Intelligent sensitive plate temperature modeling method based on mixed elite captivity optimization

A modeling method and sensitive board technology, applied in the direction of instrument, adaptive control, control/regulation system, etc., can solve the problems of complex mechanism, lag, destroying system stability, etc., to achieve clear physical meaning, few parameters, and prevent falling into local optimum effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

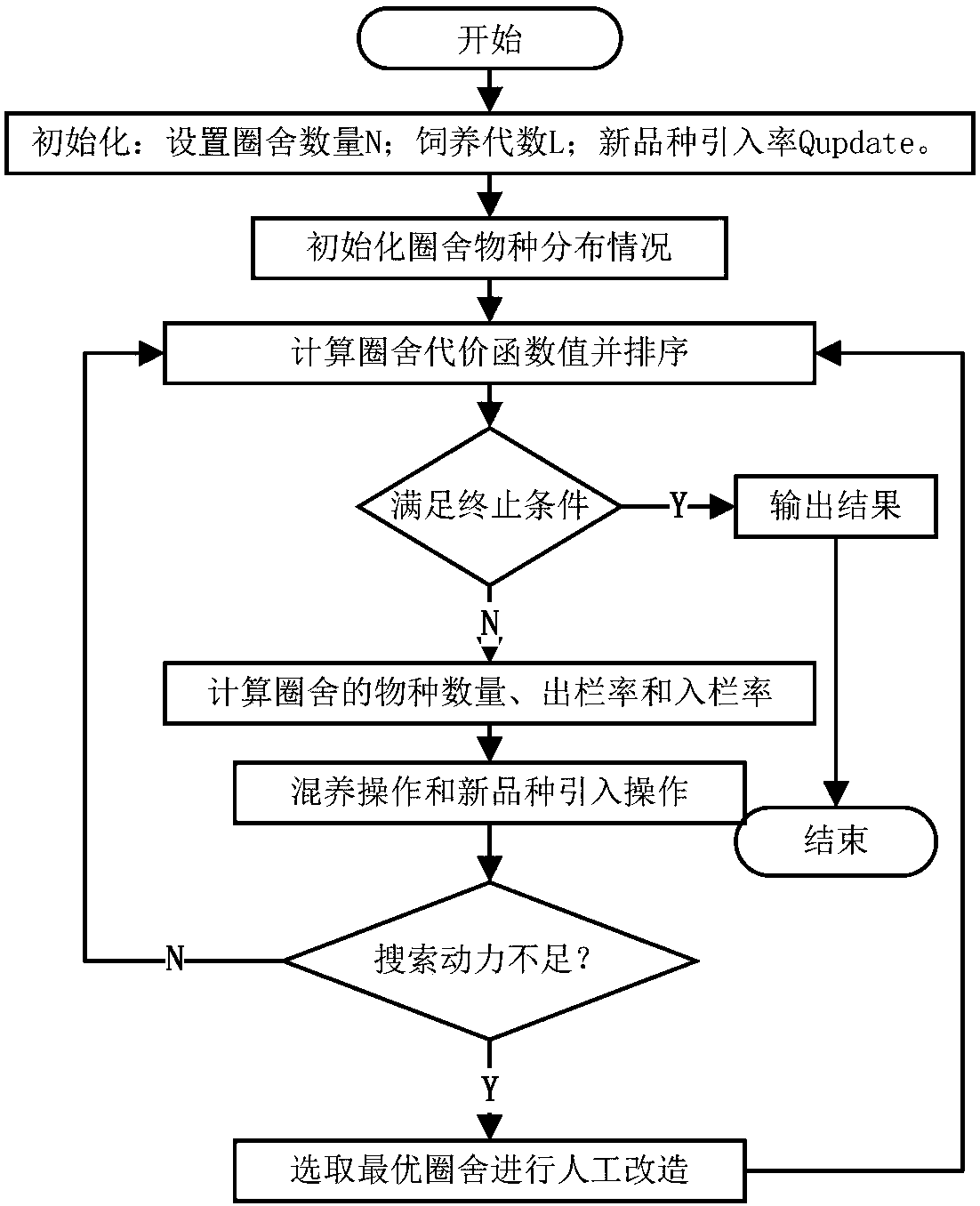

