Method for improving interface state of back surface of PERC battery and battery prepared by same

A technology of interface state and back surface, applied in the field of solar cells, to achieve the effect of improving passivation effect, improving EL problem and improving EL yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for improving the interface state on the back of a PERC battery, specifically comprising the following steps:

[0036] 1). Pretreatment of the original silicon wafer, the pretreatment includes texturing, diffusion, etching, annealing (thermal oxygen) and other processes in the battery process;

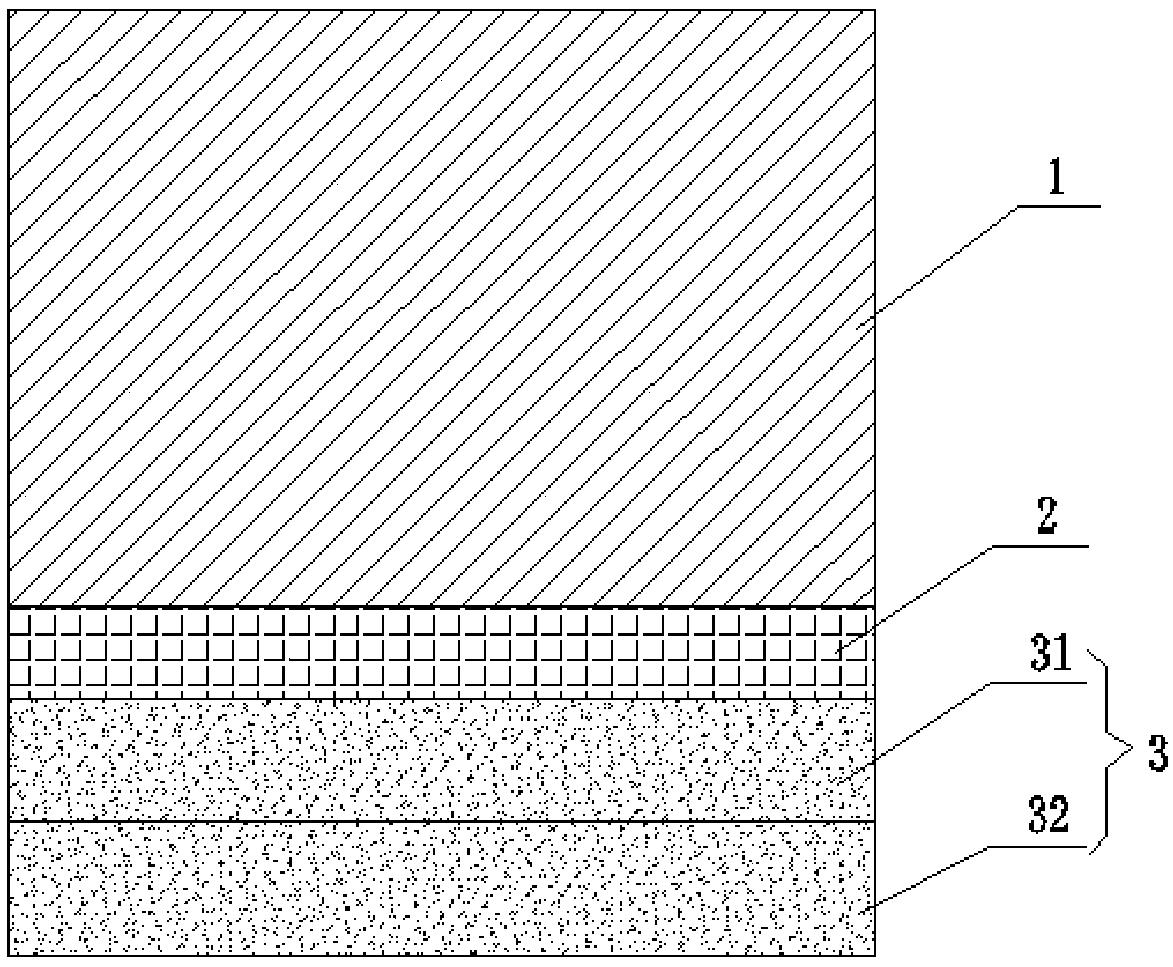

[0037] 2). Use tubular PECVD equipment to clean the surface with plasma on the etched and polished surface, N 2 The O flow rate is 5slm, the discharge power is 4500W, the pulse switch ratio is 6:12, and the continuous discharge time is 300s; then a back passivation film is plated on the back Si layer 1, and the bottom layer is Al 2 o 3 Layer 2, the refractive index is 1.65, and the thickness of the film layer is 10nm, and the bottom layer Al 2 o 3 Layer 2, using TMA and N 2 The mixed gas of O is used as the gas source, the volume ratio of the two is 1:10, and the deposition temperature is 250°C;

[0038] The top layer is a double-layer SiNx layer 3, the first SiNx ...

Embodiment 2

[0041] A method for improving the interface state of the PERC battery back, comprising the following steps:

[0042] 1). Pretreatment of the original silicon wafer, the pretreatment includes texturing, diffusion, etching, annealing (thermal oxygen) and other processes in the battery process;

[0043] 2). Use tubular PECVD equipment to clean the surface with plasma on the etched and polished surface, N 2 O flow rate 5slm, discharge power 6500W, pulse switch ratio 6:18, continuous discharge time 500s; then plate the back passivation film layer, the bottom layer is Al 2 o 3 Layer 2, the refractive index is 1.65, the film thickness is 12nm, and the bottom layer Al is deposited 2 o 3 Layer 2, using TMA and N 2 The mixed gas of O is used as the gas source, the volume ratio of the two is 1:20, and the deposition temperature is 500°C;

[0044] The top layer is a double-layer SiNx layer 3, the first SiNx layer 31 has a refractive index of 2.15 and a film thickness of 25nm, and the s...

Embodiment 3

[0047] A method for improving the interface state on the back of a PERC battery, specifically comprising the following steps:

[0048] 1). Pretreatment of the original silicon wafer, the pretreatment includes texturing, diffusion, etching, annealing (thermal oxygen) and other processes in the battery process;

[0049] 2). Use tubular PECVD equipment to clean the surface with plasma on the etched and polished surface, N 2 The O flow rate is 5slm, the discharge power is 7500W, the pulse switch ratio is 6:12, and the continuous discharge time is 500s; then a back passivation film is plated on the back Si layer 1, and the bottom layer is Al 2 o 3 Layer 2, the refractive index is 1.65, the thickness of the film layer is 20nm, and the bottom layer Al is deposited 2 o 3 Layer 2, using TMA and N 2 The mixed gas of O is used as the gas source, the volume ratio of the two is 1:15, and the deposition temperature is 350°C;

[0050] The top layer is a double-layer SiNx layer 3. The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com