Method for separating and purifying graphene quantum dots by utilizing molecular sieve

A technology of graphene quantum dots and molecular sieves, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of organic extractant hazards, difficulty in selecting organic extractants, etc., and achieve short operation time and great application value , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1, weighing 1 g of FDU-12 molecular sieve with an average pore diameter of 10 nm.

[0024] Step 2, cleaning FDU-12 molecular sieve: first add 100ml deionized water, ultrasonically disperse for 20 minutes; then add 100ml absolute ethanol, ultrasonically disperse for 20 minutes.

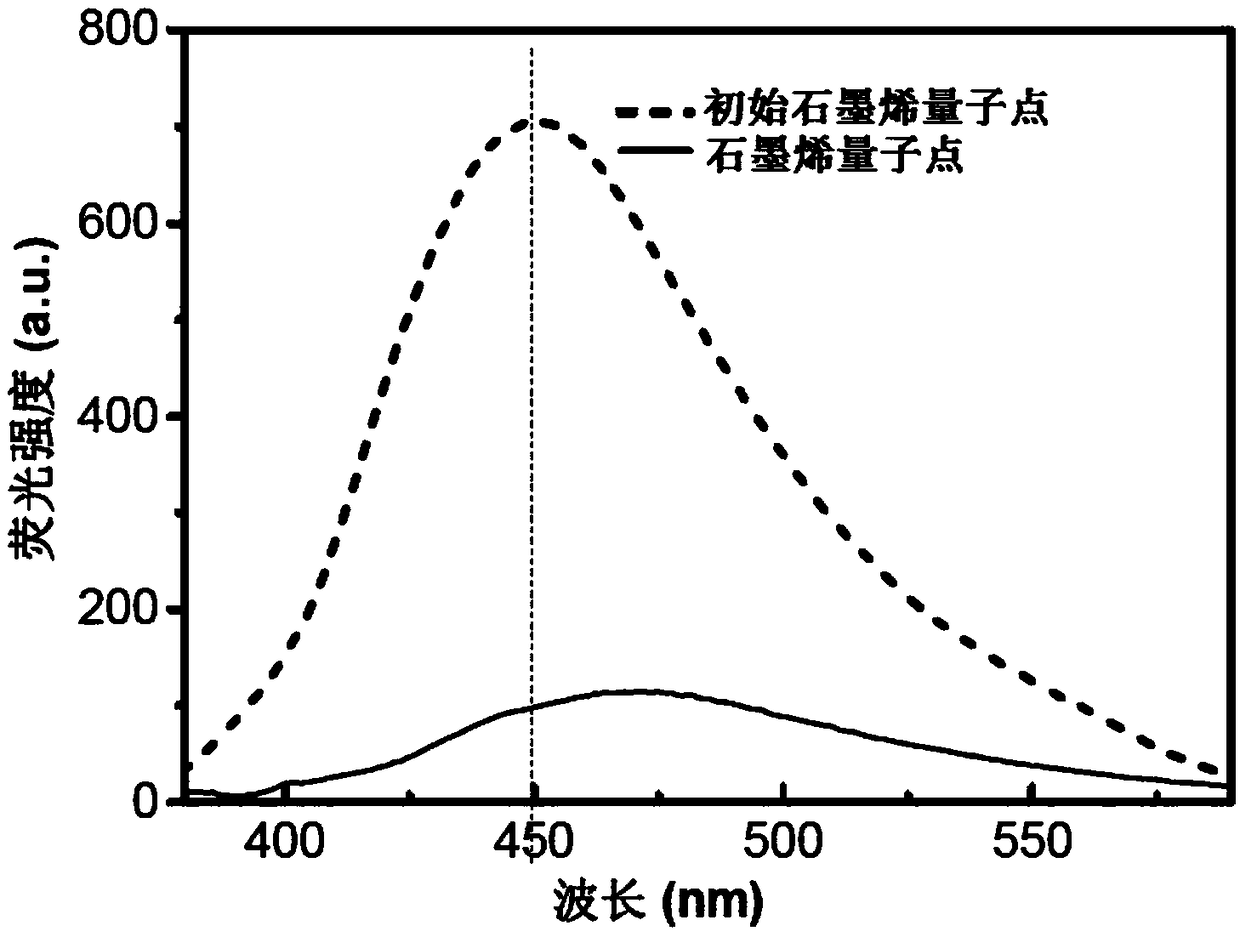

[0025] Step 3: Weigh 100 g of the initial graphene quantum dot solution, add the cleaned FDU-12 molecular sieve, and ultrasonically disperse for 30 minutes at room temperature to obtain the reactant. The reactants include graphene quantum dots-molecular sieves, graphene quantum dots of other sizes and impurities.

[0026] Step 4, centrifuging the reactants to obtain graphene quantum dot-molecular sieves containing graphene quantum dots.

[0027] Step five, clean the graphene quantum dot-molecular sieve with 100ml ethanol, and centrifuge to remove ethanol.

[0028] Step 6, adding chloroform to the cleaned graphene quantum dot-molecular sieve as a desorbing agent, heating to 70° C. for 30 m...

Embodiment 2

[0039] Step 1, weighing 1 g of SBA-15 molecular sieve with an average pore diameter of 5 nm.

[0040] Step 2, cleaning SBA-15 molecular sieve: first add 100ml deionized water, ultrasonically disperse for 20 minutes; then add 100ml absolute ethanol, ultrasonically disperse for 20 minutes.

[0041] Step 3: Weigh 10 g of the initial sulfur-nitrogen co-doped graphene quantum dot solution, add the cleaned SBA-15 molecular sieve, and ultrasonically disperse for 30 minutes at room temperature to obtain the reactant. The reactants include sulfur and nitrogen co-doped graphene quantum dots-molecular sieves, sulfur and nitrogen co-doped graphene quantum dots of other sizes and impurities.

[0042] Step 4, centrifuging the reactants to obtain sulfur and nitrogen co-doped graphene quantum dots-molecular sieves containing sulfur and nitrogen co-doped graphene quantum dots.

[0043] Step five, wash the sulfur and nitrogen co-doped graphene quantum dot-molecular sieve with 100ml ethanol, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com