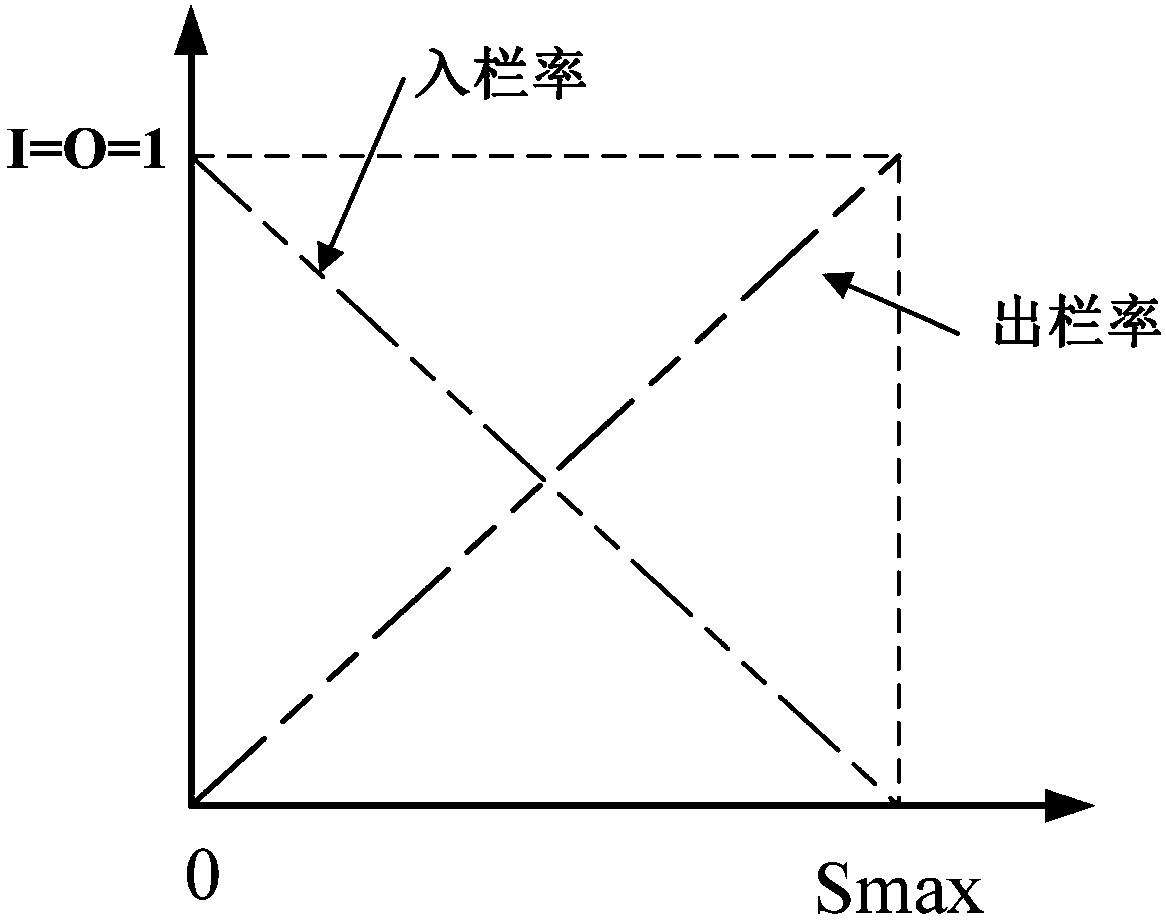

Method used

Image

Examples

Embodiment Construction

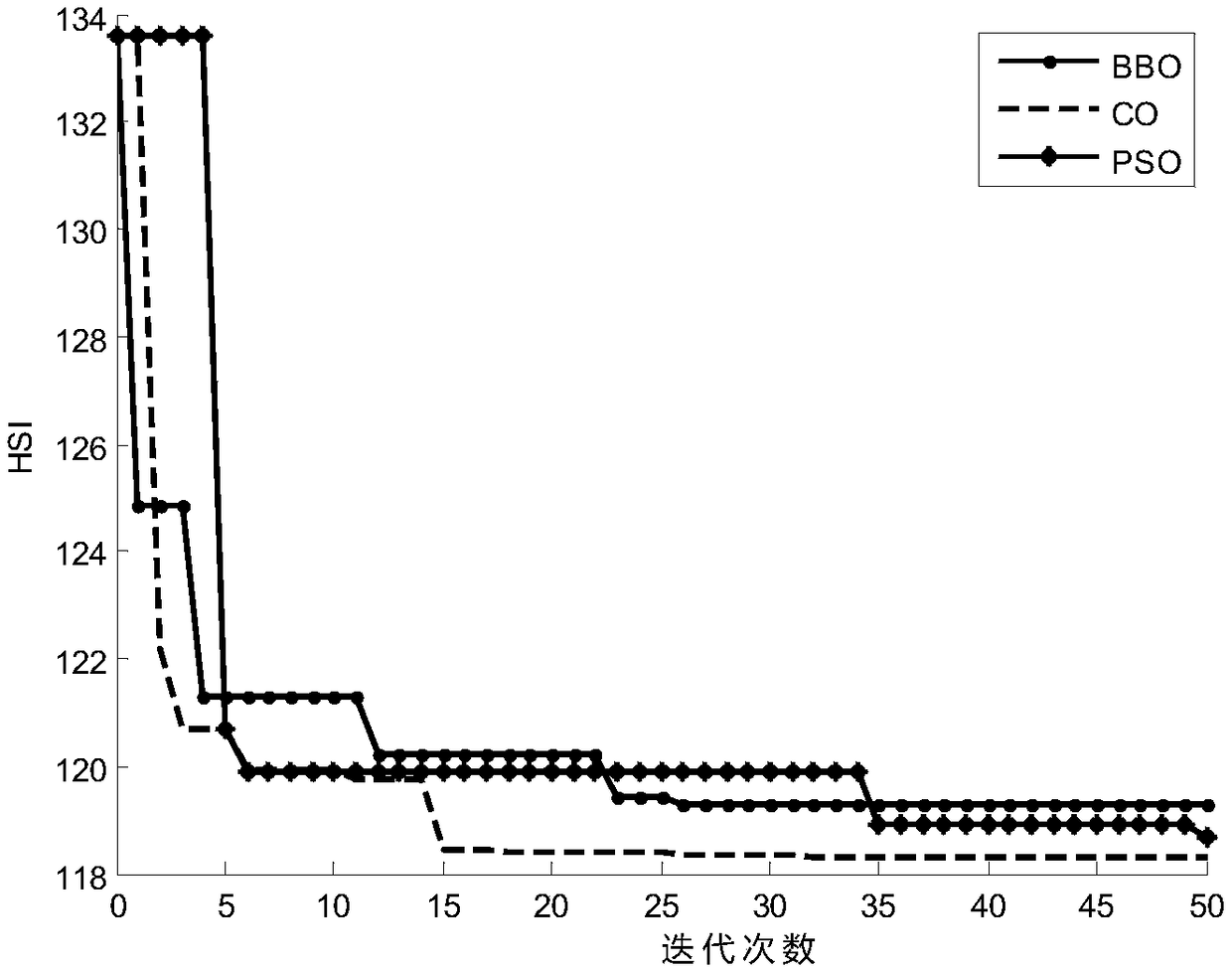

[0038] In order to verify the effectiveness of the above scheme and facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be explained and understood that the implementation examples described here are only used to illustrate and explain the present invention. It is not intended to limit the invention.

[0039] The invention takes the modeling of the temperature control loop of the sensitive plate of the rectification tower in the chemical process industry as an example to verify the effect of the hybrid elite captive breeding optimization algorithm in the first-order plus-purity hysteresis system model identification method.

[0040] The model of the controlled object is:

[0041]

[0042] The model of the controller is:

[0043]

[0044] Among them: K p =0.218, T i =0.138, T d =0. Give the system a step response, and add a wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com