Millstone pressing method of puer tea

A technology of Pu'er tea and stone grinding, applied in the field of Pu'er tea pressing, can solve the problems of complicated operation, inconsistent taste, uneven density, etc., and achieve the effect of uniform spatial density, moderate tightness, and consistent taste of tea soup.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

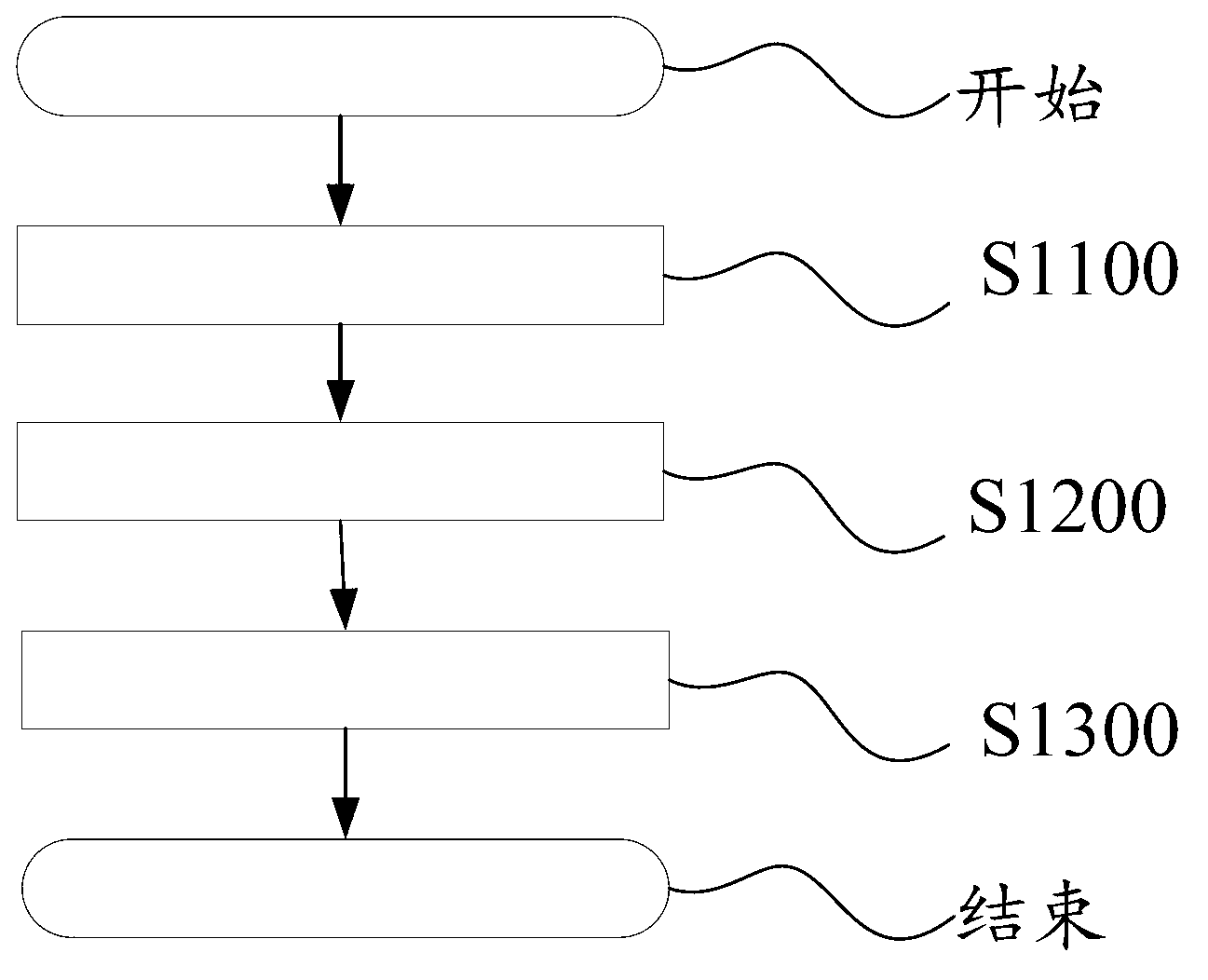

[0023] According to an embodiment of the present invention, the stone mill pressing method of Pu'er tea is carried out in the following steps: first carry out S1100 weight loading step: weigh 357 grams of dry raw tea into a cylinder and fumigate in steam, and dissolve the tea after steaming Put the tea gel into a cloth bag, knead it into a round cake, put it under the stone mill, and load a weight of 45 kg vertically on the stone mill. The diameter of the stone mill is 33cm, the thickness of the stone mill is 15cm, and the weight of the stone mill is 29Kg ; Then carry out the S1200 peripheral pressing step, press the weight-loaded dry raw tea along the outer periphery of the stone mill, press 4 times on the front, back, left, and right sides of the stone mill, and then shake clockwise for a circle; finally enter the S1300 middle pressing step: carry out the middle The pressed dry raw tea is pressed once in the middle of the stone mill; the entire pressing process takes 1 minute...

Embodiment 2

[0025] According to an embodiment of the present invention, the stone mill pressing method of Pu'er tea is carried out in the following steps: first carry out S1100 weight loading step: weigh 357 grams of dry raw tea into a cylinder and fumigate in steam, and dissolve the tea after steaming Put the tea gel into a cloth bag, knead it into a round cake, put it under the stone mill, and load a weight of 45 kg vertically on the stone mill. The diameter of the stone mill is 34cm, the thickness of the stone mill is 16cm, and the weight of the stone mill is 31Kg ; Then carry out the S1200 peripheral pressing step, press the weight-loaded dry raw tea along the outer periphery of the stone mill, press 4 times on the front, back, left, and right sides of the stone mill, and then shake clockwise for a circle; finally enter the S1300 middle pressing step: carry out the middle The pressed dry raw tea is pressed once in the middle of the stone mill; the entire pressing process takes 2 minute...

Embodiment 3

[0027] According to an embodiment of the present invention, the stone mill pressing method of Pu'er tea is carried out in the following steps: first carry out S1100 weight loading step: weigh 357 grams of dry raw tea into a cylinder and fumigate in steam, and dissolve the tea after steaming Put the tea gel into a cloth bag and knead it into a round cake, put it under the stone mill, and load 50 kg of weight vertically on the stone mill. The diameter of the stone mill is 33.5cm, the thickness of the stone mill is 15.5cm, and the weight of the stone mill It is 30Kg; then carry out the S1200 peripheral pressing step, press the weight-loaded dry raw tea along the outer periphery of the stone mill, press 4 times at the front, back, left, and right sides of the stone mill, and then shake it clockwise for a circle; finally enter the middle pressing step of S1300: put After intermediate pressing, the dried raw tea is pressed once in the middle of the stone mill; the entire pressing pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com