A low-temperature rapid blasting device

A fast, low-temperature technology, applied in blasting and other directions, can solve problems such as abnormal blasting, physical impact of workers, and easy dust, and achieve the effect of solving safety problems, improving work efficiency, and improving filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

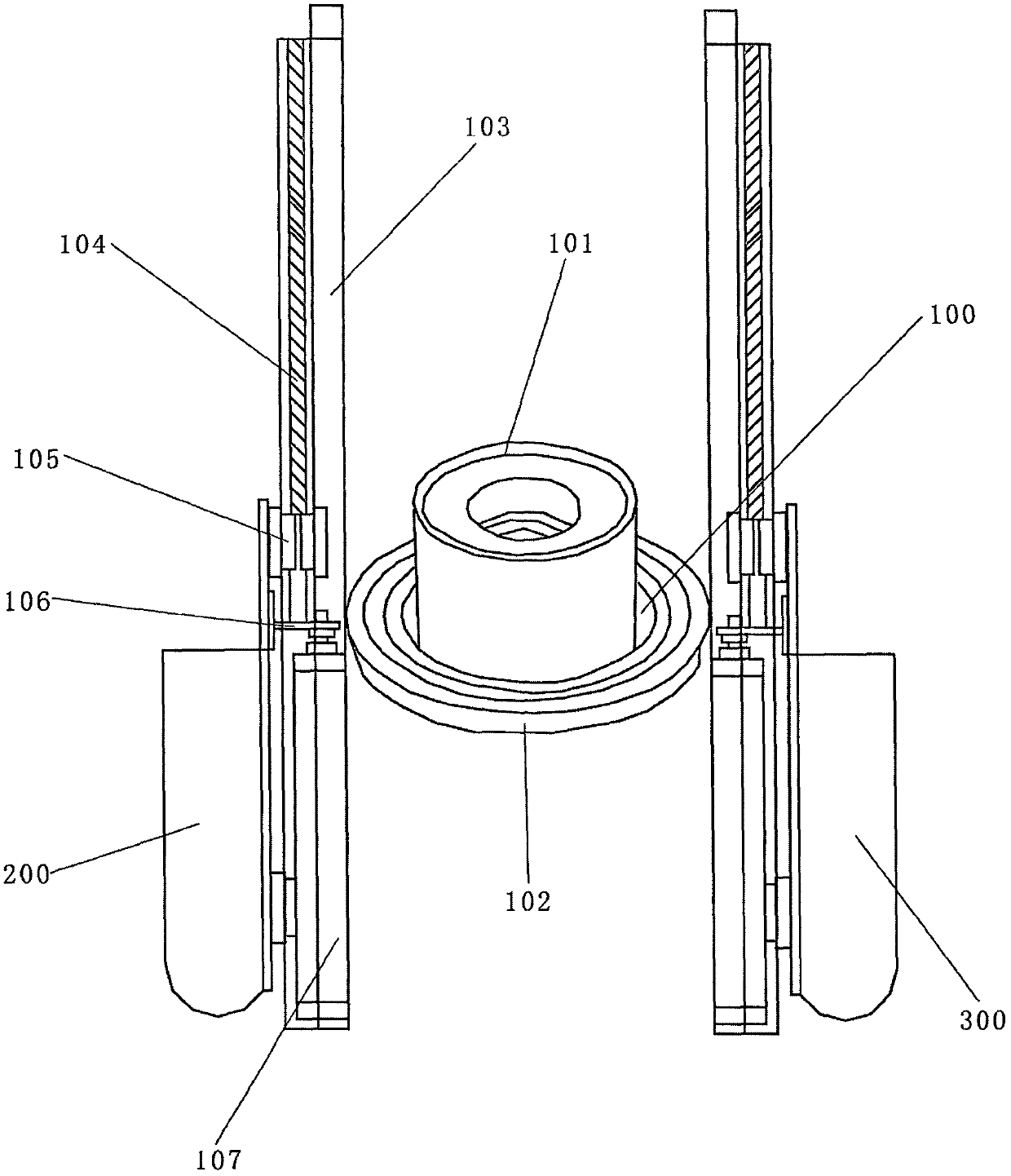

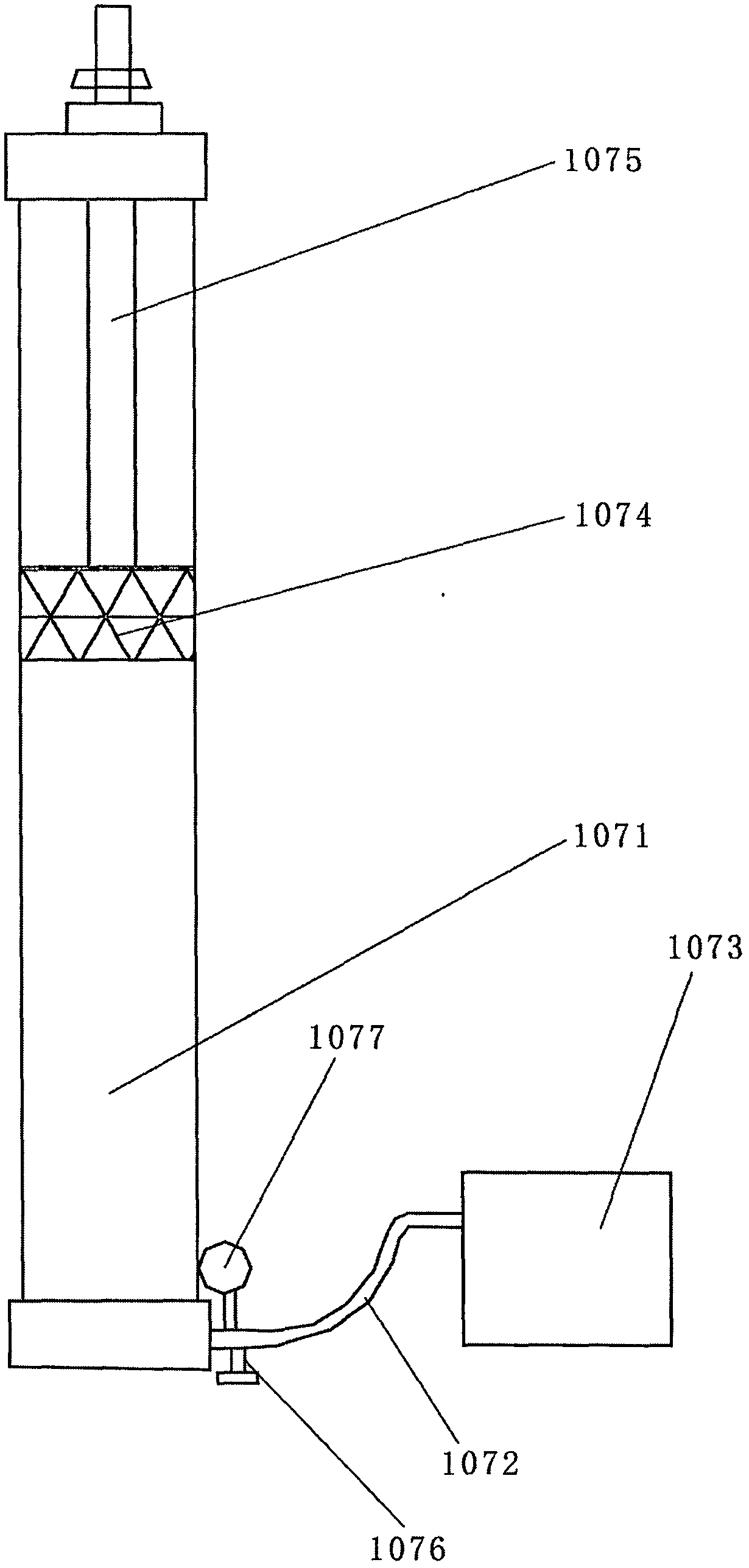

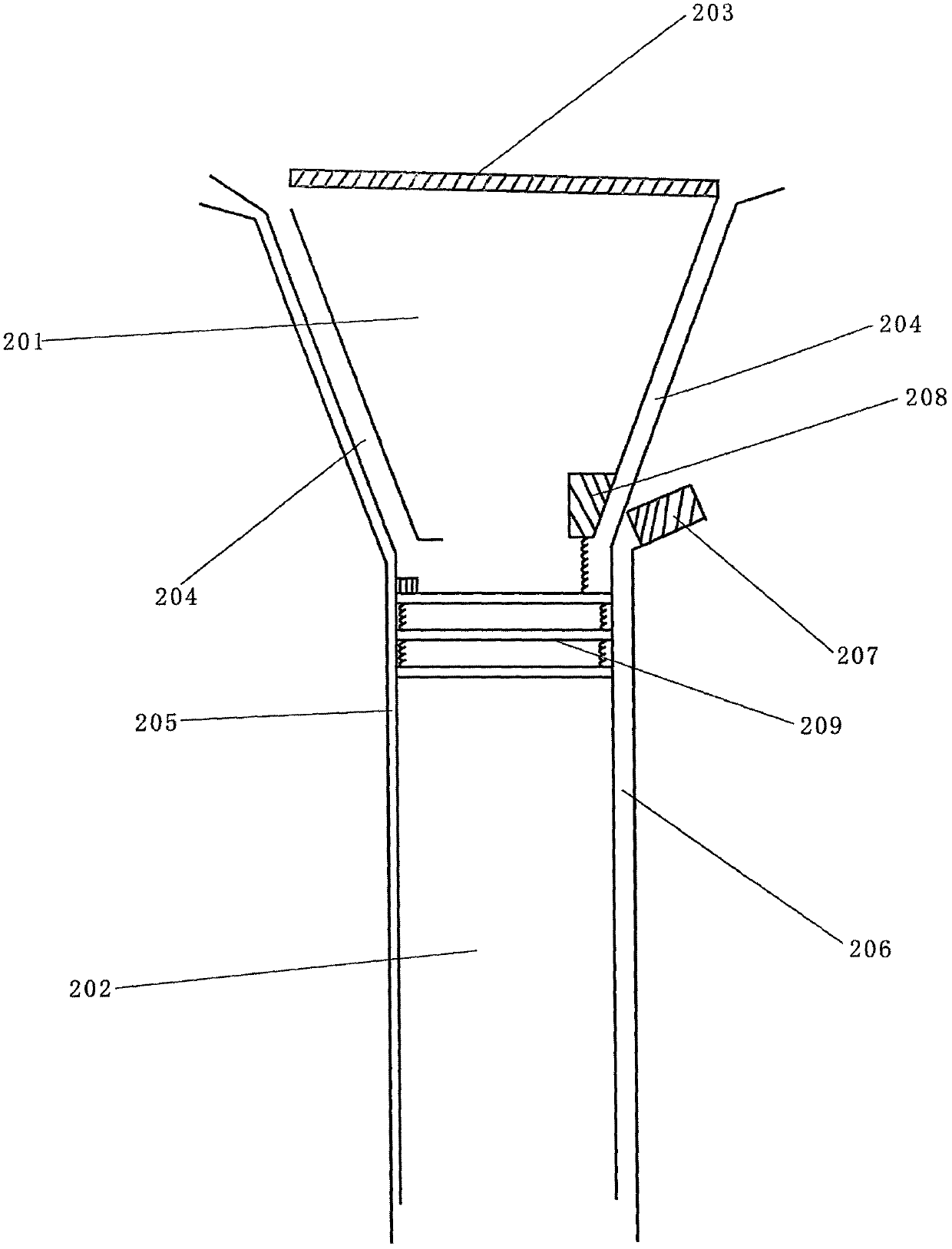

[0050] Such as figure 1 , 3 , 7, a low-temperature rapid blasting device, including power and master control device, rapid cooling perforation device 300, rapid charging device 200 and pneumatic lifting device 100. The device is an integrated device for automatic drilling, charging, and blasting. It can not only achieve rapid drilling during the drilling process, but also achieve uniform and continuous cooling of the drill bit and blasting holes, improve the discharge efficiency of excavated objects, and ensure pollution-free drilling. At the same time, it can improve the filling efficiency of the powder during the charging process, prevent the agglomerated powder from blocking the blast hole, ensure the safety of the staff, avoid waste in the powder filling process, further ensure the blasting safety and blasting effect, and improve the blasting operation. efficiency.

[0051] Such as figure 1 As shown, the pneumatic lifting device 100 of the present invention includes a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com