A garden weeding equipment with gravel cleaning function

A technology of weeding equipment and stone crushing, which is applied in botany equipment and methods, gardening, lawn growth, etc., and can solve the problems of cutting blade damage, high impact of stones, and great harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

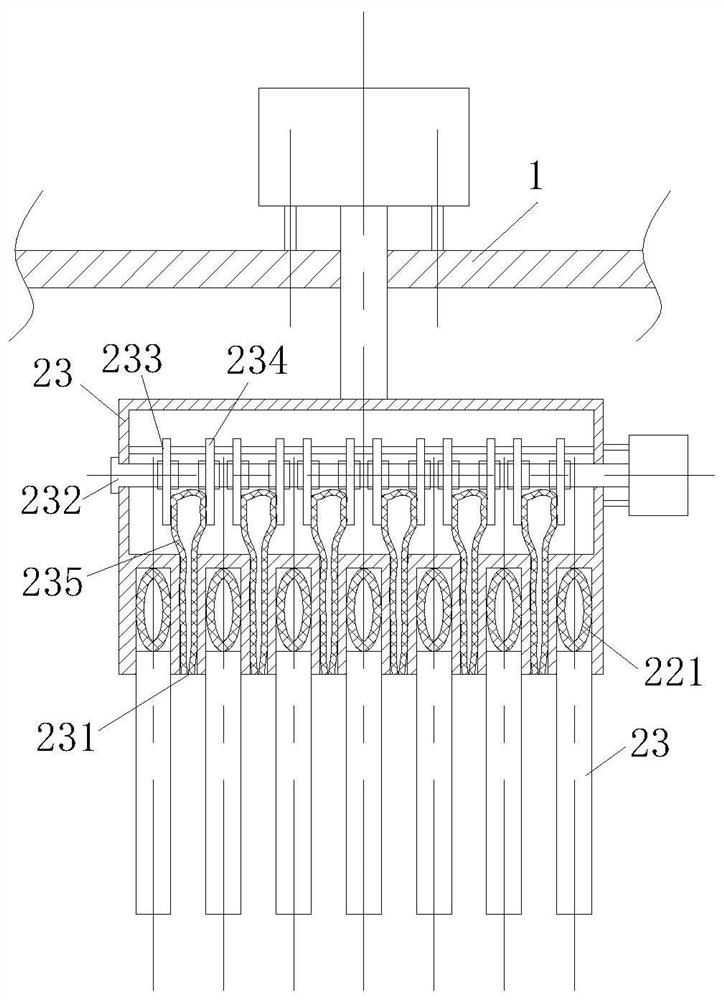

[0030] As an embodiment of the present invention, the lower end of the mounting plate 22 is provided with a set of mounting holes, and a hollow capsule 221 is arranged in the mounting hole; the hollow capsule 221 is oval; the lower end of the hollow capsule 221 is fixedly connected to The comb teeth 23 can be compressed when the ground is undulating when the comb teeth 23 are combing the grass. Through the elasticity of the hollow capsule, the comb teeth can better fit the ground.

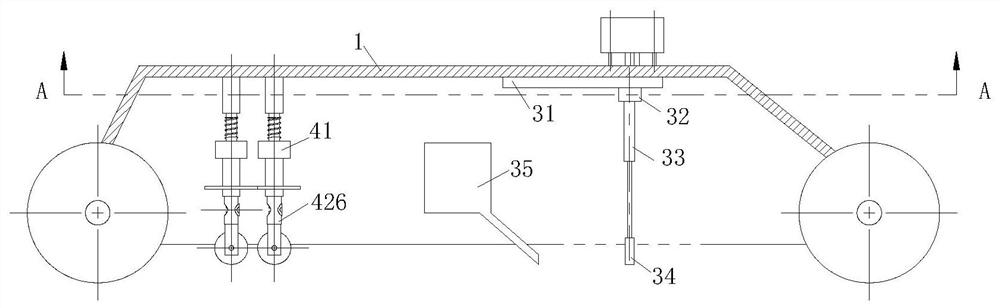

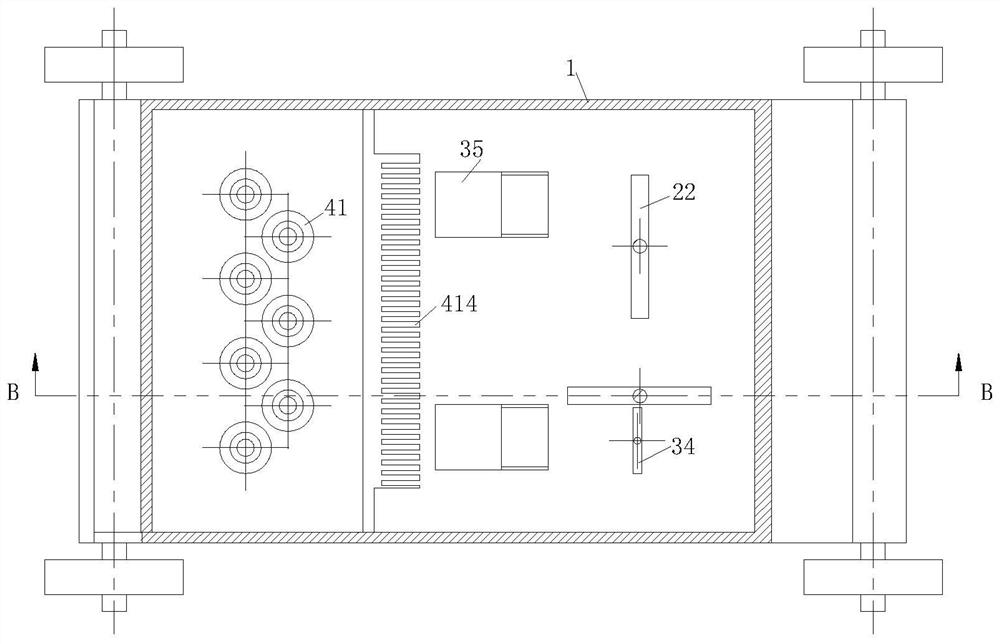

[0031] As an embodiment of the present invention, the cutting module 4 includes a group of cutting units 41; the cutting units 41 are arranged in a staggered manner inside the machine body 1; and wheels 413; the telescopic rod 411 is installed on the upper end of the body 1, one end of the telescopic rod 411 is connected to one end of the cutting motor 415, and the lower end of the cutting motor 415 rotating shaft is fixedly connected to the cutting piece 412; the cutting piece 412 is below Coopera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com