Skin folding machine with cutting machine

A cutting machine and leather machine technology, applied in the field of leather folding machines, can solve the problems of affecting the cutting speed, slow speed, and high labor intensity, and achieve the effects of stable and controllable performance, regular shape, and fast production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

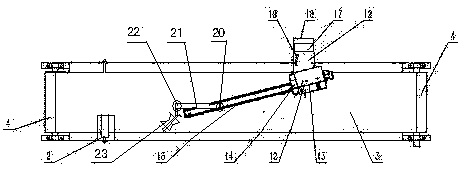

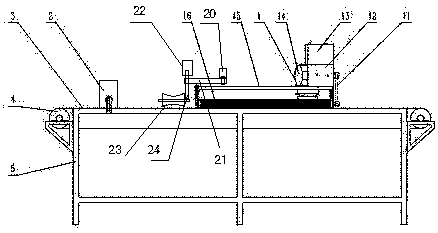

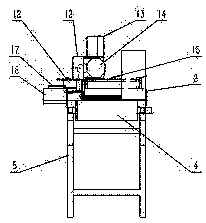

[0018] Figure: a leather folding machine with a cutting machine, including a frame 5, a conveyor belt 3, and a leather folding driver 1, which is characterized in that: the conveyor belt 3, the leather folding driver 1 are installed on the frame, and the folding leather driver 1 is also It includes a fixed seat, a folding skin driving motor 14, a motor fixing frame 12, an electric control box 13, a folding top roller frame 15, and a folding top roller 16. The block 17 is fixed on the lower block 18, and the upper block 17 can adjust its relative position to the lower block 18 by loosening the fixing bolts. The motor fixing frame 12 is installed on the upper block 17 to realize the adjustment of the horizontal direction of the folding skin driving machine 1 and the transmission belt 4 Relative position; the motor fixing frame 12 is installed on the upper block 17 by two bolts, the motor fixing frame 12 has an arc groove 19, and one of the fixing bolts 110 is installed through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com