pickling solution;

[0032] Also includes the following steps:

[0033] Step 4, first-level drying, placing the catalyst in a first-level drying furnace, and performing a first-level drying treatment;

[0034] Step 5, active implantation, immersing the catalyst in the active agent, performing active implantation, realizing activity recovery, and obtaining a regenerated catalyst;

[0035] Step 6, secondary drying, put the regenerated cat...

Embodiment 2

[0044] The difference between this example and Example 1 lies in that the temperature of the primary drying is 320° C. and the drying time is 80 minutes.

Embodiment 3

[0046] The difference between this example and Example 1 is that the secondary drying temperature is 360° C. and the drying time is 100 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com