A kind of shape memory rigid polyurethane foam medical splint material and preparation method thereof

A technology of rigid polyurethane and foaming materials, which is applied in the manufacturing field of rigid polyurethane foamed medical splint materials, can solve the problems of poor air permeability, high density, slow deformation memory speed, etc. The effect of process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

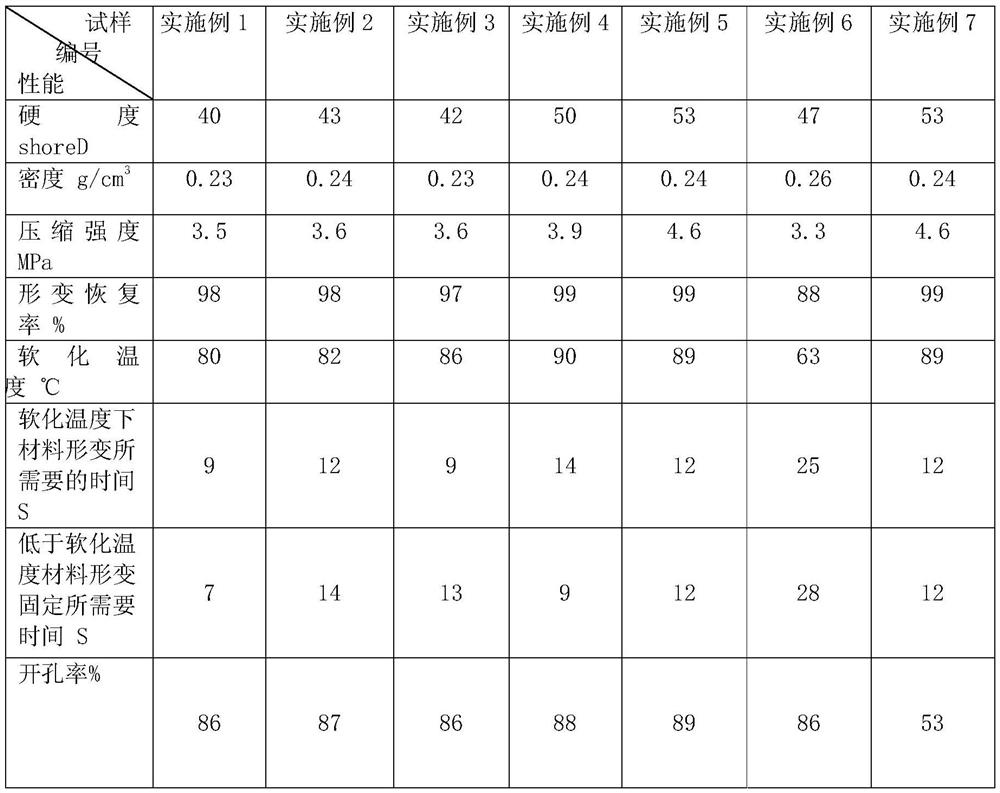

Examples

Embodiment 1

[0072] Component A (isocyanate component): Obtained according to the following preparation method: by weight percentage, 32.4% of polytetrahydrofuran ether polyol (PTMG-1000) with 2 functionalities and molecular weight of 1000, diphenylmethane diisocyanate (MDI-100 ) 67.6%, reacted at 80°C for 2 to 3 hours to obtain a prepolymer with an isocyanate content of 20%.

[0073] Component B (polyol component): obtained according to the following preparation method: in parts by weight, polytetrahydrofuran ether polyol (PTMG-2000) 20 with a molecular weight of 2000, polyethylene adipate polyol with a molecular weight of 2000 (PEA-2000) 80, chain extender EG 5.0, chain extender TMP 4.0, catalyst stannous octoate 0.05, catalyst A33 0.05, antioxidant 1010 0.5, blowing agent deionized water 0.4, blowing agent HCFC-141b 5 , foam stabilizer DC193 0.5, cell opener Ortegol 501 2, stir well with a high-speed mixer.

[0074] The isocyanate component and the polyol component are mixed and reacte...

Embodiment 2

[0076] Component A (isocyanate component): Obtained according to the following preparation method: by weight percentage, 32.4% of polycaprolactone polyol (210) with 2 functionalities and a molecular weight of 1000, diphenylmethane diisocyanate (MDI-100) 67.6%, react at 80°C for 2 to 3 hours to obtain a prepolymer with an isocyanate content of 20%.

[0077] Component B (polyol component): Obtained according to the following preparation method: in parts by weight, polyethylene adipate polyol (PEA-2000) 40 with a molecular weight of 2000, polyphthalic anhydride polyester polyol with a molecular weight of 1000 Alcohol (PD-110LV) 60, chain extender EG 4, chain extender DMTDA 3, catalyst stannous octoate 0.05, catalyst A33 0.05, antioxidant 1010 0.5, blowing agent deionized water 0.4, blowing agent cyclopentane 5. Foam stabilizer AK-8804 0.5, cell opener AK-9901 0.9, stir evenly with a high-speed mixer.

[0078]The isocyanate component and the polyol component are mixed and reacted...

Embodiment 3

[0080] Component A (isocyanate component): Obtained according to the following preparation method: by weight percentage, 19.67% of polycaprolactone polyol (210) with 2 functionalities and a molecular weight of 1000, diphenylmethane diisocyanate

[0081] (MDI-100) 48.03%, carbodiimide modified diphenylmethane diisocyanate

[0082] (MDI-100LL) 32.30%, react at 80°C for 2 to 3 hours to obtain a prepolymer with an isocyanate content of 25%.

[0083] Component B (polyol component): obtained according to the following preparation method: in parts by weight, polycaprolactone polyol (210) 60 with a molecular weight of 1000, polycaprolactone polyol (220) 40 with a molecular weight of 2000, Chain extender BDO 3.5, chain extender DEOA3.5, catalyst stannous octoate 0.05, catalyst A33 0.05, antioxidant 1010 0.5, foaming agent deionized water 0.4, foaming agent HCFC-141b 5 foam stabilizer DC193 0.5, Cell opener Ortegol 501 1, stir well with a high-speed mixer.

[0084] The isocyanate comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com