Boiling waste steam waste heat recycling device

A waste heat recovery device and waste steam recovery technology, applied in steam/steam condensers, lighting and heating equipment, sustainable manufacturing/processing, etc., can solve the problems of large energy waste, difficult independent recovery, small pots, etc. Achieve the effect of reducing water waste, eliminating food odor, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

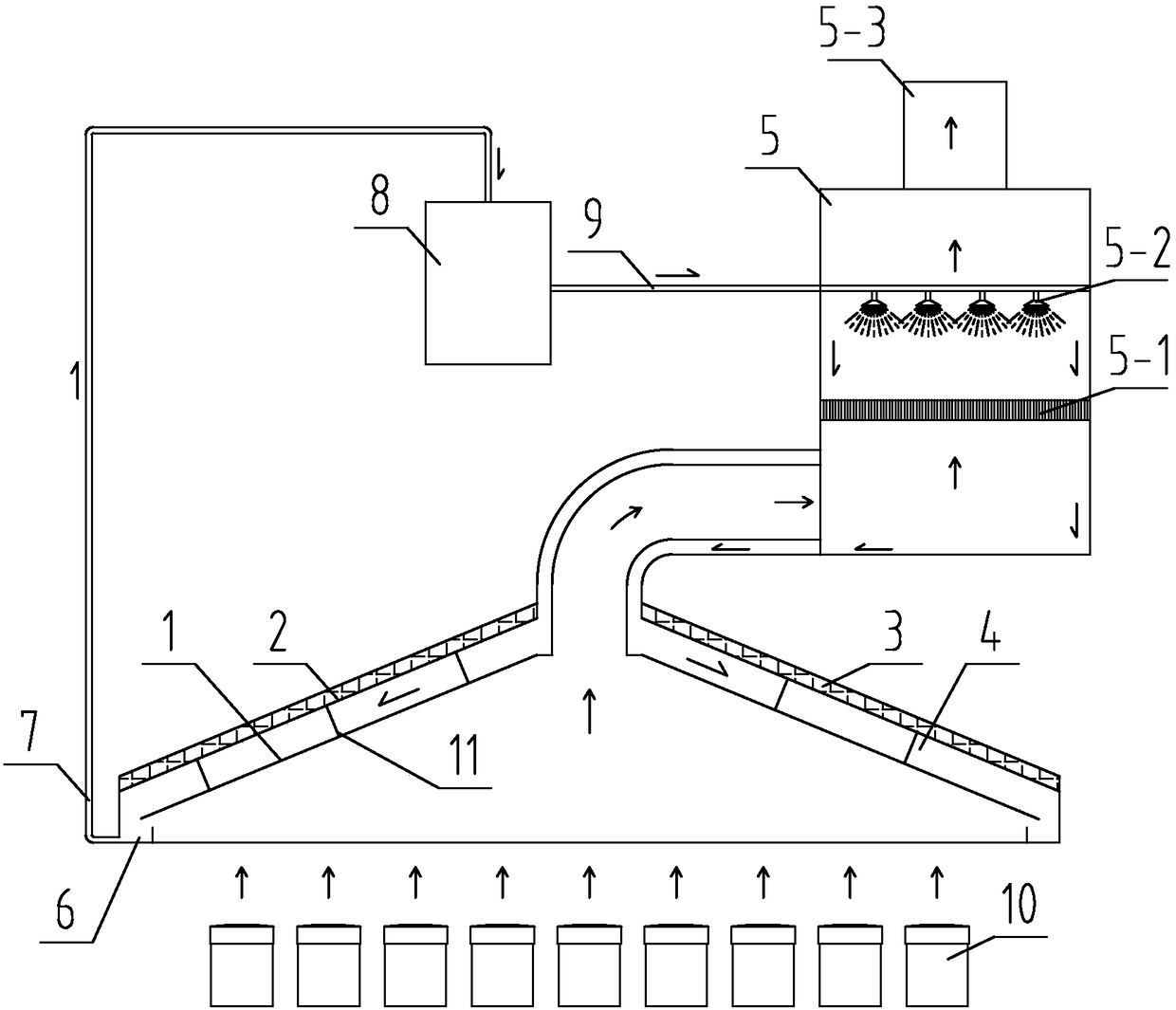

[0022] The heat exchange inner cover 1 is combined with the heat exchange outer cover 2. The cover body is tapered, and a cavity is formed in the cover. The spiral flow channel partition plate 11 is welded in the cavity, and the spiral heat exchange flow channel 4 is paralleled to pass through the exhaust steam recovery device. 5. The recovered heat flows through the entire heat exchange cover along the spiral heat exchange channel 4, and finally flows into the recovery tank 6 at the bottom of the recovery cover after being heated. After passing through the recovery pipe 7, the recovered heat is sent to the recovery heat for use In the workshop 8, the water is transported to the spray head 5-2 through the spray water delivery pipeline 9 after cooling down.

[0023] The waste steam recovery device 5 is composed of a spray bed 5-1, a spray head 5-2, and an exhaust port 5-3, and performs a spray condensation heat exchange on the exhaust steam that is not condensed from the heat ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com