Compound cylinder for controlling lifting of winding cradleofspinning machine

A technology for spinning machines and cylinders, which is applied in spinning machines, continuous winding spinning machines, textiles and papermaking, etc. It can solve the problems of not ensuring the tightness of yarns, reducing the operating efficiency of machines, and poor working performance. Stability and other issues, to achieve the effect of moderate degree of tightness, high working stability and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

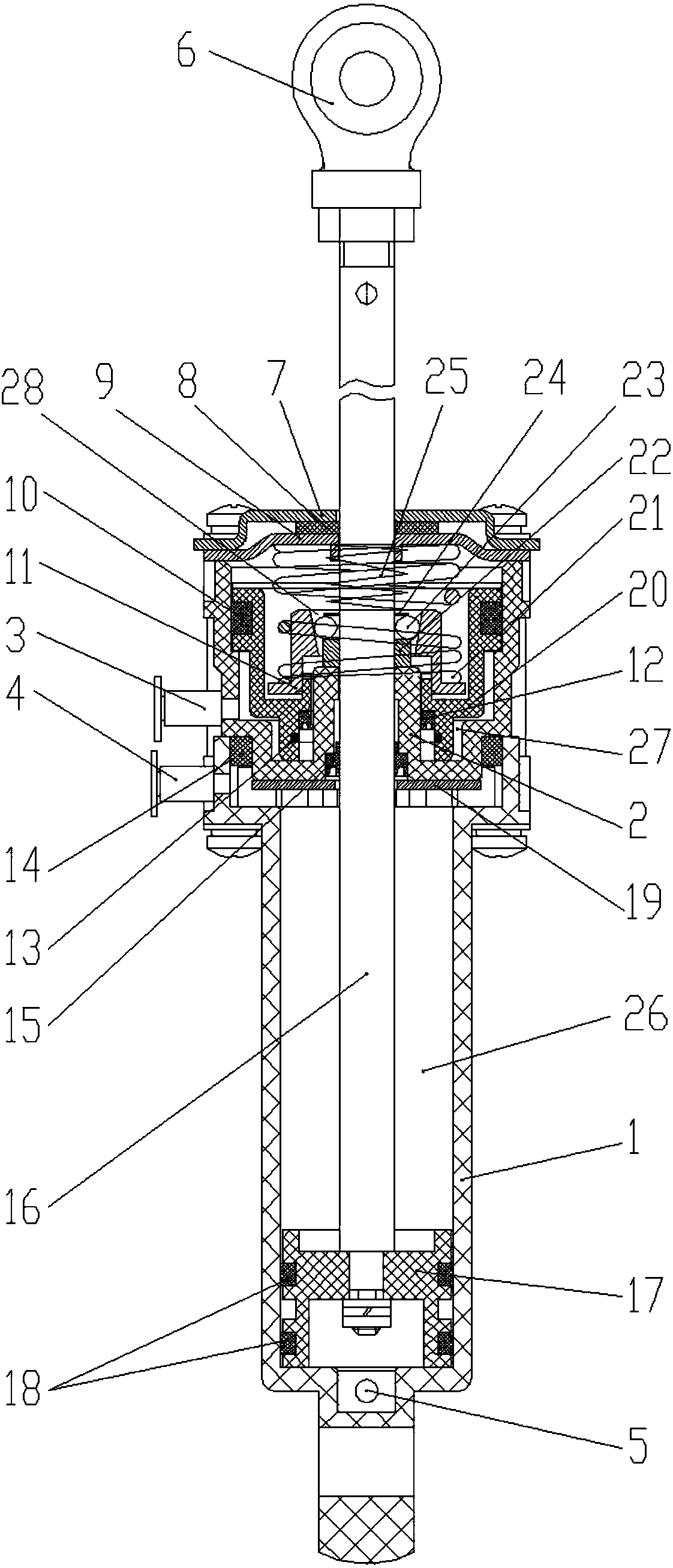

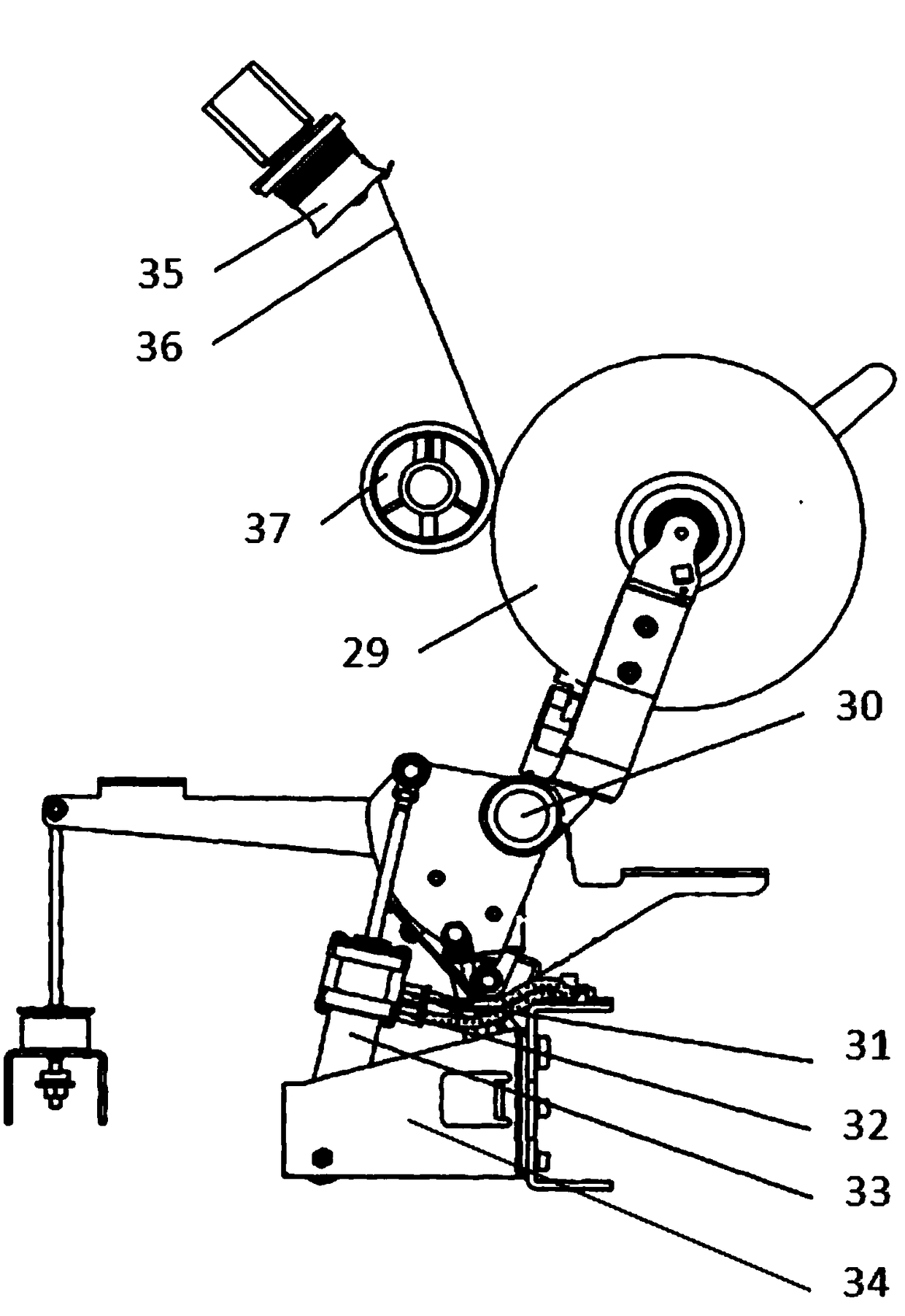

[0017] Attached below Figure 1-2 Embodiments of the present invention are described.

[0018] Composite cylinders used to control the lifting of the winding cradle of spinning machines, such as figure 1 As shown, it includes a large cylinder 1, a small cylinder 2 and a piston rod 16. The bottom of the large cylinder 1 is provided with a muffler 5, and the upper end of the large cylinder 1 is sealed with the lower end of the small cylinder 2. Wherein, the large cylinder The upper end of 1 and the lower end of small cylinder 2 are provided with gasket I19, and the upper end of large cylinder 1 and the lower end of small cylinder 2 are sealed and connected by Y-shaped sealing ring III14, so that the inner cavity of large cylinder 1 and the inner cavity of small cylinder 2 are not connected to each other . The upper end of the small cylinder 2 is covered by a gland plate assembly, specifically, the gland plate assembly includes a pressure plate 7 and a cover plate 9, the cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com