V-shaped radar radome structure and preparation method thereof

A technology of radar radome and radome, which is applied in the field of radome, can solve the problems of not meeting the electrical performance requirements of the "V" structure radome, the distortion of the antenna pattern, and the deterioration of the overall electrical performance. Multi-layer reflection interference, increase the amplitude contrast value, and weaken the effect of interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Paste the quartz fiber reinforced cyanate-based prepreg on the female mold of the radome, wherein the thickness of the quartz fiber is 0.14mm, and the number of layers is 6, and then hot-pressed and cured, the curing system : 80°C / 1h, 160°C / 1h, 180°C / 2h, 200°C / 2h, 230°C / 2h, hold at 180°C for 30 minutes and pressurize at 0.3MPa to obtain a skin with a thickness of 1mm;

[0028] 2) Bonding a cyanate-based adhesive film in the skin, filling the PMI foam into the female mold to obtain the radome structure;

[0029] 3) bonding the cyanate film at the bottom of the above-mentioned PMI foam, and installing an antenna, so that the antenna and the PMI foam are bonded by the cyanate film;

[0030] 4) Vacuum co-curing is carried out on the structure obtained in step 3), and the curing system is 180°C / 3h, and the product is obtained.

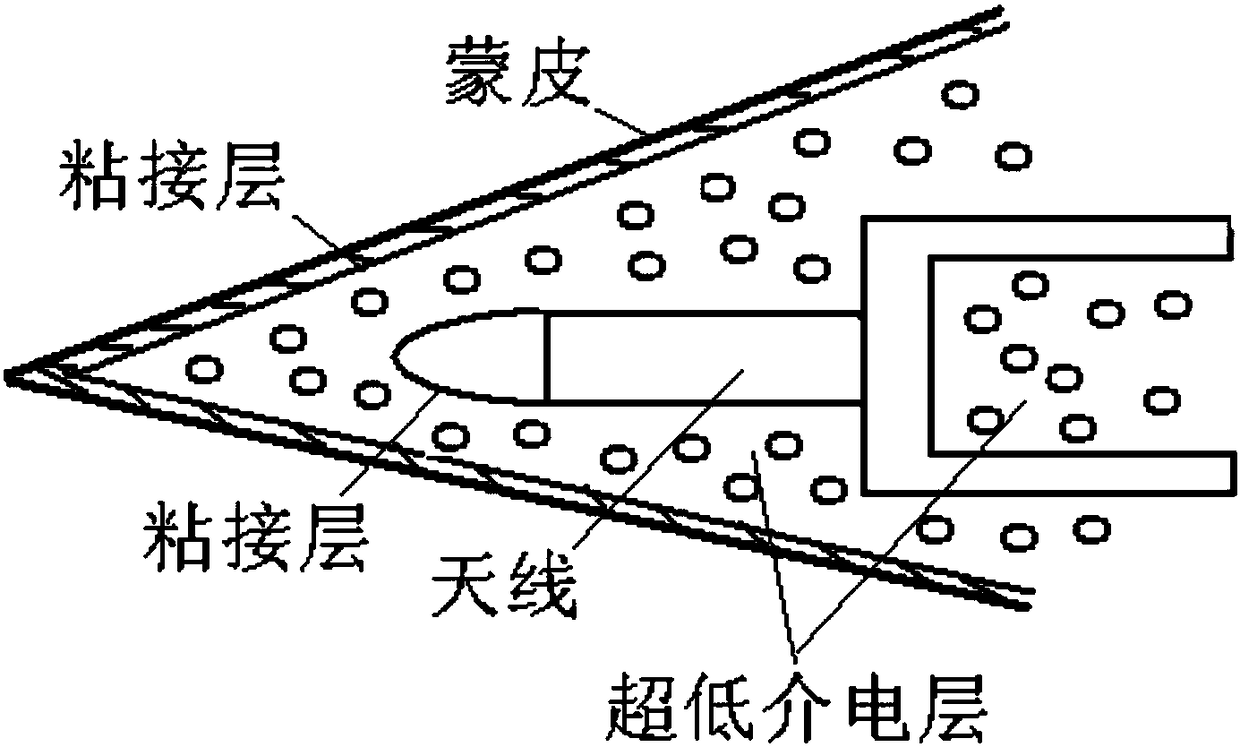

[0031] The obtained "V" type radome structure is as follows figure 1 As shown, the average wave transmission rate in the X and K frequency band...

Embodiment 2

[0033] 1) Paste the quartz fiber reinforced cyanate-based prepreg on the female mold of the radome, wherein the thickness of the quartz fiber is 0.14mm, and the number of paved layers is 9 layers, and then hot-pressed and cured, the curing system : 80°C / 1h, 160°C / 1h, 180°C / 2h, 200°C / 2h, 230°C / 2h, hold at 180°C for 30 minutes and pressurize at 0.3MPa to obtain a skin with a thickness of 1.5mm;

[0034] 2) Bonding a cyanate-based adhesive film in the skin, filling the PMI foam into the female mold to obtain the radome structure;

[0035] 3) bonding the cyanate film at the bottom of the above-mentioned PMI foam, and installing an antenna, so that the antenna and the PMI foam are bonded by the cyanate film;

[0036] 4) Vacuum co-curing is carried out on the structure obtained in step 3), and the curing system is 180°C / 3h, and the product is obtained.

[0037] The obtained "V" type radome structure is as follows figure 1 As shown, the average wave transmission rate in the X and K...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com